Grinding and deburring machine designed for the removal of slag from plasma and oxy-fuel cut parts, particularly for processing small parts. The machine is engineered for plate material processing, offering both flexibility and cost-effectiveness, and excels at edge rounding, with up to a 2mm radius.

Technical specification for the equipment:

| Technical Parameter | Details |

| Working width | ≤1350mm |

| Processing thickness | 0.5~80mm |

| Minimum processing size | 50mm × 50mm |

| Machine power | 56.75KW |

| Sand belt size | Φ 1910mm × 1350mm |

| Sand rolling brush size | Φ 300mm × 400mm |

| Delivery speed | 0.5~6m/min |

| Sand belt line speed | 12m/s |

| Rolling brush rotation speed | Adjustable frequency conversion of 500~1400r/min |

| Rolling brush public speed | 1~15r/min |

| Number of roller-brush planetary revolution shaft heads | 1 |

| Number of rolling-brush planetary rotation shaft heads | 8 |

| Machined thickness servo adjustment precision | 0.01mm |

| Rolling brush compensation servo adjustment precision | 0.01mm |

| Grinding consumables | Sand belt + rolling brush |

| Dust air volume | 5000m³/h |

| Unit contour size | Length 3250mm, Width 2300mm, Height 2150mm |

| Weight | Approximately 3.5T |

1350mm dry grinding and deburring machine is designed for effectively removing excess burrs and oxide layers from one side of materials. It also provides excellent surface finishing and edge rounding capabilities, achieving a radius of up to 2 mm. This machine is suitable for processing a variety of materials, including stainless steel, steel, aluminum, and non-ferrous parts.

Features and Functions of the Machine:

Wide Range of Materials: Suitable for processing stainless steel, steel, aluminum, and non-ferrous metals.

Simultaneous Multi-Material Processing: Capable of processing materials of different thicknesses at the same time (with E-units).

Individually Adjustable Processing Parameters: Customizable settings for optimal results.

Uniform Processing: Thoughtful design of the rotary heads ensures even processing across the entire working width.

Maximum Tool Contact: Ensures perfect edge rounding with up to a 2mm radius.

Efficient Small Part Processing: Capable of handling parts as small as 50x50mm, regardless of their geometry.

Fixed Worktable: Constant table height for ergonomic work.

User-Friendly Interface: Intuitive operation via a touch panel.

Energy Efficiency: Individual processing units can be switched on or off for flexible and energy-efficient operations.

Fast Machine Setup: Automatic positioning of tool axes enables quick machine settings.

Program Memory: Automatically stores machine settings, ensuring consistent and reproducible processing results.

Quick Tool Change System: Minimizes setup time for increased efficiency.

Wide Tool Selection: A broad range of tools for maximum flexibility in processing.

Easy Maintenance: Optimal machine accessibility for cleaning and maintenance, with windowed machine doors for process monitoring.

Customization Options: Available features and options to meet specific customer requirements, including automation and production line integration.

P-Edition Features:

Reduced Tool Costs: Mechanical slag removal eliminates the need for expensive grinding.

Cool Grinding: Minimal heat transfer into the workpiece, preventing warping.

Soft Contact Rollers: Large, soft contact rollers compensate for warping and tolerance issues, ensuring a perfect edge rounding up to 2mm.

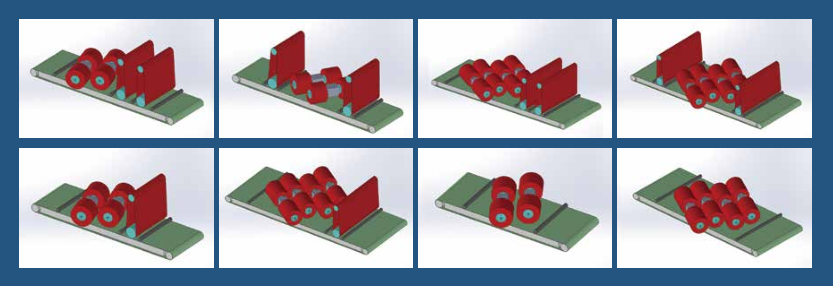

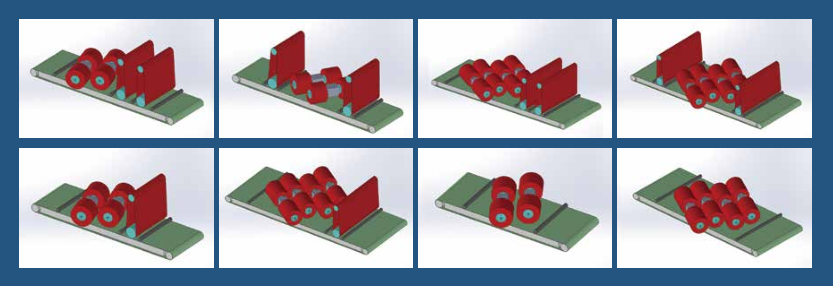

Available Configurations: Options include REE, DRE, REER, DREE configurations for different processing needs.

Efficient Small Part Processing: PowerGrip belts, magnetic tracks, or vacuum tables allow for the processing of very small parts.

Space-Saving Design: 30% less installation space required due to the compact design of the units.

Uniform Edge Rounding: Multiple brush heads ensure consistent edge rounding and multidirectional surface finishing.

This machine is ideal for deburring, edge rounding, slag removal, oxide layer removal, and surface finishing. It processes plasma and flame-cut parts made of stainless steel, steel, aluminum, and other materials.