Laser Cutter Slat Cleaner - 1600W Laser Table Slat Cleaner and Slag Remover

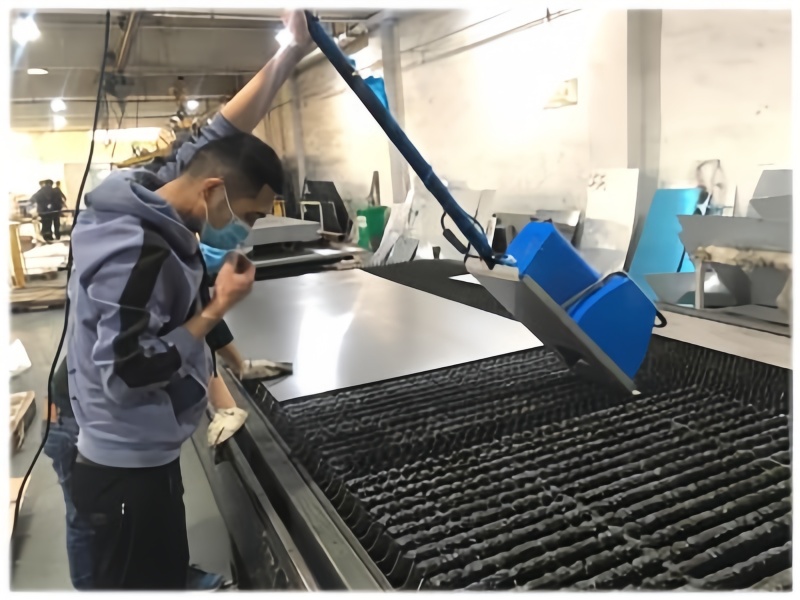

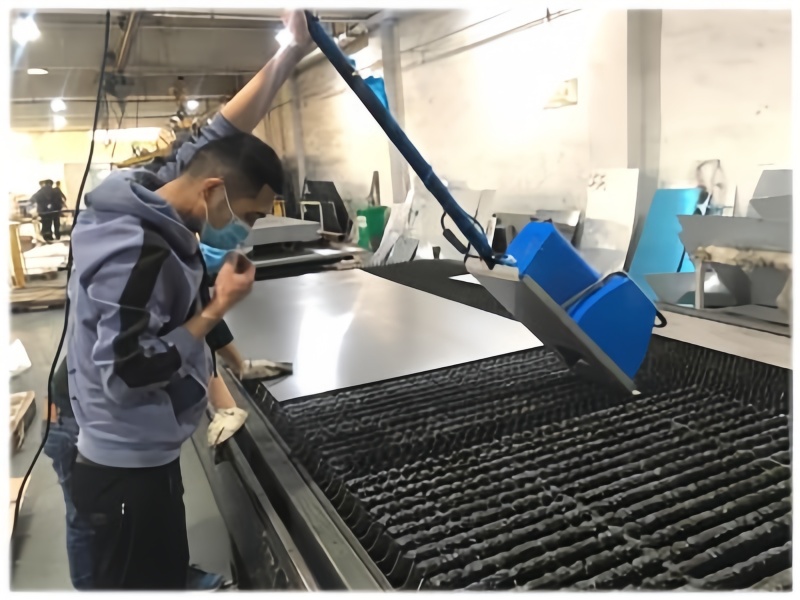

The 1600W Laser Cutter Slat Cleaner is a powerful and efficient tool designed for cleaning and removing slag, debris, and other residues from slats and slat beds of laser cutting machines and plasma cutting tables. This electric-powered slag remover helps to maintain laser and plasma cutting machines by keeping slats free from the buildup of metal slag, ensuring the optimal performance and longevity of your equipment.

Key Features:

High-Powered Cleaning:

1600W Power ensures quick and effective slag removal from the slats of laser cutting tables.

Suitable for laser cutters with power up to 6KW, helping to maintain a clean surface for precise cutting.

Compact and Portable Design:

Lightweight and portable, designed for easy maneuverability in workshops and production environments.

Comes with a handheld handle for convenient use and control, reducing operator fatigue during extended cleaning sessions.

