Product Scope of Application:

Suitable for flat plate parts, including carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, rubber, and plastic materials.

Equipment Function:

The equipment is designed to process workpieces made by the following cutting methods:

Laser cutting

Shearing

Punching

Waterjet cutting

Plasma cutting

Main functions include:

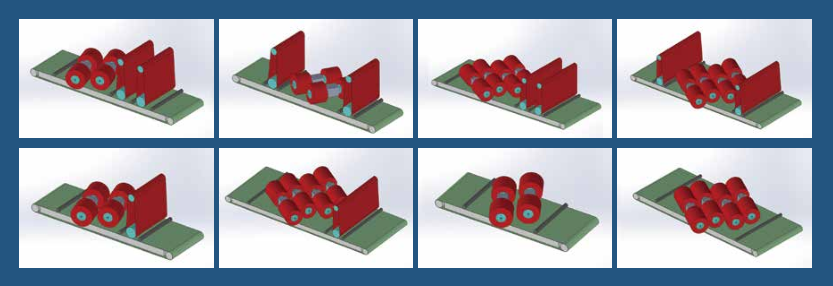

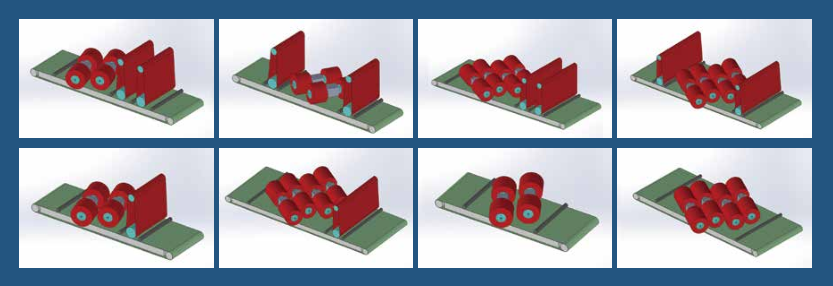

Equipment Combination:

The equipment uses a wide abrasive belt and universal roller brush in either single or multiple combination structures to ensure effective surface treatment for various types of workpieces.

Equipment Structure:

Processing width: 450mm, 800mm, 1000mm, 1350mm, 1600mm

Processing thickness: 0.5-80 mm

Feeding speed: 0.5-6 m/min (variable frequency adjustable)

Main Technical Parameters of the Equipment

| Parameter | Specification |

| Processing width | ≤780mm |

| Processing thickness | 0.5~80mm |

| Minimum processing size | 50mm×50mm |

| Total machine power | 22KW |

| Sanding roller brush size | Φ300mm×300mm |

| Conveyor feeding speed | 0.5~6m/min (variable frequency adjustable) |

| Brush rotation speed | 8~26m/s (variable frequency adjustable) |

| Brush planetary rotation speed | 1~15r/min (variable frequency adjustable) |

| Number of planetary rotation heads | 1 |

| Number of planetary self-rotation heads | 4 |

| Servo adjustment precision for processing thickness | 0.01mm |

| Grinding consumables | Roller brush |

| Dust removal air volume | 3000m³/h |

| Equipment dimensions | Length 2350mm × Width 1750mm × Height 2150mm |

| Total machine weight | Approximately 1.6T |

Optional Feeding Modes:

Strong permanent magnet adsorption conveyor: Suitable for carbon steel workpieces. Workpiece size ≥30 mm×30 mm.

Vacuum negative pressure adsorption conveyor: Suitable for stainless steel, copper, and aluminum plates that are not magnetically attracted. Workpiece size ≥50 mm×50 mm.

Additional Technical Details:

Four-column synchronous lifting system: Independently controls the position of the roller brush with servo control, providing a lifting accuracy of 0.01 mm.

NC PLC touch screen: Allows easy adjustment of processing parameters.

Dust collection system: Can be equipped with a wet vacuum cleaner or industrial pulse vacuum cleaner to manage grinding dust, ensuring environmentally-friendly production.

This equipment is capable of meeting various processing requirements and is widely applicable for surface treatment operations such as deburring, polishing, and wire drawing for both metal and non-metal materials.