1600mm Automatic Double-Sided Sanding Machine:

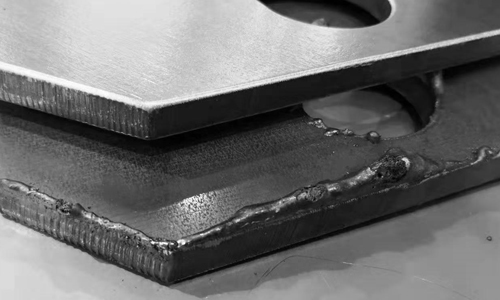

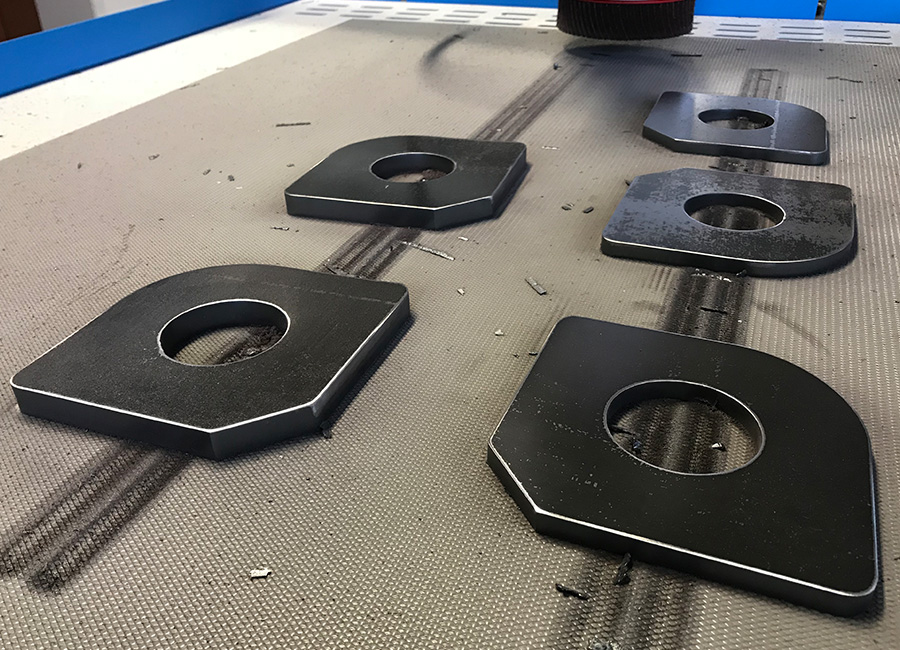

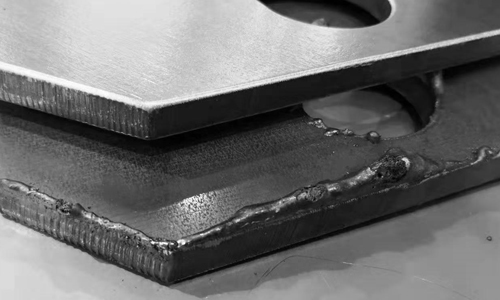

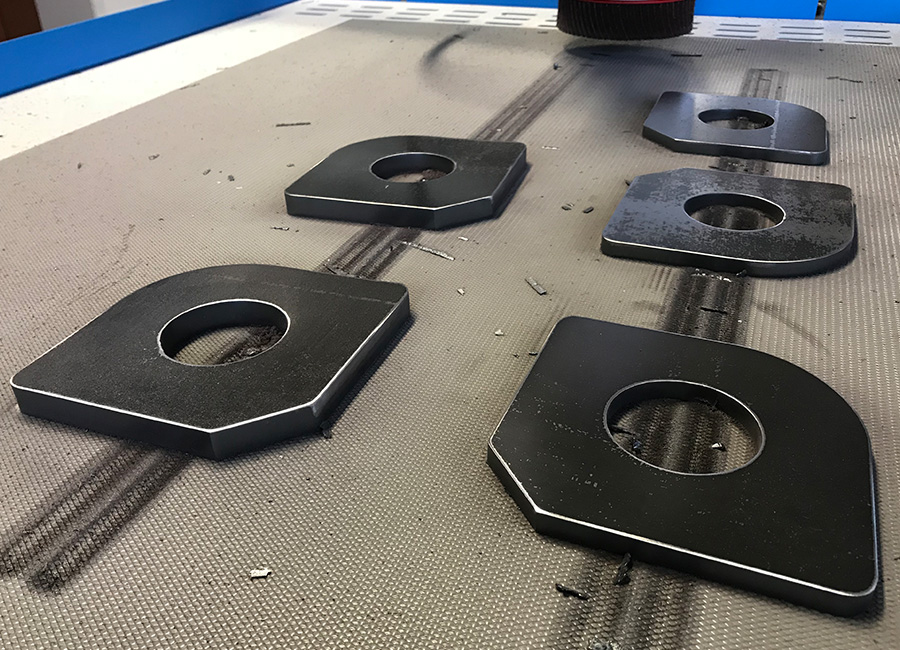

Grinding and deburring machines are engineered to perform simultaneous deburring and edge rounding of workpieces in a single operation, optimizing efficiency in sheet metal processing. These machines are ideal for handling sheet metal parts, laser-cut components, and stamped parts across various materials, including stainless steel, steel, aluminum, and non-ferrous metals.

