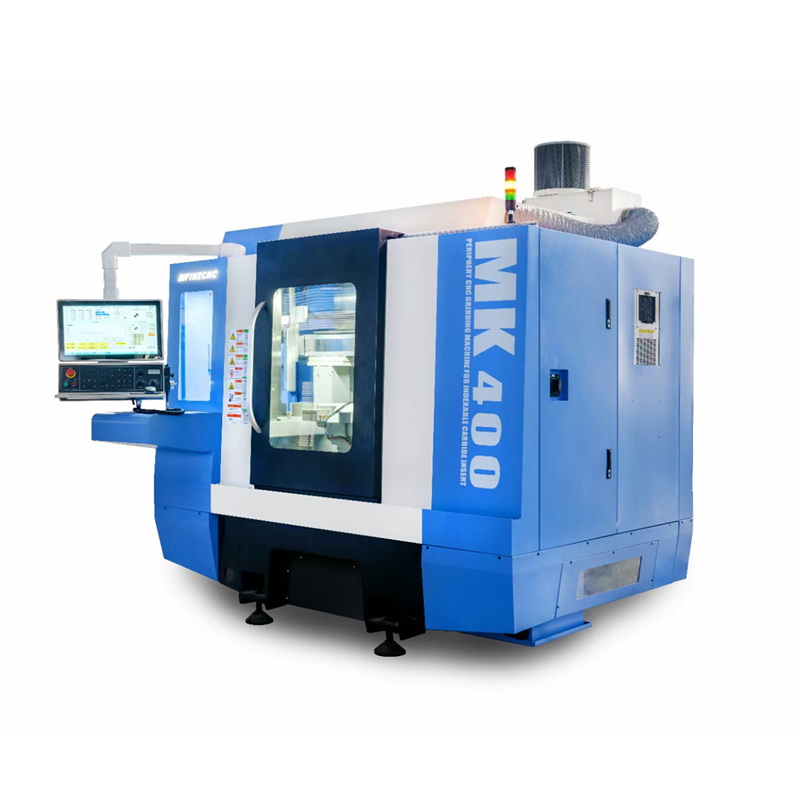

Fully Automatic 5 Axis Complex Insert Grinde

High-end Insert Periphery Grinder

350 series 5-axis control model. A High-end Insert Periphery Grinder that can process complex shapes that are impossible with conventional machines.

Fully automatic machining the periphery, dual-side lands for standard-series inserts, and fully automatic machining of 3D shapes

