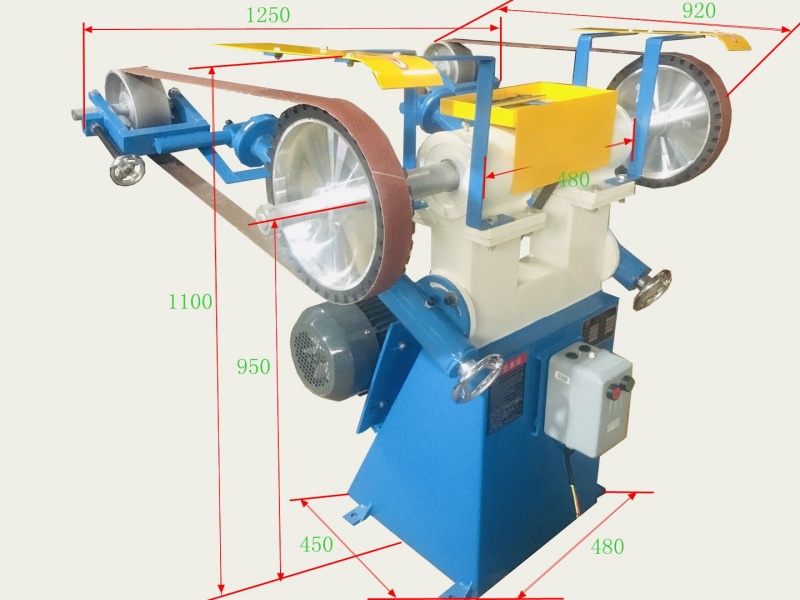

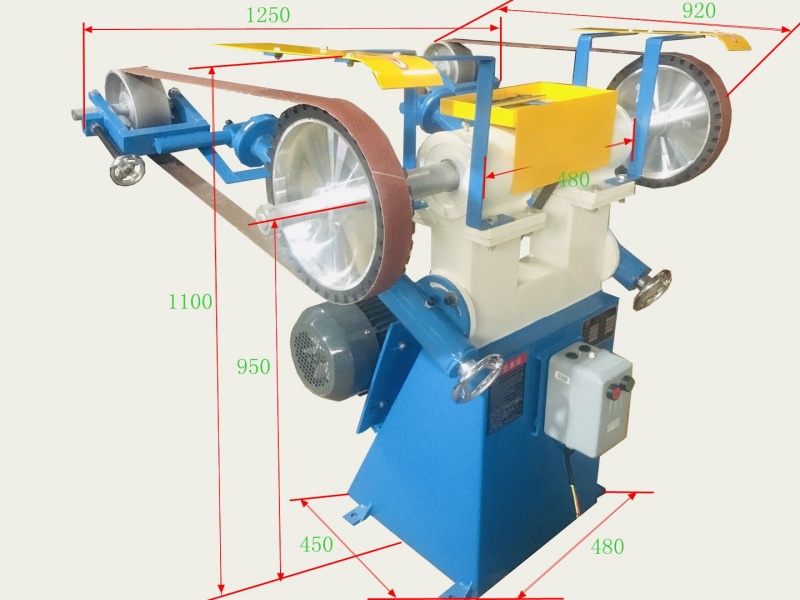

Industrial Dual-Station Belt Grinding & Polishing Machine

The Industrial Dual-Station Belt Grinding and Polishing Machine is a versatile surface finishing system designed for high-efficiency metal grinding, deburring, edge rounding, and polishing applications. Each side of the machine is equipped with an independent workstation, allowing the operator to mount either an abrasive belt or a polishing wheel — enabling true dual-purpose capability for rough grinding and fine finishing within one machine.