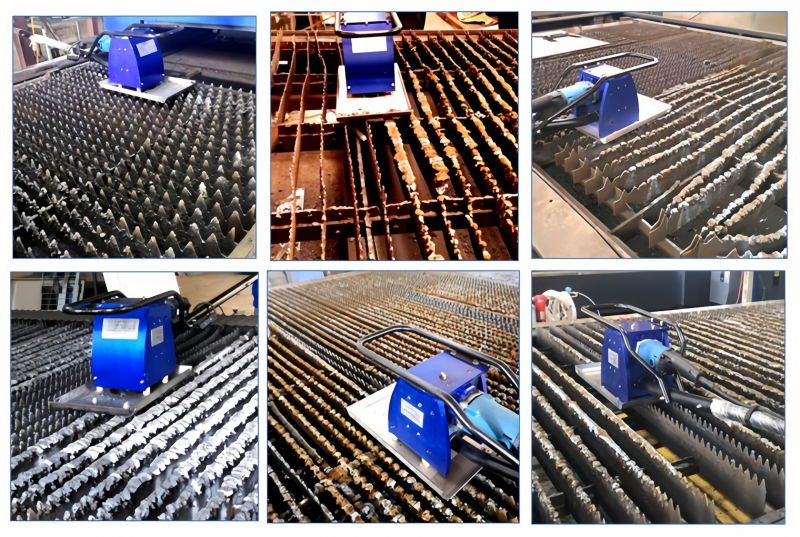

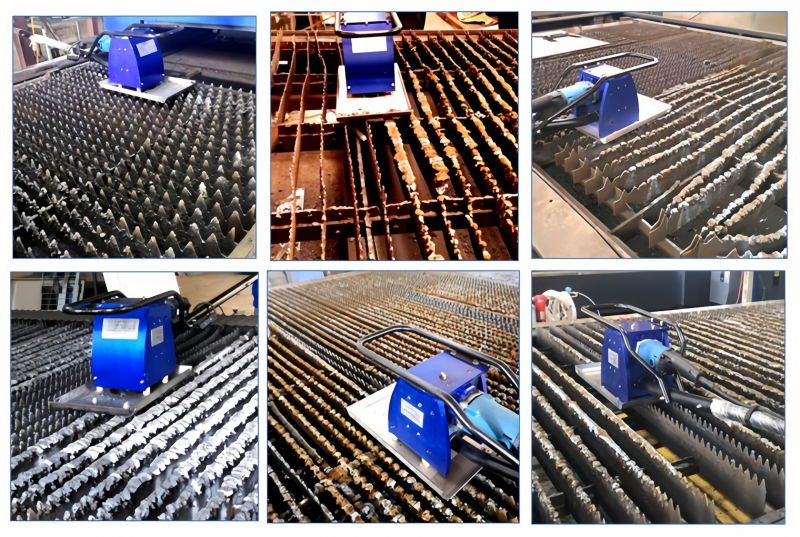

Efficient Slag Removal:

Specially designed for removing slag, metal debris, and residues from laser cutting tables and slats, ensuring smooth and clean surfaces for further use.

Ideal for CNC laser cutters, plasma cutters, and flame cutting machines.

Durable Construction:

Made with high-strength alloy steel and stainless steel components to withstand heavy-duty industrial use.

High wear resistance and heat resistance, ensuring long-lasting performance without damage or wear.

Adjustable and User-Friendly:

Safe Operation:

Efficient Waste Collection:

Specifications

| Model | STR-C1000 | STR-C1600 | STR-C2300 |

| Voltage | 220V/380V | 220V | 220V |

| Power | 1020W/1000W | 1600W | 2300W |

| Frequency | 50Hz | 50Hz | 50Hz |

| Laser Power Range | ≤6kW | - | - |

| Max Slag Width | ≤25mm | ≤25mm | ≤25mm |

| Slat Thickness | 3-5mm | 3-5mm | 3-8mm |

| Min Slat Spacing | 40mm | 40mm | 30mm |

| Continuous Work | 1 hour | 1 hour | 1 hour |

Applications:

Laser Cutting Machines: Efficiently cleans slag and residues from slats and cutting beds of laser cutters, ensuring optimal cutting performance.

Metal Fabrication: Ideal for the cleaning of slats used in CNC laser cutting, plasma cutting, and flame cutting.

Maintenance: A valuable tool for regular maintenance to prevent slag buildup, extend the life of cutting equipment, and improve cutting accuracy.

Slag Removal for Steel & Metal: Effective for removing steel slag, stainless steel slag, and other residues left after the cutting process.

Slat Cleaner for High-Power Lasers: Compatible with CNC laser cutting machines with power ratings up to 10kW.

Why Choose the Laser Slat Cleaner?

Cost-effective Maintenance: Regular use of this machine helps to maintain the quality of the laser cutting slats, reducing downtime and repair costs.

Increased Productivity: By keeping slats free from debris, the laser cutter can work more efficiently, improving overall productivity in the workshop.

Long-Term Durability: Built with high-quality materials to withstand rigorous industrial use, ensuring long-term service life.

User-Friendly: Easy to use with minimal training required, making it suitable for various operators in manufacturing environments.