Deburring & Edge Rounding

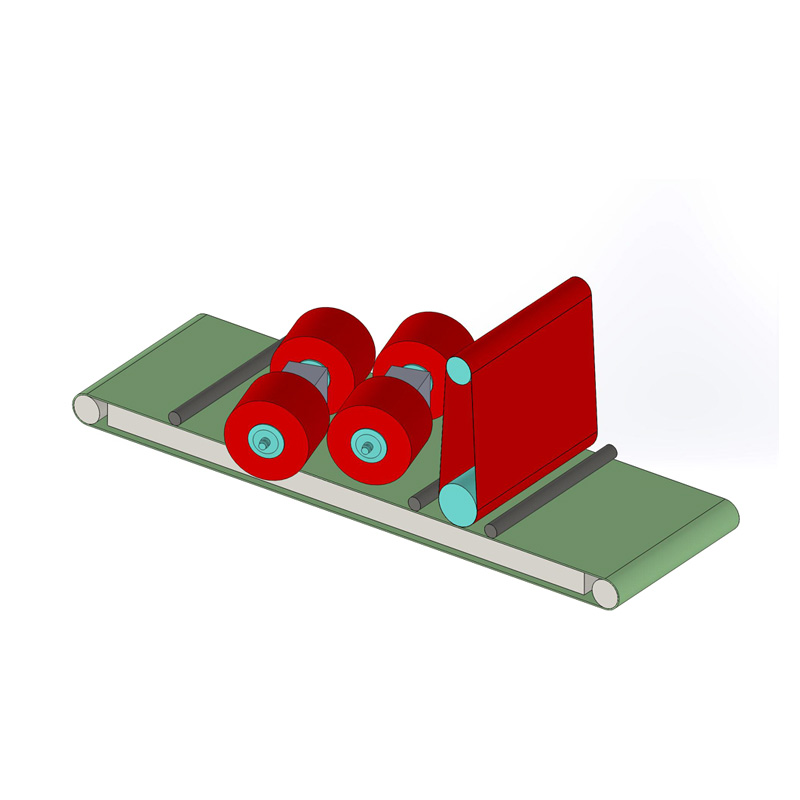

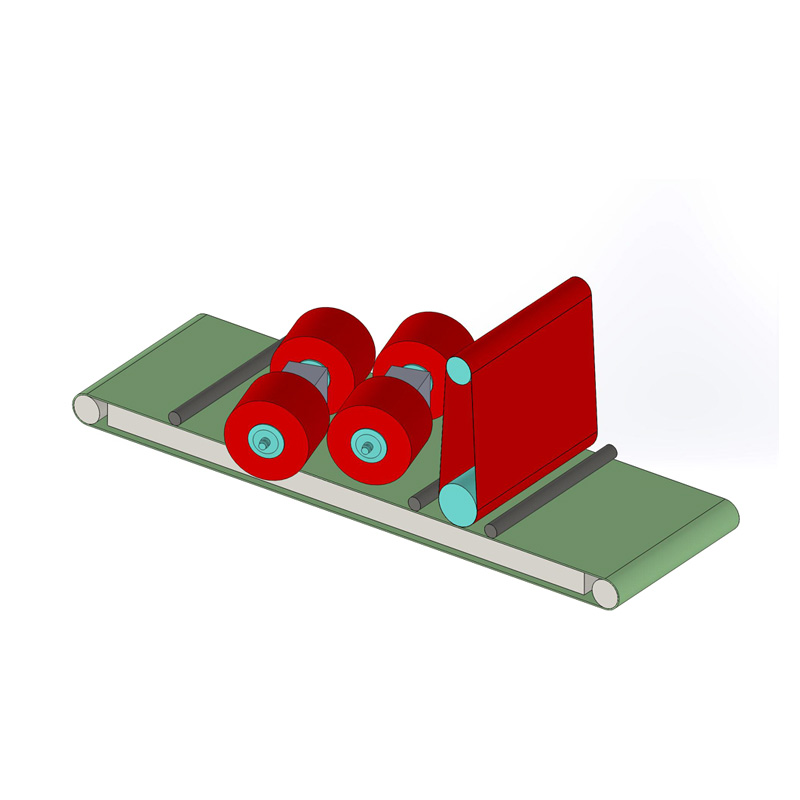

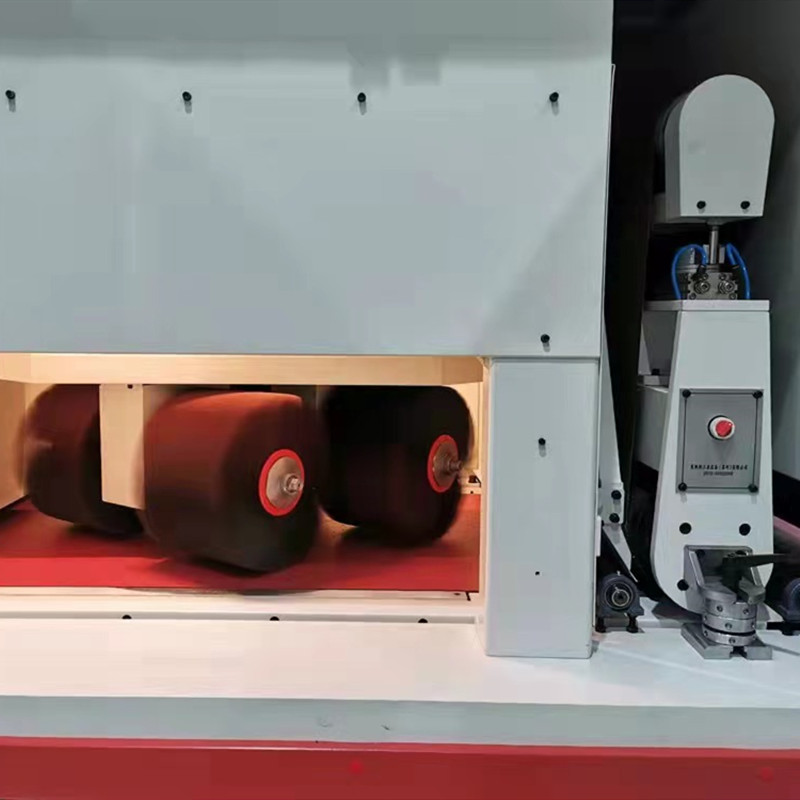

Rotary Brush Head: This component features brushes that rotate to smooth out burrs and round edges uniformly.

Multifunction Vertical Brushes: Vertical brushes that can adjust to the contours of the workpiece, providing consistent deburring and edge rounding.