material Carbide, cermet, ceramic, CBN, PCD

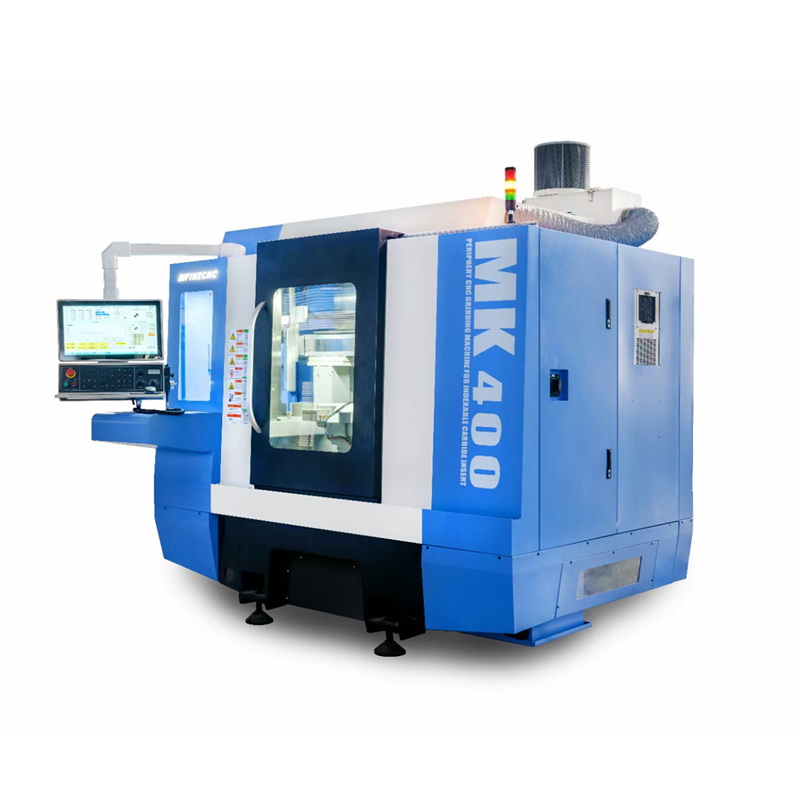

Rigidly structured Fully Automatic Combined Insert Periphery Grinder for further automation needs

Fully automatic processing of the periphery, dual-side lands for standard-series inserts

material Carbide, cermet, ceramic, CBN, PCD

strip grinding machine

knife bevel grinding machine

Peripheral grinding wheels and polishing wheels for double edger (pencil edge) machines

