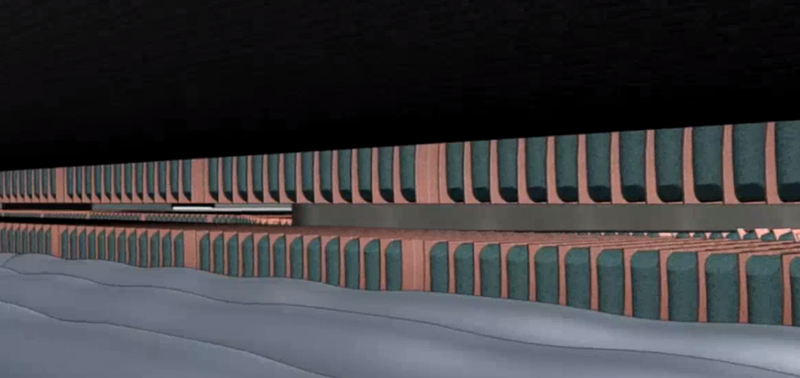

Double sided deburring of small parts - Deburring and uniform edge rounding on all sides of parts, both on outer- and inner contours, in a single pass

Deburring machine for grinding, deburring and edge rounding of punched, laser and high definition plasma cut parts in one single pass

Deburring and edge rounding of laser, plasma and oxy fuel cut parts on both sides in one single pass

Equipment processing width : 800 mm、1000mm、1350mm、1600mm、2000mm、2200mm、2500mm

Equipment processing thickness: 1-100 mn

Feeding speed: 0.5-8 m/min(variable frequency adjustable)

Optional feeding mode:

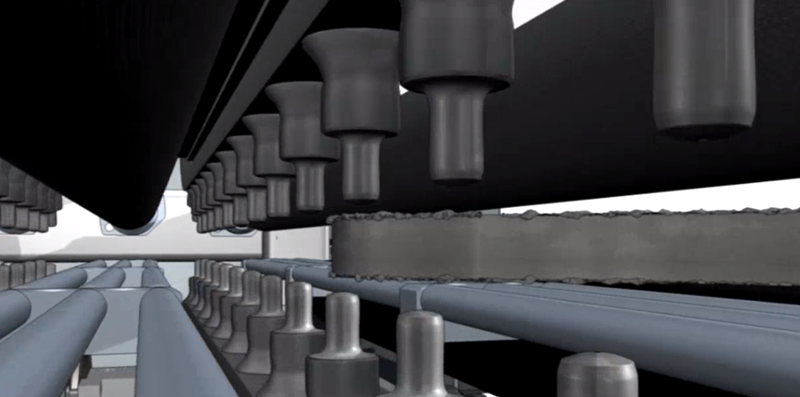

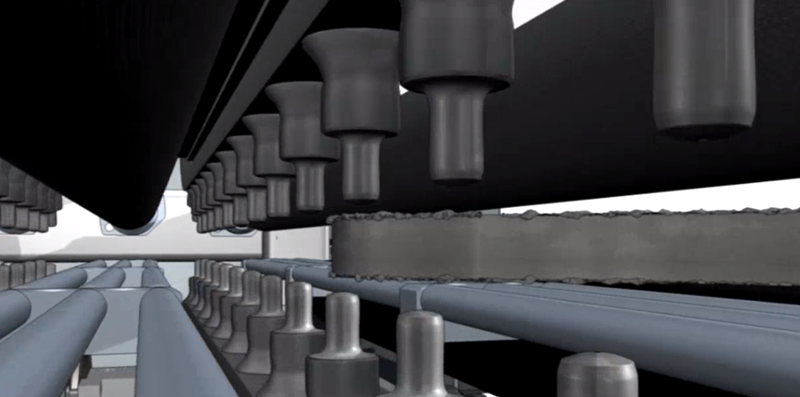

1. Conveyor belt + rubber roller clip feeding (for ordinary workpieces.Workpiece length ≥ 150 mm)

2.Strong permanent magnet adsorption conveying material for carbon steel workpieces. Workpiece size ≥ 30 mmx30 mm)

3.Vacuum negative pressure adsorption conveying feeding (for stainless steel plate, copper platealuminum plate, etc.)is not magnetically

adsorbed.Workpiece size ≥ 50 mmx50 mm)

Rubber roller + rubber roller clip feeding

DPG Machines Overview

DPG machines are designed for efficient deburring and processing of sheet metal parts, including laser-cut and stamped parts. The L Series is particularly notable for its capability to handle two-sided processing, offering significant time savings and operational flexibility.