The flexibility of these machines allows for the processing of workpieces on the upper side, lower side, or both sides at once, offering a comprehensive solution for deburring and edge rounding. This versatility makes them well-suited for applications requiring smooth, clean edges and a high-quality finish on parts made from different types of metals.

The sanding system includes two primary grinding heads:

The first grinding head utilizes a hammering mechanism with a hammer head size of φ25mm × 50mm, capable of operating at line speeds between 3-8m/s.

The second and third grinding heads focus on belt sanding, using grinding rubber drive wheels with a diameter of Φ280mm. The sand belts, measuring 6710mm in length, operate at speeds ranging from 10-25m/s, offering flexibility and precision.

For material handling, the transport system uses rollers of Φ142mm in diameter, with an adjustable conveying speed of 0.5-6m/min. The machine also includes a 7.5KW wet dust collector for effective dust management, ensuring a cleaner and safer work environment.

With a total weight of approximately 17.9 tons, this machine is engineered for stability, efficiency, and reliability in high-demand manufacturing environments.

2.2 Basic Technical Parameters of the Equipment

| No. | Item | Parameters |

| 1 | Maximum Processing Width | 1500mm |

| 2 | Processing Thickness | 1-100mm |

| 3 | Sand Belt Size | Inner circumference 6710mm × Width 80mm |

| 4 | Hammer Baseband Size | BJ Quinary type, outer circumference 6377mm |

| 5 | Total Power of the Equipment | 160KW (main engine) |

| 6 | Hammer Main Motor | 15KW-6P (frequency adjustable speed) |

| 7 | Belt Main Motor | 15KW-4P (frequency adjustable speed) |

| 8 | Total Weight of the Equipment | Approximately 17.9T |

2.3 Main Component Parameters

| No. | Item | Parameters |

| 1 | First Grinding Head |

|

| 1.1 | Hammer Head Size | φ25mm × 50mm |

| 1.2 | Hammer Line Speed | 3-8m/s (frequency control) |

| 1.3 | Hammer Belt Size | BJ Quinary type, outer circumference 6377mm |

| 1.4 | Hammer Belt Drive Main Motor | 15KW-6 poles |

| 1.5 | Hammer Lifting Motor | 750W servo motor |

| 2 | Second and Third Grinding Heads |

|

| 2.1 | Grinding Rubber Drive Wheel Diameter | Φ280mm, rubber hardness 70° |

| 2.2 | Belt Line Speed | 10-25m/s (frequency control) |

| 2.3 | Sand Belt Size | Inner circumference 6710mm × Width 80mm |

| 2.4 | Sand Belt Deviation Detection | Limit switch |

| 2.5 | Sand Belt Correction | Automatic correction |

| 2.6 | Belt Tension | Pneumatic automatic tension |

| 2.7 | Abrasive Belt Main Motor Power | 15KW-4 poles |

| 3 | Transport System |

|

| 3.1 | Roller Diameter | Φ142mm, rubber hardness 80° |

| 3.2 | Drive Mechanism | Worm gear drive (stable and reliable) |

| 3.3 | Transmission Speed | 0.5-6m/min (frequency control) |

| 3.4 | Transport Main Motor | 5.5KW-4 poles × 2 |

| 4 | Dust Collection System | 7.5KW wet dust collector |

The two-sided sheet metal processing and edge rounding machine is designed for efficient, simultaneous treatment of both sides of sheet metal. It offers a maximum working width of 1000mm, 1600mm, or 2500mm, depending on the model, and can handle material thicknesses ranging from 0.5mm to 80mm.

This machine is highly suitable for applications requiring precision deburring and edge rounding, providing a smooth finish on both sides of the workpiece in a single pass. It is ideal for processing a variety of materials, such as stainless steel, aluminum, and other non-ferrous metals, across a wide range of thicknesses.

two-sided sheet metal processing and edge rounding machines:

1. What materials can the machine process?

The machine is suitable for processing stainless steel, aluminum, steel, and non-ferrous metals. It is designed to handle a wide range of materials for deburring, edge rounding, and finishing.

2. What is the maximum working width available?

The machine comes with three available working widths: 1000mm, 1600mm, and 2500mm, providing flexibility for various sheet sizes.

3. What is the range of material thickness that can be processed?

4. Can the machine process both sides of the workpiece simultaneously?

5. Is it suitable for small parts or only large sheets?

6. Can I process laser-cut or stamped parts?

Yes, the machine is designed for deburring laser-cut parts, stamped parts, and sheet metal components. It efficiently removes burrs and rounds the edges in a single operation.

7. How does the machine ensure edge rounding?

8. Will the machine damage surfaces with protective coatings or galvanization?

9. Is there any dust collection system included?

10. What industries typically use this machine?

These machines are commonly used in industries such as automotive, aerospace, metal fabrication, machinery, and construction, where high precision and finishing quality are essential.