Orbital Multi-Brushes (Planetary): These brushes move in orbital patterns to cover a wider area and achieve even deburring and edge rounding on complex shapes.

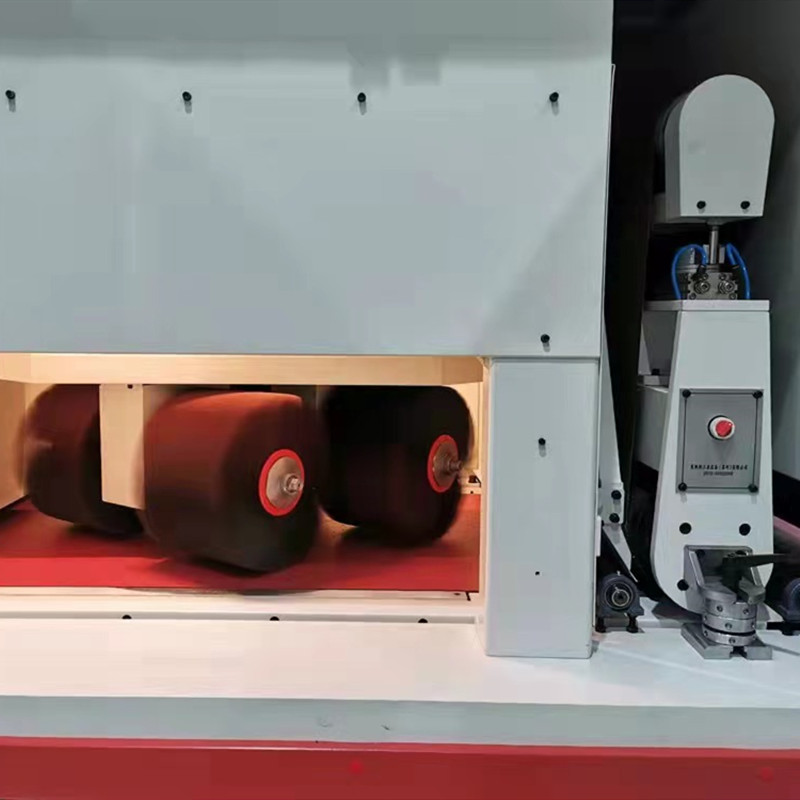

Deburring machines metal polishing sanding machine for finishing, 360° deburring, edge rounding up to a 2mm radius, and oxide removal with an 800mm working width, you need a versatile and robust machine.

