Fiber lasers are lasers that use rare-earth-doped glass fibers as gain media. Generally speaking, fiber laser is mainly composed of pump source, isolator, beam combiner, doped fiber and other components. The pump source is composed of one or more high-power laser diode arrays. The pump light emitted by it is coupled into the rare-earth element-doped fiber as the gain medium through a special pump structure, and the photons at the pump wavelength are absorbed by the doped fiber medium. , The population inversion is formed, and the stimulated light waves are fed back and oscillated by the cavity mirror to form laser output.

Compared with traditional solid and gas lasers, fiber lasers have good laser beam quality, high energy density, high electro-optical conversion efficiency, good heat dissipation performance, compact structure, maintenance-free, flexible transmission, and a wide range of processable materials. Known as the "third-generation laser." The electro-optical conversion efficiency of fiber lasers can reach 30%-35%, which is several times that of traditional solid and gas lasers, which is very energy-saving and environmentally friendly. The above-mentioned unparalleled technical advantages of fiber lasers make it widely used in the fields of engraving, marking, cutting, cladding, welding, surface treatment and other material processing fields, and are gradually replacing various physical processing, chemical processing, printing processing, etc. Traditional processing methods.

With the sale of the first Q-switched pulsed fiber laser by IPG in China in 2003, the development of commercial pulsed fiber lasers in the Chinese market officially kicked off. In 2004, the British SPI company based on the University of Southampton technology introduced the MOPA adjustable pulse width fiber laser into the Chinese market with the application of Apple products in the United States as an opportunity. For five years since then, the Chinese fiber laser market (Q-switched fiber laser and MOPA fiber laser) has been monopolized by these two laser companies by nearly 90%.

In 2008, Wuhan Ruike launched the first domestically-made commercial Q-switched pulsed fiber laser, which broke the monopoly of IPG in the United States. In 2009, Raycus Q-switched fiber lasers have begun to supply the market in small quantities, and initially obtained market approval for domestic lasers. At the beginning of 2009, Shenzhen JPT first launched the domestic commercial MOPA pulsed fiber laser, breaking the monopoly of SPI in the UK. Immediately afterwards, Shenzhen Chuangxin also launched commercial Q-switched pulsed fiber laser products to the market.

After these years of development, Wuhan Raycus has gradually occupied a large domestic market share in the field of pulsed fiber lasers in the field of medium and high power continuous fiber lasers, Raycus, JPT, and Chuangxin, and domestic fiber lasers are gradually regaining the Chinese market. .

As of the end of 2016, there were more than 20 domestic fiber laser brands, large and small, in the fierce competition with foreign brands, continuous innovation and breakthroughs, and the development speed is getting faster and faster. The main suppliers of domestic Q-switched pulsed fiber lasers include Wuhan Ruike, Shenzhen Chuangxin, Shenzhen Lianpin, Zhongke Guanghui, etc.; and Shenzhen JPT has further consolidated its MOPA fiber lasers with the unique technical advantages of MOPA pulsed fiber lasers. Leading position in the industry. Even in the field of traditional advantages of medium and high power continuous light fiber lasers, foreign products, a group of excellent domestic brands led by Wuhan Ruike has been formed: Shenzhen Chuangxin, Shenzhen Jept, Shanghai Feibo, Zhongke Guanghui, Shenzhen Lianpin, Haifu Photonics, etc.

According to a research report released by Strategies Unlimited, the total annual revenue of the global laser market in 2016 was 10.4 billion U.S. dollars, and it is expected to exceed 11.09 billion U.S. dollars in 2017. The annual revenue of global fiber lasers will increase by 8% in 2017, reaching US$1.4094 billion.

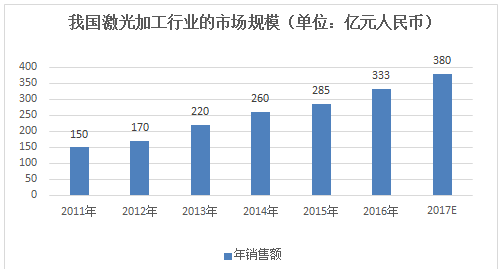

In 2016, China had more than 650,000 small and medium-power laser processing equipment used in laser welding, drilling, marking and other fields; the installed capacity of medium-power laser cutting machines and welding machines exceeded 10,000; the installed capacity of high-power laser machine tools exceeded 2,300 tower. Since 2011, the market scale of my country's laser processing industry has continued to grow, reaching 33.3 billion yuan in 2016. The details are as follows:

Data source: "Review and Prospect of China's Laser Industry in 2016", Laser Processing Professional Committee of Chinese Optical Society

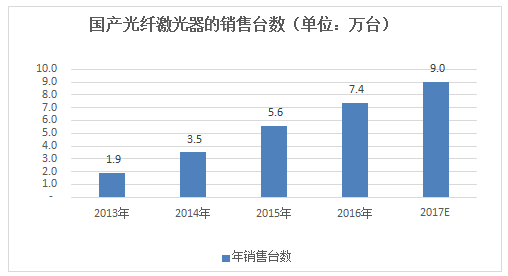

From 2013 to 2016, the number of domestic fiber lasers sold in my country has continuously increased year by year, as follows:

Data source: "Review and Prospect of China's Laser Industry in 2016", Laser Processing Professional Committee of Chinese Optical Society

Domestic low-power fiber lasers are mainly used in 3C product marking, micro-engraving and other fine processing fields. Domestic medium-power fiber lasers are widely used in the field of metal sheet cutting and welding, and sales are expected to maintain rapid growth in the next few years. Domestic high-power fiber lasers above kilowatts are mainly used in industrial fields such as laser cutting, perforation, welding, etc. With the advancement of light weight in my country's automobile industry and the application expansion of the composite material processing market, high-power lasers have good development prospects. In the next few years, the application hotspots of my country’s laser industry will include laser cleaning (paint removal, oil removal, oxide removal, screw cleaning, rust removal, weld cleaning, mold repair, etc.), laser welding, ultra-fast pulse picoseconds/ Femtosecond laser applications, etc.