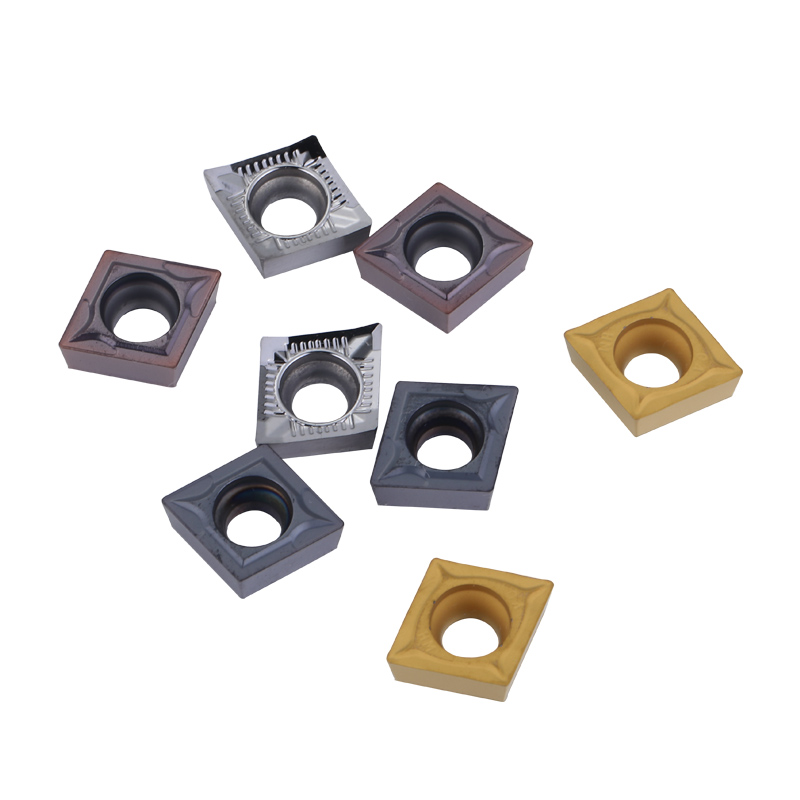

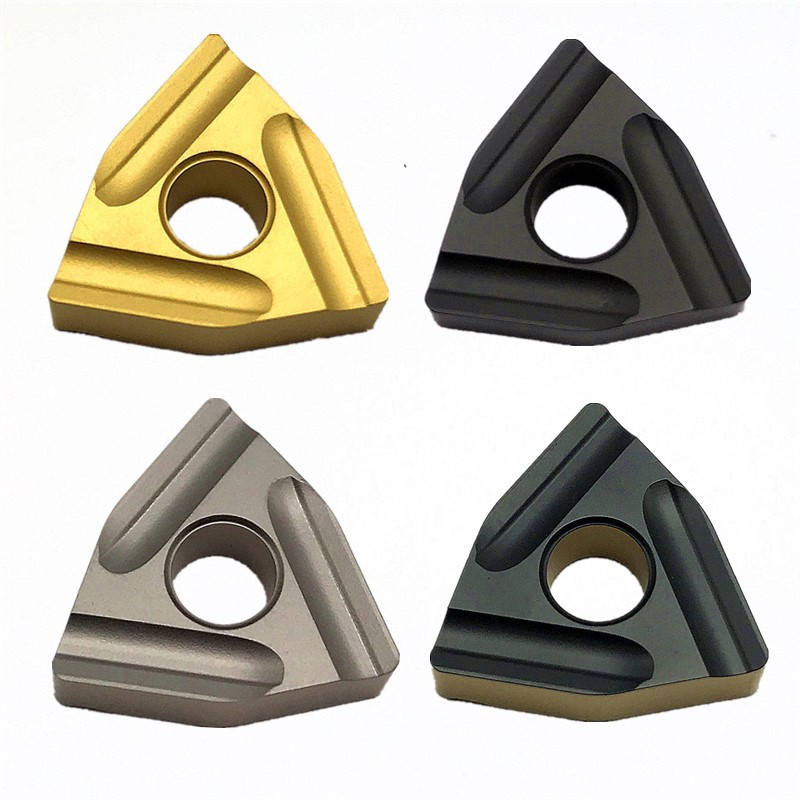

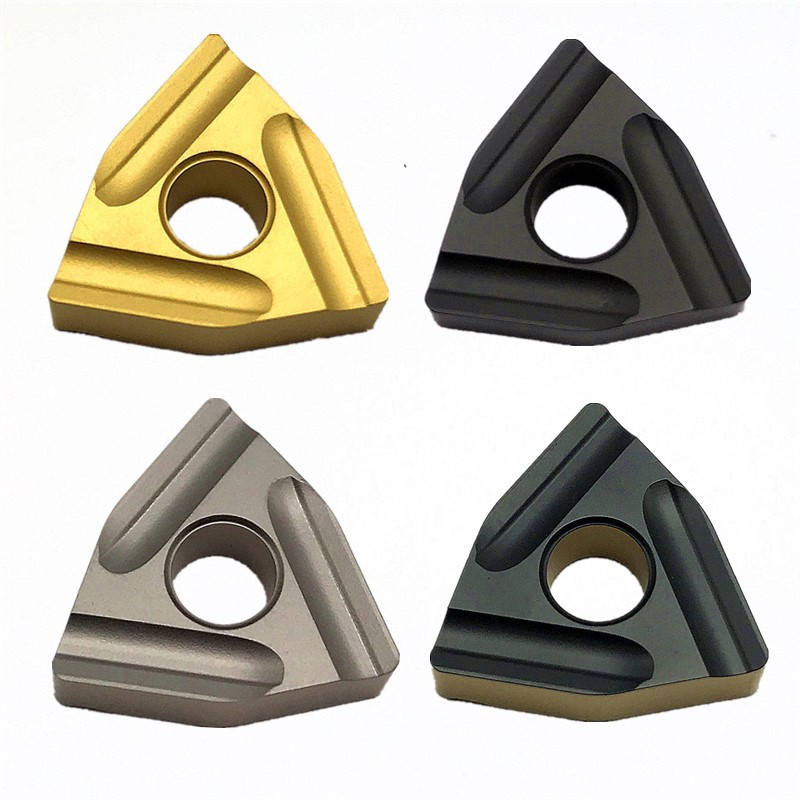

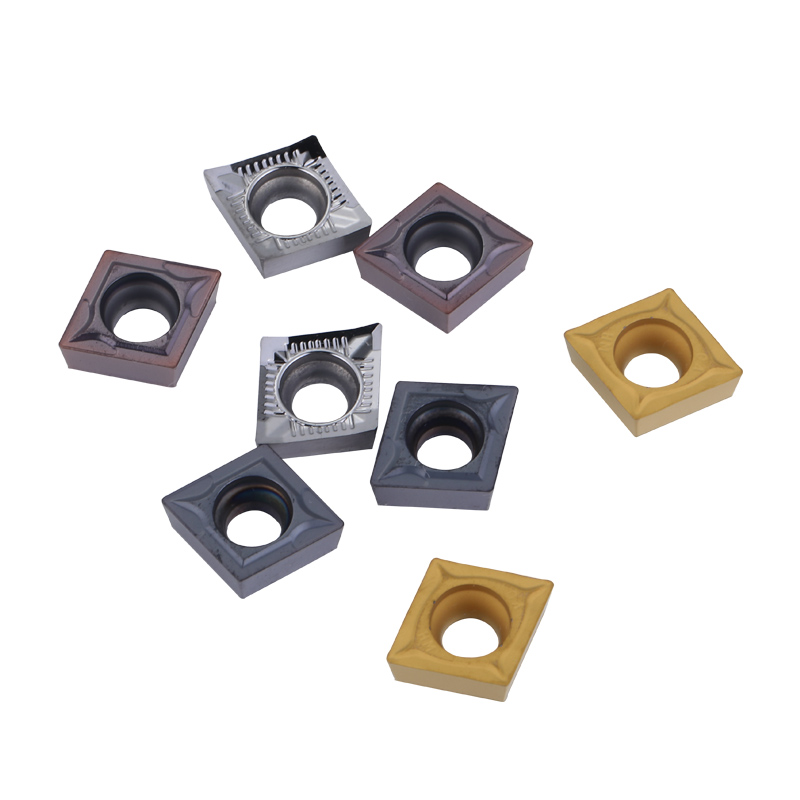

Carbide Turning Inserts

Fully Automatic Insert Peripheral Grinding Machine" is a specialized piece of equipment used in manufacturing for the precise grinding of inserts.

Fully Automatic: This indicates that the machine operates without the need for manual intervention once it's set up and started. Fully automatic machines are often used in high-volume production environments where efficiency and consistency are crucial.

Insert: In manufacturing, an insert usually refers to a small cutting tool or a component that is inserted into a larger tool or machine for specific functions, such as cutting, milling, or drilling. Inserts are commonly made from hard materials like carbide and are used in machining operations for durability and precision.

Peripheral Grinding: Peripheral grinding involves grinding the outer edge or periphery of a workpiece or component. In the context of this machine, it likely refers to the process of grinding the edges of inserts to achieve precise dimensions, shapes, and surface finishes.

Grinding Machine: This is a machine tool used for grinding, which is a machining process that uses an abrasive wheel as the cutting tool to remove material from a workpiece. Grinding machines come in various types and configurations, each designed for specific applications and materials.

Fully Automatic Insert Peripheral Grinding Machine would be designed to automatically grind the periphery of inserts to precise specifications without requiring manual intervention, making it suitable for high-volume manufacturing environments where consistency and efficiency are paramount.

