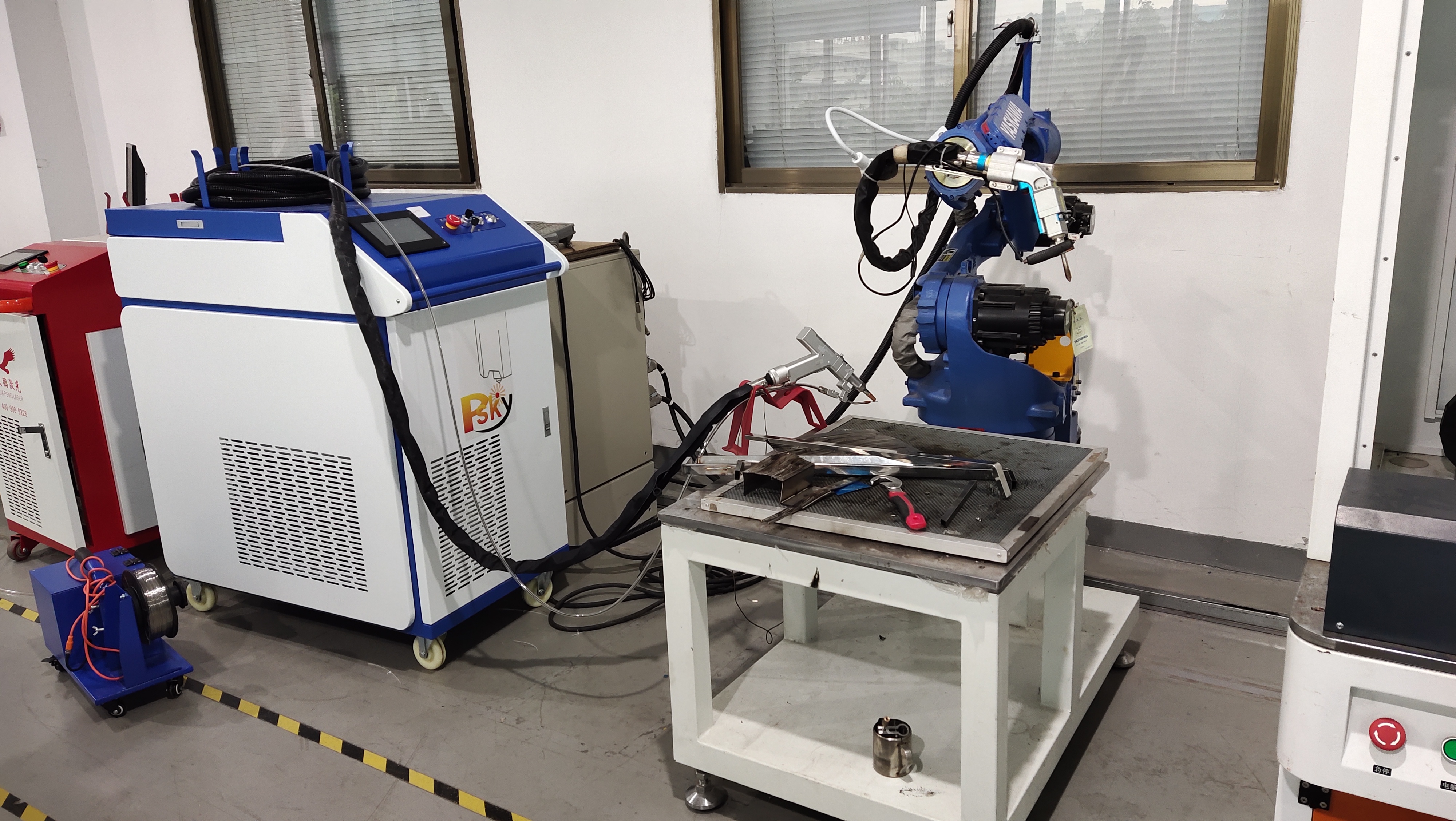

DPH-1000/1500/2000-SC handheld laser welding machine

Hand-held laser welding machine with raycus continuous fiber laser and suplaser hand-held welding head

The light of the laser is transmitted by the optical fiber line to the hand-held laser welding gun and emits the laser. The laser becomes heat and is transferred to the surface of the carrying object for melting or the welding wire is melted. The welding bead is formed by the auxiliary inert gas protection, so that the two objects are firmly bonded together. .

(The chiller water flows to the laser and the hand-held welding head to cool down and maintain the temperature, thereby protecting important components.)

