Handheld laser welding helps rail transit move towards a smart future

Preface: The stainless steel car body of rail cars not only has the characteristics of high strength, good durability, high environmental protection and high recyclability, but also has the advantages of good car body firmness, exquisite appearance, long service life and high welding efficiency. sought after.

Laser welding is a method of melting the materials to be connected to form a weld by focusing a high-energy laser beam on the surface of the part to be connected. There are many long straight welds in the manufacture of stainless steel car bodies for rail cars, and vehicle manufacturers in Japan, Germany, and China all have the capability of laser welding of stainless steel car bodies. However, the high cost, long cycle, poor accessibility, and poor flexibility of special-purpose laser welding equipment hinder the further development of laser welding technology in stainless steel car bodies. In recent years, with the emergence of hand-held laser welding equipment, it is possible to further apply laser welding technology for the manufacture of stainless steel car bodies.

1 Development of Handheld Laser Welding

From power input to real laser formation, it needs to go through three stages: pump source, gain medium, and resonator. The energy is pumped from the pump source (lamp, diode, radio frequency device, etc.) to the laser medium, the laser medium is stimulated to send laser radiation, the radiated laser light is amplified in the resonator, and finally high-power laser light is output through the optical path. According to different gain media, lasers can be divided into gas lasers, solid-state lasers, and liquid lasers (not used in industry).

Among them, the currently widely used solid-state laser medium is composed of synthetic single crystal yttrium aluminum garnet (YAG) or glass doped with optically active ions such as neodymium (Nd) or ytterbium (Yb). The function of the solid-state laser gain medium is to promote the maximum absorption of the laser light emission, while ensuring that the heat is consumed as efficiently as possible. Due to the different structures of the gain medium, solid-state lasers are classified into disk lasers, fiber lasers, and semiconductor lasers. The gain medium of traditional solid-state lasers is rod-shaped, the gain medium of disk lasers is thin and wide disk-shaped, and the gain material of fiber lasers is slender optical fibers.

The emergence of optical fiber transmission equipment solved the problem that the optical path changes according to the direction of use. The first generation of handheld laser welding equipment appeared. Although the first generation of handheld laser welding equipment can achieve welding within a certain range, the photoelectric conversion efficiency Low, large equipment volume (4~6 times the volume of ordinary argon arc welding equipment), small welding penetration, small weldable range, high equipment cost (more than 3 times the equipment cost of argon arc welding), which is similar to argon arc welding equipment. Compared with arc welding, it is mainly used in billboards and decorative parts with aesthetic requirements. There is no substitute for argon arc welding for structural connectors.

Fiber lasers have made great progress in recent years, and their main advantages are: high photoelectric conversion rate, fast heat dissipation, good flexibility, strong anti-interference ability, low cost, long life, adjustment-free, maintenance-free, high stability, small size, Hand-held laser welding equipment using fiber lasers has also gradually developed. Laser welding has high requirements on the assembly accuracy of the workpiece, and the welding seam is prone to defects. In order to solve this problem, the designers have developed a hand-held laser welding equipment with spot swing with reference to the special laser welding equipment. The laser is in the shape of "8" or "" O" type swing, which can reduce the accuracy of workpiece assembly and increase the welding penetration. After a series of optimization and improvement, the current common handheld laser welding equipment has a power of 0.5~1.5kW, and the size and weight of the equipment are comparable to those of argon arc welding machines, which can weld metal plates of 3mm and below. In order to solve the shortcomings of insufficient weld strength of laser welding structures, in recent years, equipment manufacturers have integrated automatic wire feeding devices on the basis of laser welding, and developed hand-held laser wire filling welding equipment that can automatically feed wires, which basically meets the requirements of thin metal plates below 4mm. It can basically replace and surpass argon arc welding, and realize high-speed, low heat input, small deformation, low-cost and environmentally friendly welding, and the manufacturing cost is lower than that of argon arc welding under the same conditions.