Key Features of the L Series

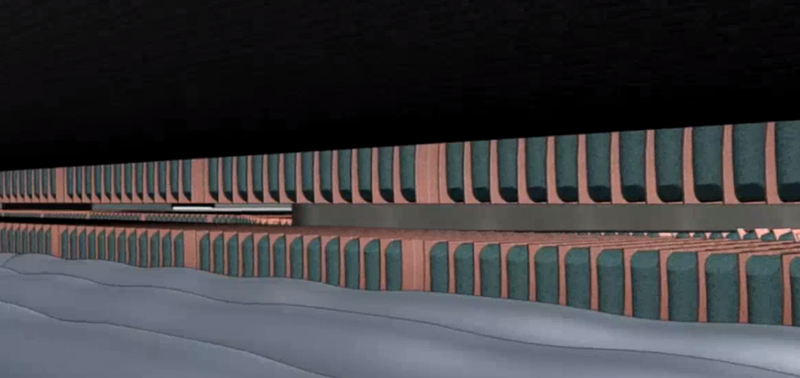

Dual-Sided Processing: Equipped with three units each on the top and bottom, enabling simultaneous processing of both sides of the workpiece.

Versatility in Material Handling: Can process stainless steel, steel, aluminum, and non-ferrous metal workpieces.

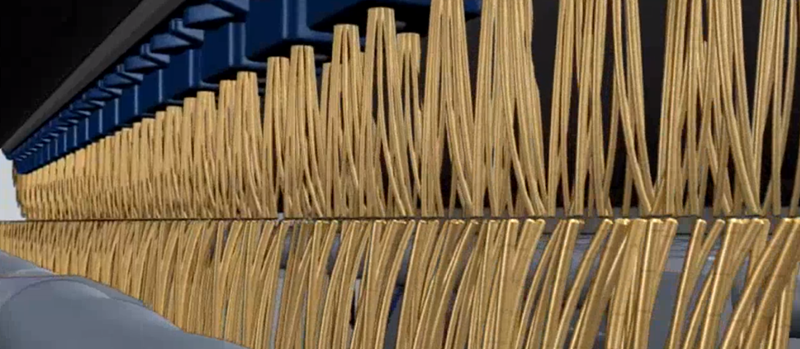

Edge Rounding: Efficient edge rounding in one operation, improving part quality and safety.

Time Efficiency: Two-sided processing and edge rounding can save up to 60% of the time compared to single-sided processing.

Automation Integration: Easily connectable to automation solutions or integrable into production lines, enhancing workflow efficiency.

Ergonomic Design: Ensures comfortable operation and a pleasant working environment.

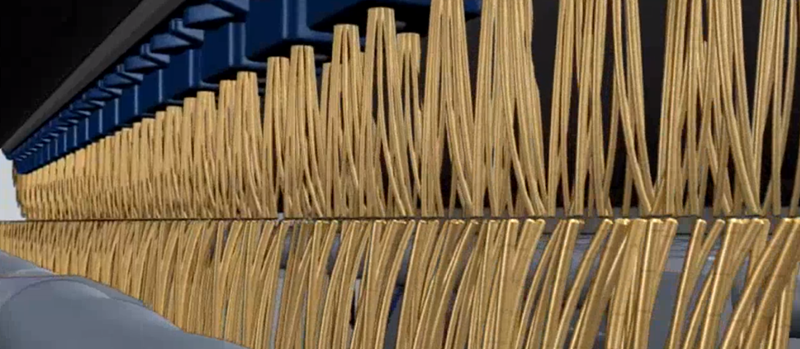

Pollution Control: Minimizes pollution, dust, and noise, contributing to a safer and cleaner workspace.

Applications

Deburring Sheet Metal: Efficiently removes burrs from sheet metal parts.

Processing Laser Parts: Suitable for handling laser-cut parts with precision.

Stamping Parts: Effective in processing stamped parts, ensuring smooth edges and surfaces.

Versatile Material Processing: Capable of handling various materials, including stainless steel, steel, aluminum, and non-ferrous metals.

Advantages

Time Savings: Two-sided processing cuts down operation time significantly.

Automation Ready: Designed for easy integration with automation solutions, improving production efficiency.

Ergonomic and Clean Operation: User-friendly design with minimal dust and noise pollution.

High-Quality Finish: Ensures consistent and high-quality deburring and edge rounding results.

Technical Data

Processing Units: Three units each on the top and bottom.

Material Compatibility: Stainless steel, steel, aluminum, non-ferrous metals.

Processing Options: Upper side, lower side, or both sides simultaneously.

Options and Accessories

Automation Solutions: Integration with automated production lines.

Dust Extraction Units: Ensures a clean working environment by removing harmful abrasive dust.

Rotating Cleaning Brushes: For cleaning conveyor belts, ensuring consistent performance.

Conclusion

DPG's L Series machines offer a versatile, efficient solution for deburring and processing sheet metal parts, making them ideal for industries requiring high-quality finishes and operational efficiency. With dual-sided processing and easy integration into automated workflows, these machines provide substantial time savings and ergonomic benefits, contributing to a cleaner, safer, and more productive working environment.