QI LIN double pendulum handheld welding torch

Products Show

Digital display smart cutting head, dual pendulum handheld welding gun, robot, dual-axis swing welding platform, dual pendulum welding head, laser accessories, current location: Home: Products: dual pendulum handheld welding torch

Dual pendulum handheld welding torch

Double pendulum handheld welding torch Double pendulum handheld welding torch

Product detailsTechnical parametersRelated products

Hand-held welding head technical parameters

1. Interface type-QBH 2. Power range-2000W 3. Laser wavelength-1064-1080 4, Spot adjustment-(0-5) MM 5, Collimation focal length/focus focal length-120/150 6, Protective lens-D20X2 7 , Cooling method-water cooling 8, handle weight -1KG 9, mode selection-point-line-circle

Protective function

1. Laser head protection: When the laser head has an (E) signal or there is no data output, the system detects a motor failure, the laser head status light goes out, and the system stops sending light signals. The torch status can be lit, but the trigger is invalid.

2. On-state protection: The on-state signal is controlled by an independent 24V voltage. When an interference signal or a non-self-owned 24V voltage is received, the state is off, and the system stops sending light signals. The torch status can be lit, but the trigger is invalid.

3. Welding gun status protection: When the welding gun receives the conduction state and the laser head state are all normal, that is, the conduction signal is independent of 24V and the laser head is independent of 15V, and the system sends out the optical signal normally. Press the trigger button to emit light

4. Trigger button protection: This button is equipped with multiple independent circuits, that is, when any protection function is interfered or malfunctioned, releasing the trigger button can force the system to stop the connection with the laser, effectively preventing the laser from being emitted.

5. System leakage protection: The motherboard has added multiple isolation protection to prevent the chassis leakage, lightning and other factors from burning the motherboard or disturbing the motherboard.

6. Shell protection: The motherboard and driver are protected by a metal shell, which can better shield the outside world