2 Features of hand-held laser welding

2.1 Advantages of hand-held laser welding

1) Hand-held laser welding has the characteristics of high efficiency, low heat input, low cost and environmental protection of laser welding. At the same time, because the front end of the welding torch is usually designed with a long guide nozzle, the tip of the guide nozzle can stick to the workpiece during the welding process and move along the shape of the workpiece. In the process of use, personnel do not need to overcome the gravity of the welding torch itself like manual arc welding, and it can be operated with one hand. Therefore, the skill level of the welder is relatively low. Usually, a welder only needs 5~7d from the beginning of learning to skilled use. , and under the same circumstances, skilled hand arc welders need to spend 30d or even longer.

2) For more complex workpieces, its efficiency is qualitatively improved compared with traditional hand arc welding. In terms of flexibility, the welding torch can be customized and can be adapted to welding in various narrow spaces, that is, where hand arc welding can be welded, and hand-held laser welding can also be completed.

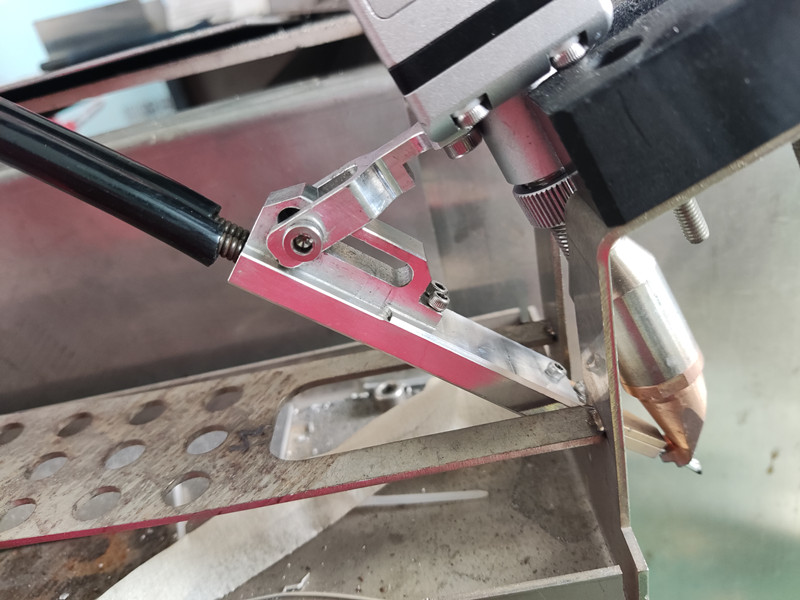

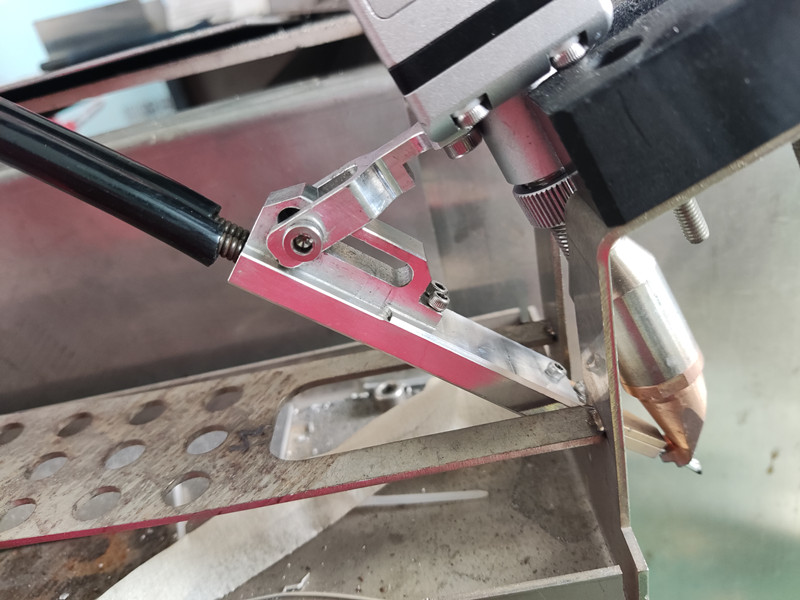

3) The laser welding seam is smooth and beautiful, and the size of the weld metal is small, which is suitable for parts with high appearance requirements. The common laser welding head form is shown in Figure 1. Usually, hand-held laser welding can be used for conventional joints of 3mm and below. Finish.