Machine Specifications

Working Width: 800mm

Processing Thickness: 0.5~80mm

Minimum Processing Size: 50mm×50mm

Machine Power: 29.5KW

Sand t belt size Φ 1910mm ×800mm

Sand Rolling Brush Size: Φ 300mm × 300mm

Delivery Speed: 0.5~6m/min

Sand Belt Line Speed: 12m/s

Rolling Brush Rotation Speed: Adjustable frequency conversion, 500~1400r/min

Rolling Brush Public Speed: 1~15r/min

Number of Roller-Brush Planetary Revolution Shaft Heads: 1

Number of Rolling-Brush Planetary Rotation Shaft Heads: 4

Machined Thickness Servo Adjustment Precision: 0.01mm

Rolling Brush Compensation Servo Adjustment Precision: 0.01mm

Grinding Consumables: Sand belt

Dust Extraction Air Volume: 4000m³/h

Contour Size of the Unit: Length 3050mm, width 1950mm, height 2150mm

Weight: Approximately 2.5T

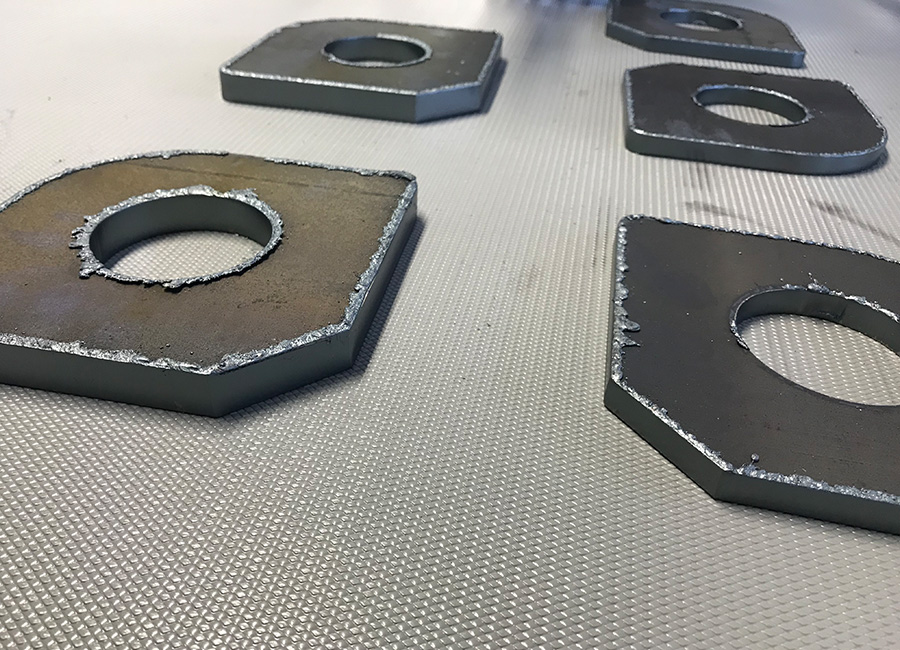

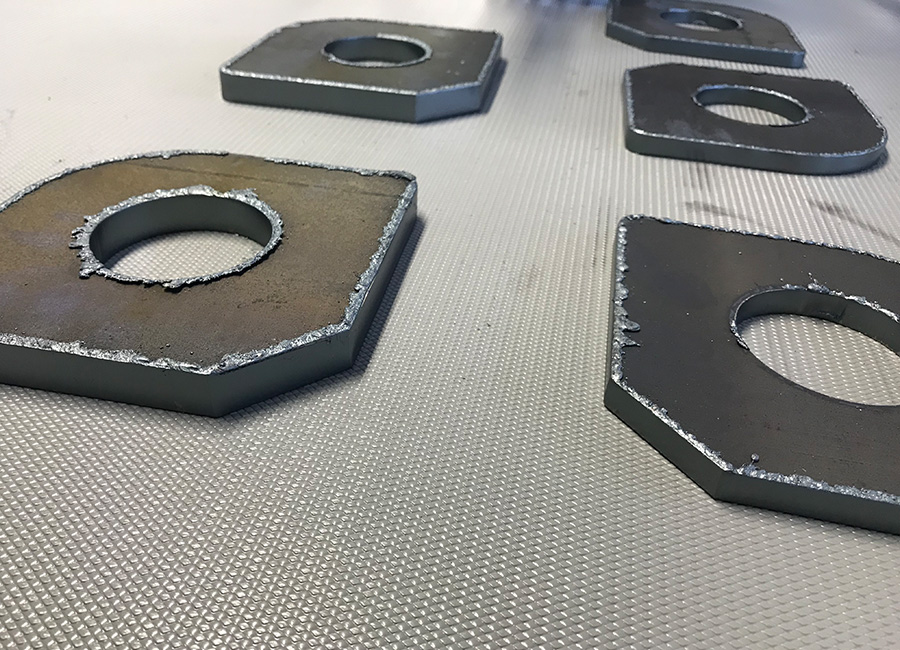

360° Deburring

Edge Rounding up to 2mm Radius

Oxide Removal

Finishing

Advanced Brush System

Rotary Brush Head: Ensures even deburring and edge rounding.

Multifunction Vertical Brushes: Adapt to various part shapes and sizes.

Orbital Multi-Brushes (Planetary): Provide comprehensive coverage and consistent results.

Longitudinal Brushes: Perfect for long and flat surfaces.

Cylinder Brushes: Ideal for robust deburring and finishing actions.

Electronic Sectioned Pads: Provide precision control for delicate finishing tasks.

Automated Adjustments

Efficient Dust Extraction

Example Models

Timesavers 42 Series RB

Features: This model offers rotary brush heads, adjustable speed settings, and advanced dust extraction. It's designed for deburring, edge rounding, oxide removal, and finishing.

Lissmac SBM-L G1S2

Features: Known for double-sided processing, it can handle deburring, edge rounding, and oxide removal with high precision. Suitable for parts with complex geometries and high surface quality requirements.

Costa Levigatrici MD-WD Series

Applications

Automotive Parts: Ensuring smooth and safe edges.

Aerospace Components: High precision and quality finishes.

Metal Fabrication: General deburring and edge rounding.

Construction Materials: Preparing structural components.