Key Features

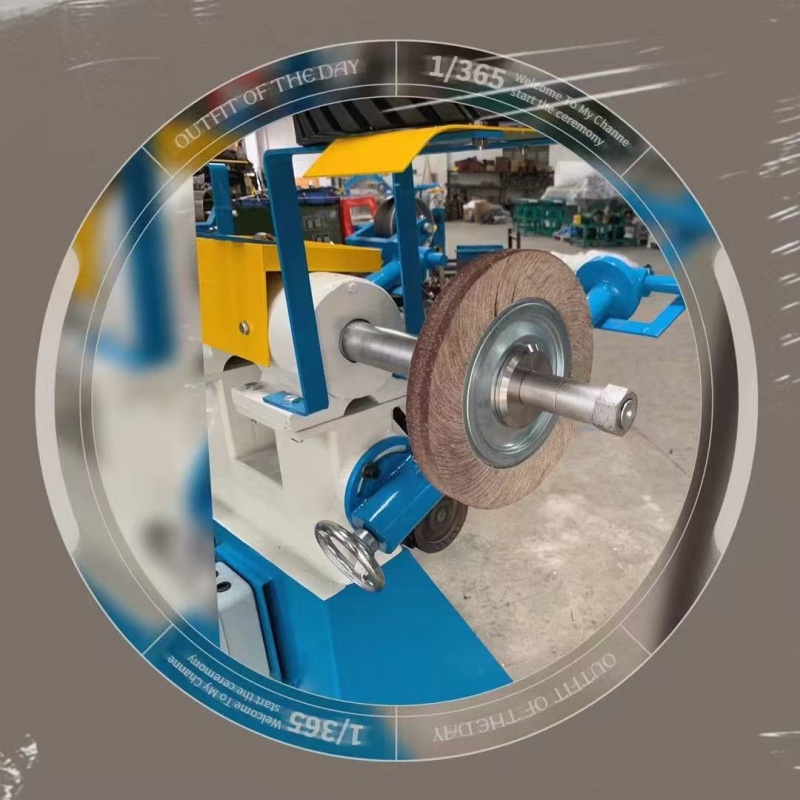

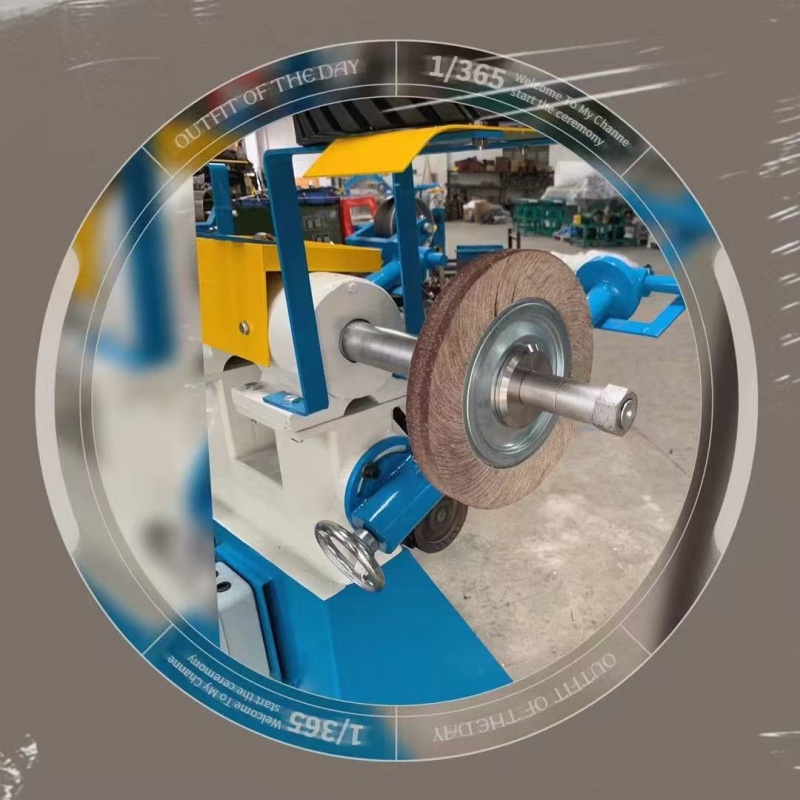

1. Dual-Purpose Design (Belt + Wheel Compatible)

Each workstation can be configured with:

Abrasive sanding belts for stock removal, weld grinding, edge deburring, or oxide removal.

Polishing wheels, flap wheels, cloth buffing wheels, or contact wheels for final finishing, edge smoothing, or mirror polishing.

This configuration allows operators to complete rough grinding and fine polishing operations on the same equipment, improving efficiency and reducing floor space.

2. Two Independent Workstations

The machine is equipped with left and right working heads, which can operate independently or simultaneously.

Operators can:

Mount belts on both sides,

Mount polishing wheels on both sides, or

Use mixed configuration (belt on one side, wheel on the other).

The dual-station layout supports multi-operator use and increases throughput for workshop and production environments.

3. Heavy-Duty Industrial Construction

The base frame and grinding arms are fabricated from reinforced steel to ensure:

Rigidity and vibration-free operation,

Stable grinding pressure,

Long service life even under continuous industrial workloads.

Designed for metal fabrication shops, stamping plants, welding factories, and polishing workshops.

4. Variable Speed Drive (optional)

Equipped with multi-speed pulley drive or VFD inverter control to adjust belt or wheel speed depending on:

Material type (aluminum, stainless steel, mild steel, copper),

Finishing stage (rough grinding vs fine polishing),

Heat sensitivity and dust requirements.

5. Dust Collection Enclosure and Safety Guarding

Each workstation is fitted with:

An enclosed grinding hood to contain sparks and metal dust,

An extraction port for connection to a central dust collector or independent vacuum system.

This ensures a cleaner working environment and reduces airborne contamination hazards.

6. Easy Belt Tracking and Quick Change System

A precision belt tensioning and tracking adjustment system allows:

Fast abrasive belt replacement,

Stable belt alignment at high speed,

Reduced maintenance downtime.

Operators can change belts or wheels within seconds to suit different process requirements.

Application Range

This machine is widely used for metal finishing tasks including:

Weld seam removal

Edge deburring and rounding

Oxide scale removal after laser cutting

Pre-paint / pre-plating surface conditioning

Stainless steel surface finishing

Aluminum polishing

Tool and fabrication part grinding

Fine polishing for decorative components

Suitable for sheet metal parts, hardware accessories, automotive components, stainless steel panels, aluminum frames, stamping parts, and general fabrication.

Advantages

✔ One machine performs grinding + polishing

✔ Two work zones improve productivity and flexibility

✔ Dust enclosure increases safety and cleanliness

✔ Variable speed adaptation enables precise finishing

✔ Modular belt/wheel mounting extends usability

✔ Industrial-grade stability for long-term operation

Typical Technical Specifications (customizable)

Motor Power: 1.5–3.0 kW per station

Belt Size: 50 × (1600–2100) mm or 2" × 72"/82" equivalents

Wheel Diameter: 150–250 mm, depending on finishing requirement

Speed Control: Multi-speed / inverter controlled

Dust Outlet: φ75–100 mm extraction port per station

Body Material: Welded steel frame with powder coating