800mm Wide Deburring Machine for Laser-Cut Sheet Metal

The 800mm wide deburring machine is a high-performance industrial solution designed specifically for post-processing of laser-cut sheet metal parts. It efficiently removes burrs, rounds edges, and eliminates oxide layers, ensuring a smooth, uniform finish while enhancing safety and surface quality.

✅ Key Applications

Post-laser cutting deburring

Edge rounding (up to 2mm radius)

Oxide layer removal

Surface finishing of steel, stainless steel, and aluminum

Technical Specifications

| Item | Details |

| Material Compatibility | Steel, Aluminum, Stainless Steel |

| Processing Type | Edge Rounding, Deburring, Oxide Removal |

| Material Thickness | 0 – 80 mm |

| Max. Material Width | 800 mm |

| Min. Workpiece Size | 50 x 50 mm |

| Workpiece Holding System | Magnetic (Vacuum optional) |

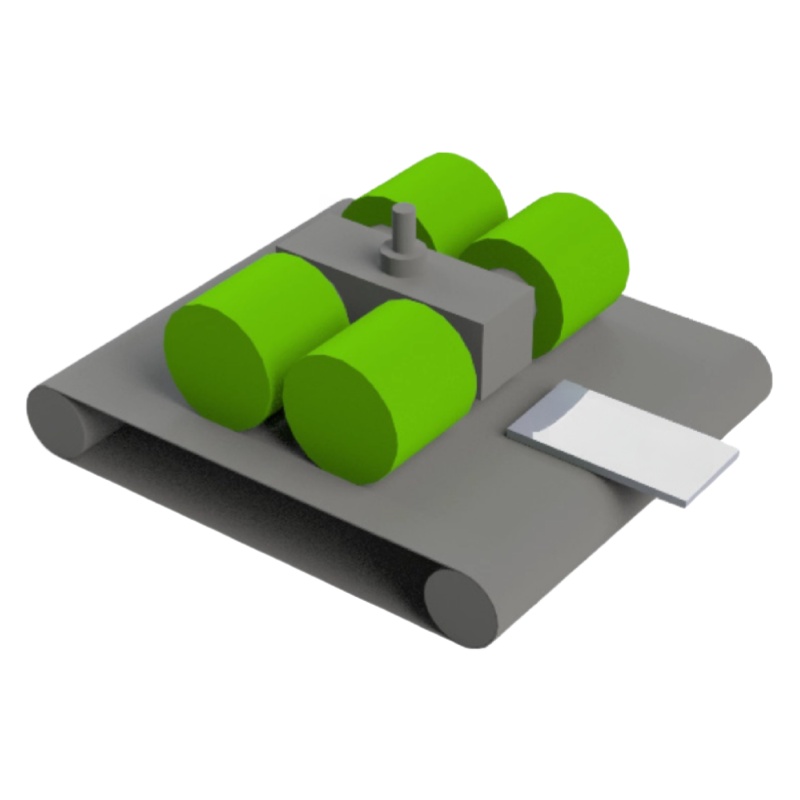

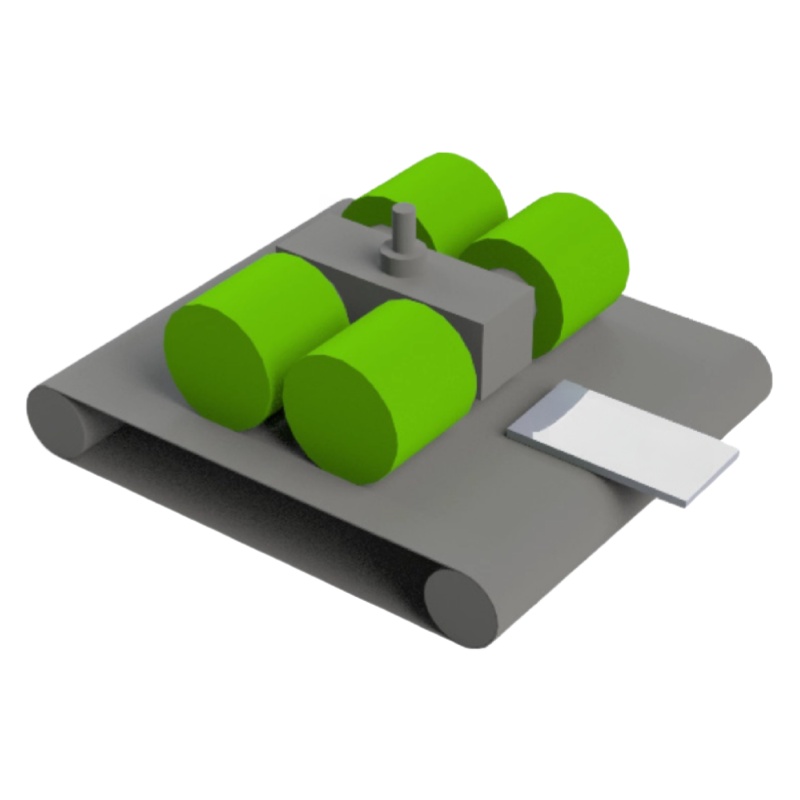

| Flap Wheel Size | Ø300 x 300 mm |

Main Features

Wide Processing Width: 800mm working width covers most standard sheet sizes used in industrial production.

Flexible Material Handling: Handles a wide range of thicknesses and small parts, suitable for laser, plasma, and punching processes.

Stable Holding System: Equipped with a strong magnetic bed for ferrous materials; vacuum table optional for non-ferrous parts like aluminum or copper.

Efficient Deburring: Large-diameter flap wheels (Ø300mm) provide consistent surface finishing, even on complex geometries and internal holes.

Safe and Clean Operation: Optional integration with dust collection system ensures a clean working environment.

Applications of the 800mm Wide Deburring Machine

This deburring and edge rounding machine is widely used in various industries where laser-cut sheet metal requires precise post-processing. It provides consistent, high-quality surface treatment and is ideal for improving part safety, coating adhesion, and aesthetic finish.

Typical Applications:

Laser Cutting Workshops

Removes burrs and oxide layers after fiber or CO₂ laser cutting, ensuring clean and safe edges.

Metal Fabrication Plants

Perfect for shops processing large volumes of steel, stainless steel, and aluminum components.

Precision Sheet Metal Processing

Prepares parts for painting, powder coating, or welding by creating rounded, oxide-free edges.

Electrical Cabinet Manufacturing

Ensures internal parts like doors and panels have smooth edges, reducing injury risk and improving assembly fit.

Automotive & Aerospace Industries

Critical for components where safety, surface finish, and performance are closely linked to edge quality.

Signage and Decoration Industry

Provides high-quality finishing on visible surfaces of aluminum and stainless steel plates.

Kitchen Equipment and Appliances

Improves hygiene and appearance on stainless steel products by removing sharp edges and finishing surfaces.

✅ Processes Supported:

Deburring (laser, plasma, flame-cut parts)

Edge rounding (up to R2)

Oxide removal

Surface conditioning and fine finishing