CNC periphery grinding machine for carbide turning inserts is a highly specialized piece of equipment used in manufacturing processes, particularly in the production of carbide cutting inserts used in turning operations on lathes.

CNC: CNC stands for Computer Numerical Control. This indicates that the machine is controlled by a computer, allowing for precise and automated control of the grinding process. CNC machines are highly versatile and can execute complex machining operations with high accuracy.

Periphery Grinding: As mentioned earlier, periphery grinding involves grinding the outer edges or periphery of a workpiece. In the context of carbide turning inserts, periphery grinding is essential for achieving precise dimensions and shapes on the cutting edges of the inserts. This is crucial for ensuring the inserts perform optimally during machining operations.

Carbide Turning Inserts: Carbide turning inserts are cutting tools used in turning operations on lathes. They are typically made of carbide, a hard and durable material that can withstand the high temperatures and forces generated during machining. These inserts are designed with specific geometries to facilitate efficient material removal and achieve desired surface finishes.

A CNC periphery grinding machine for carbide turning inserts would be specifically designed to automatically grind the periphery of carbide inserts to precise specifications. The CNC control allows for programmable parameters such as cutting speed, feed rate, and depth of cut, ensuring consistent and high-quality results across batches of inserts. This type of machine is essential in the production of cutting tools for metalworking industries, where accuracy and performance are critical.