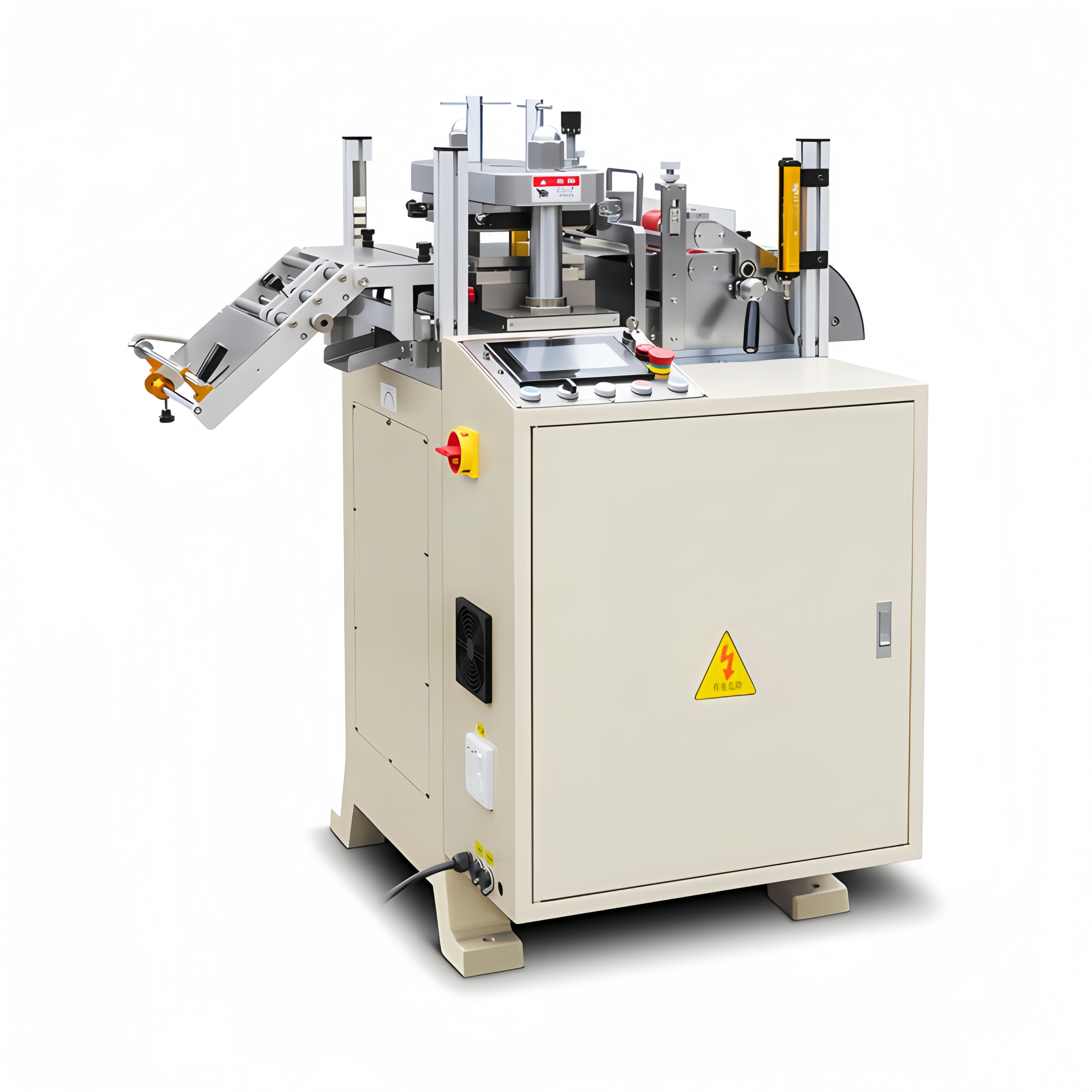

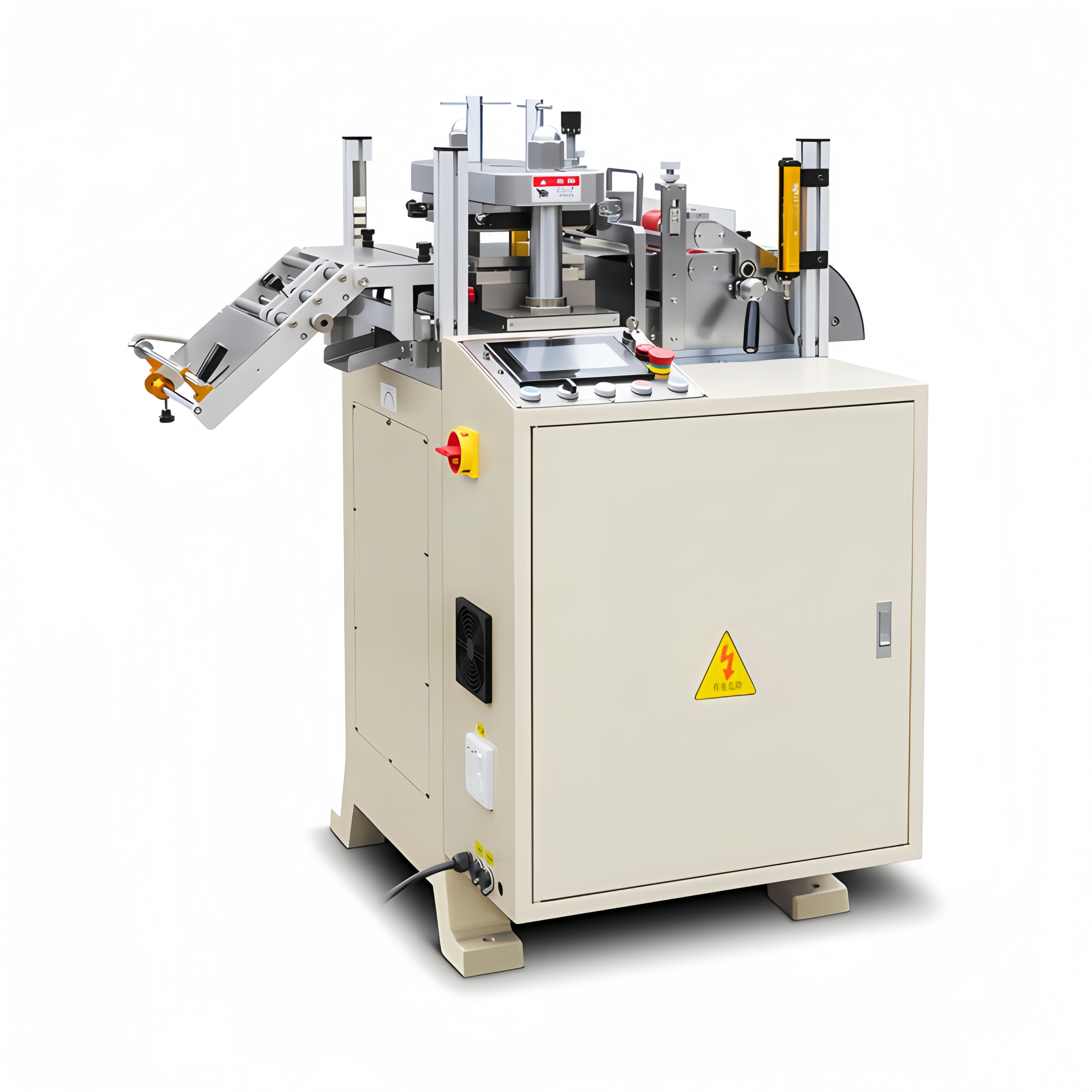

A high-speed flatbed die cutting machine with hydraulic capabilities for cutting EMI shielding materials, such as copper foil, is designed for precision and efficiency in industrial settings.

Key Features:

Hydraulic Press System: Provides consistent pressure and ensures precise cutting of copper foil and other EMI shielding materials.

High-Speed Operation: Capable of high-speed cutting to meet the demands of large production volumes.

Flatbed Design: Offers a stable cutting platform, ideal for handling flat materials like copper foil.

Precision Cutting: Equipped with high-precision die cutting tools to ensure clean and accurate cuts.

Versatility: Capable of cutting various thicknesses and types of EMI shielding materials.

Automatic Feeding and Stacking: Often includes automated systems for feeding and stacking, increasing productivity and reducing manual handling.

Adjustable Cutting Pressure: Allows for customization of cutting pressure based on material thickness and type.

User-Friendly Controls: Typically features an advanced control panel for easy setup and operation.

Specifications:

Cutting Area: Depends on the machine model, but often includes a large flatbed to accommodate various sheet sizes.

Pressure Capacity: Hydraulic systems typically provide a range of pressure settings, which could be in the range of several tons.

Speed: High-speed operation is essential for efficient production; specific speeds can vary by model.

Material Thickness Range: Machines can handle different thicknesses of copper foil and EMI materials.

Die Size: Customizable to fit various die sizes for different cutting needs.

Applications:

EMI Shielding: Effective for producing components used in shielding electronic devices from electromagnetic interference.

Copper Foil Cutting: Used for precision cutting of copper foil in various applications, including electronics and electrical components.