2.2 Disadvantages of hand-held laser welding

1) Since the laser may be dangerous to the eyes and skin whether it is direct or reflected, when welding aluminum, aluminum alloy, copper, gold, silver and other highly reflective materials, a large part of the laser will be reflected by the material, and the laser belongs to invisible light. , attention should be paid to the reflection angle during operation, and cross-operation should be avoided in the process of using hand-held laser welding. At the same time, in order to prevent personal injury caused by laser reflection, scattering and diffuse scattering in the area of the laser equipment, isolation protection facilities should be set up, and operators should wear protective clothing. Laser glasses.

2) For common laser welding seams, the gap after assembly of the workpiece is required to be ≤ 0.1mm. In order to reduce the assembly accuracy requirements and reduce the manufacturing cost of accessories, hand-held wire filler laser welding and oscillating hand-held laser welding equipment can be used. The equipment capacity and product conditions are tested with different gaps and finally meet the needs of use.

3) The hand-held laser welding uses the equipment optical fiber to transmit the laser light. When the bending radius of the equipment transmission line is too small, the optical fiber will be damaged. Therefore, the bending angle should be avoided as much as possible during the welding process. Usually, the length of a single continuous welding seam should be controlled within the range of personnel activities. For a long straight seam with a length of more than 2m, it can be considered to be carried out in sections, and a welding torch cable suspension device can be installed.

4) Manual welding is still used in hand-held laser welding, and long-term operation will cause fatigue. For long straight welds with good welding accessibility, special machines or automated equipment need to be considered for welding.

3 Application prospect of stainless steel car body

The stainless steel car body has the characteristics of strong corrosion resistance, good plasticity and toughness and no coating, and is favored by customers. Laser welding of stainless steel car body has the incomparable advantages of traditional welding. It has high welding strength, can effectively reduce defects, and has beautiful appearance, so it is highly respected.

The stainless steel car body of rail vehicles is usually composed of thin plates. The lightweight design of the stainless steel car body (see Figure 2) is made of thin-walled materials, with a plate thickness of 0.8~3mm, except that the plate thickness of the bearing part of the underframe structure exceeds 4mm. Among them, the thinnest corrugated plate at the top cover is only 0.8mm, and the steel material of the side wall and end wall plate required for the outer surface is usually 2mm, which are all within the range of plate thickness suitable for hand-held laser welding.

3.1 Application Prospect of Welding Seam Requirements for Aesthetics

The lap welding seam around the door frame and the side wall skin (see Figure 3), which is located at the entrance of the passenger compartment of the vehicle body, the fillet weld between the end wall drainage and the end wall skin (see Figure 4), the end wrapping and the The lap welding seam of the side wall skin (see Figure 5) is located on the visible surface of the platform passengers, and has high requirements for the aesthetics of the welding seam. The heat input will cause deformation of the outer surface, but in order to ensure that the vehicle runs for a long time without corrosion and structural needs, the current conventional solution is the method of argon arc welding section welding + glue treatment, and the argon arc welding seam is fish scale. , The uneven position of the welding seam sometimes occurs, the welding seam joint is pitted or convex, unsightly, the operation of gluing the end welding gap is cumbersome, the thickness of the glue seam is small, it is easy to age and fall off, and the maintenance cost is high.

For the welds in the above positions, the position gap of the weld joints can usually be controlled within 0.1mm. The use of hand-held laser welding can completely replace the method of argon arc welding + gluing, greatly reducing the manufacturing cost and improving the efficiency. Straight and even, no grinding required, which can improve customer satisfaction.

3.2 Application prospect of large deformation weld

The lap weld between the clapboard and the curved beam above the top cover, and the fillet weld between the clapboard and the bottom plate (see Figure 6), each with a length of about 3m, when using hand arc welding, the heat input is large, even if segmented Jump welding, the deformation after welding is still large, the deformation of the bottom plate is more than 5mm, and the deformation of the partition plate is more than 10mm, which requires a lot of manpower and material resources to adjust. Using hand-held laser welding, the welding heat input is greatly reduced, and the welding speed can be increased by 3 times. The above can greatly reduce the work of subsequent adjustment and shape correction. At the same time, the welding seam is beautiful in shape, and the joints are less defective, which can reduce the joint grinding, thereby reducing the cost and improving the efficiency.