Galvanometer laser stripping machine

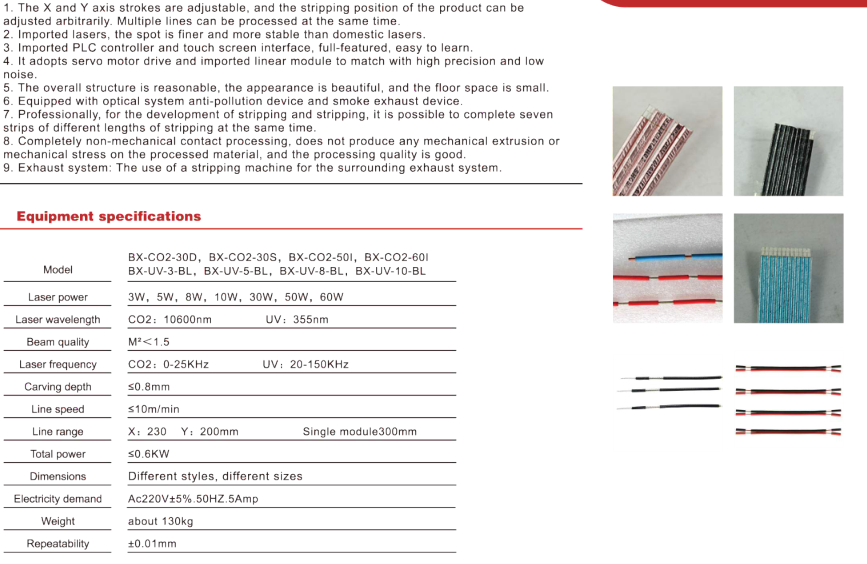

1. The X and Y axis strokes are adjustable, and the stripping position of the product can be adjusted arbitrarily. Multiple lines can be processed at the same time.

2. Imported lasers, the spot is finer and more stable than domestic lasers.

3. Imported PLC controller and touch screen interface, full-featured, easy to learn.

4. It adopts servo motor drive and imported linear module to match with high precision and low noise.

5. The overall structure is reasonable, the appearance is beautiful, and the floor space is small.

6. Equipped with optical system anti-pollution device and smoke exhaust device.

7. Professionally, for the development of stripping and stripping, it is possible to complete seven strips of different lengths of stripping at the same time.

8. Completely non-mechanical contact processing, does not produce any mechanical extrusion or mechanical stress on the processed material, and the processing quality is good.

9. Exhaust system: The use of a stripping machine for the surrounding exhaust system.