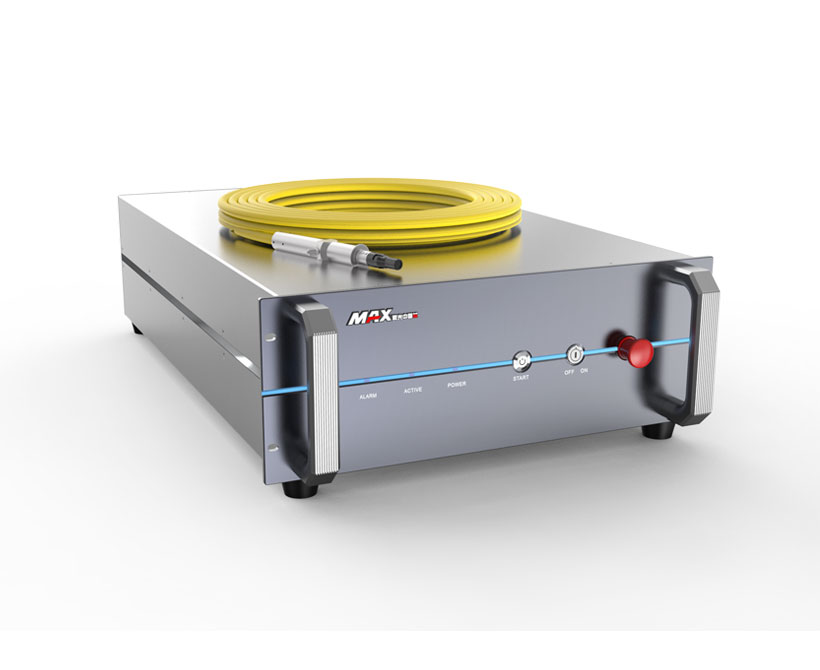

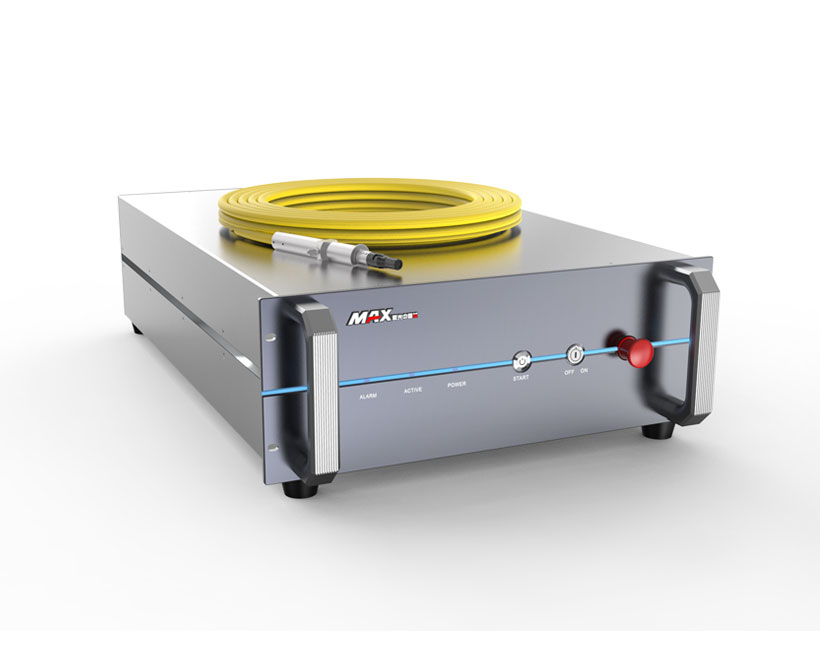

MFSC 700W-1500W single-mode continuous fiber laser adopts modular design, highly integrated system, maintenance-free, and high reliability. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can be used with laser processing heads, galvanometers, etc. to integrate with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields.

Product Description

MFSC 700W-1500W single-mode continuous fiber laser adopts modular design, highly integrated system, maintenance-free, and high reliability. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can be used with laser processing heads, galvanometers, etc. to integrate with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields.

Product leaflet

Product Manual

Modular design, stable performance

The internal structure adopts the photoelectric module separation design, and the operating performance is more stable

Easy maintenance, reducing downtime

Optical modules, electrical modules, control units, and drive units can be directly replaced, upgraded, and maintained at the client

Can be customized to meet a variety of needs

Users can choose fibers with different core diameters according to different processing needs to meet differentiated processing needs

Even spot energy distribution, stable processing

Reduce welding spatter, thick plate cutting ability is more stable

Multi-scene, wide application

It can be used with laser processing heads, galvanometers, etc. for system integration with robots, machine tools, etc., for laser fine cutting, precision welding, and application in 3C, hardware, medical, automotive, aviation and other fields

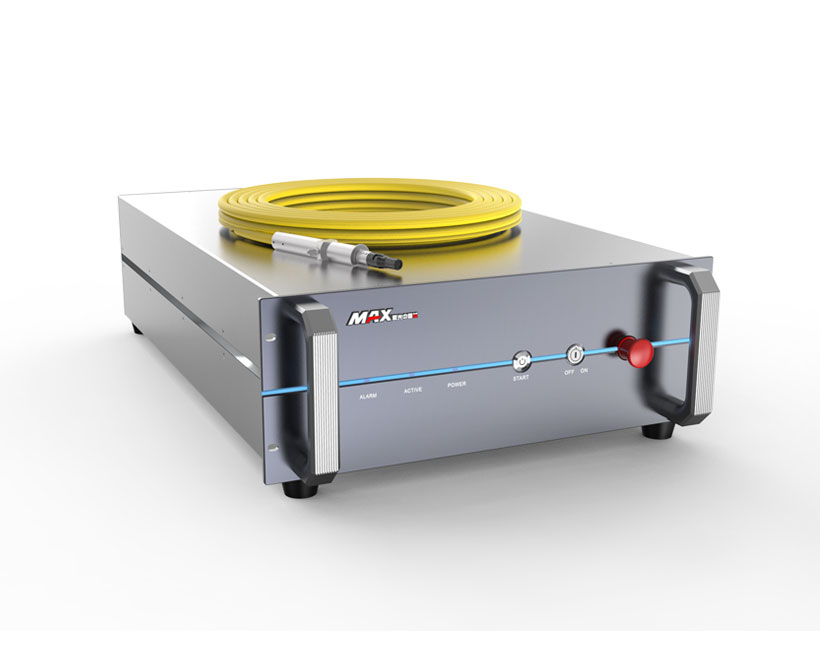

MFSC-2000W Single Module Continuous Fiber Laser

It can be quickly and conveniently integrated into machine tool equipment and automated production lines of large processing manufacturers.

Product Description

Chuangxin Laser's new generation single-module 2000W laser, this product integrates high power, lightweight size, humanized control, high-quality beam quality, and high light conversion efficiency. It can meet the requirements of precision processing. 3C product welding and high-reflection material cutting capabilities are significantly improved. It is suitable for remote processing. The laser cutting frequency is high and the cutting surface is smooth. It can be quickly and conveniently integrated into machine tools and large-scale processing manufacturers' automated production lines.

High power output, compact size

Combines high power, compact size, user-friendly control, high-quality beam quality, and high light conversion efficiency in one

Modular design, easier to maintain

Adopt photoelectric separation design, quickly replace the optical path or circuit module on site

Independent control to reduce downtime

Adopt single pump control technology, can realize independent control, quickly shut down a single abnormal pump source and still run

Intelligent monitoring, easy operation

Embedded with a new generation of intelligent software independently developed by Chuangxin Laser, real-time dynamic monitoring of various operating indicators of the laser

High integration and wide application

It can be quickly and easily integrated into machine tool equipment and automated production lines of large processing manufacturers