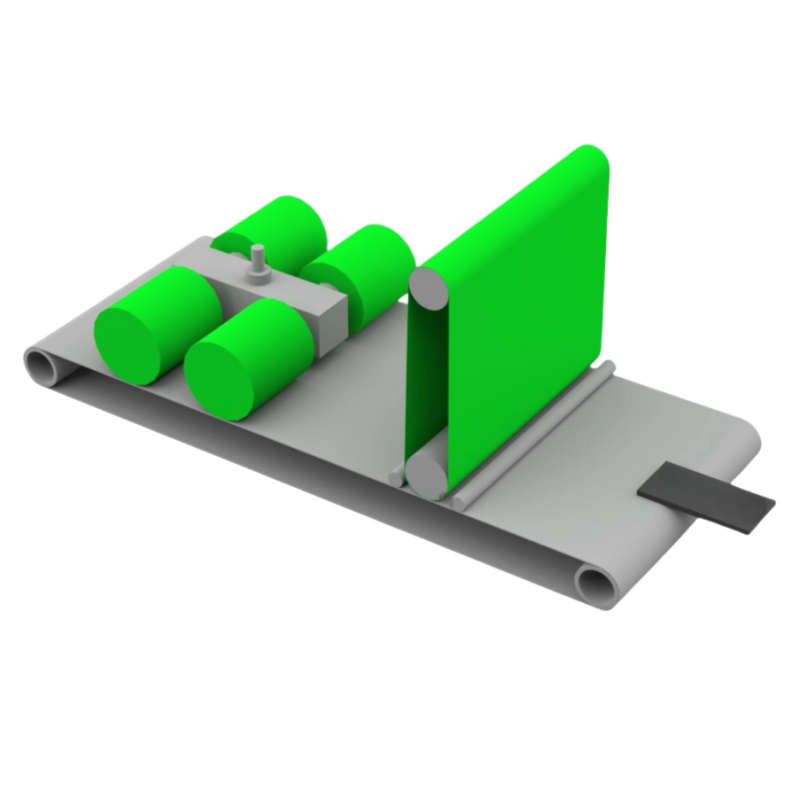

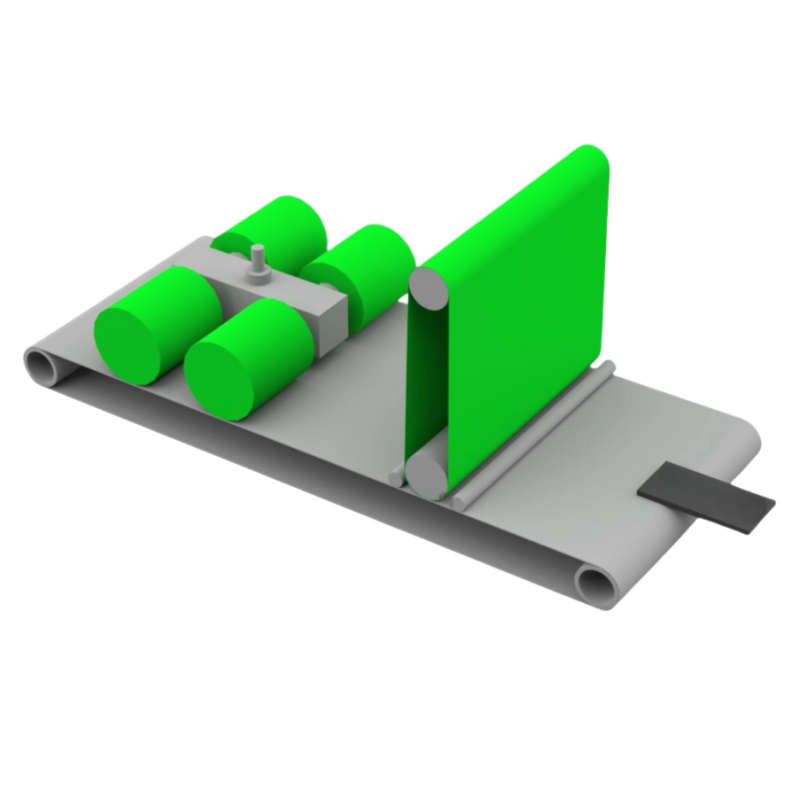

MSP-L800 Dry-Type Deburring and Sanding Machine

Product Name:

800mm Automatic Sheet Metal Wide Belt Sanding, Grinding, Deburring, Chamfering & Flat Polishing Machine

Product Overview:

This 800mm wide belt sanding machine is an advanced automatic solution for sheet metal surface finishing. Designed for high-precision metal processing, it integrates multiple operations including sanding, grinding, deburring, chamfering, and flat polishing into a single machine, improving efficiency and ensuring consistent surface quality.

Key Features:

Automatic Operation:

Wide Belt Sanding & Grinding:

Deburring & Chamfering:

Precisely removes burrs and sharp edges after cutting, punching, or laser processing.

Creates smooth, rounded edges for safety and better aesthetics.

Flat Polishing:

Durable Construction:

Versatile Material Handling:

Suitable for stainless steel, aluminum, galvanized sheets, and other metals.

Ideal for automotive parts, metal furniture, kitchenware, and industrial components.

Applications:

Metal fabrication shops

Automotive and machinery components finishing

Stainless steel and aluminum panel polishing

Workshop automation for deburring and edge finishing

Advantages:

Combines multiple processes into one machine, reducing production time.

Consistent and precise surface quality.

Easy to operate and maintain.

Enhances workplace safety by automating deburring and edge finishing.

Technical Specifications (Typical):

Working Width: 800mm

Main Motor Power: 11–15 kW (depending on configuration)

Belt Speed: Adjustable (5–20 m/min)

Air Pressure: 0.55 MPa (if pneumatic functions included)

Dimensions: Customizable depending on layout

Product Name:

Laser Cutting Aluminum Stainless Steel Sheet Metal Automatic Grinding, Polishing, Deburring & Sanding Machine

Overview:

This automatic machine is specially designed for sheet metal finishing after laser cutting. It combines multiple processes including grinding, polishing, deburring, and sanding, ensuring smooth edges, improved surface quality, and consistent finishing results for aluminum, stainless steel, and carbon steel sheets.

Key Features:

Multi-Process Integration – Grinding, sanding, deburring, and polishing in one machine.

Precision Finishing – Removes laser cutting burrs, oxide layers, and sharp edges.

Wide Material Compatibility – Suitable for aluminum, stainless steel, galvanized steel, and more.

Automatic Operation – Adjustable conveyor speed, PLC control, and user-friendly interface.

High Productivity – Reduces manual labor and ensures consistent finishing quality.

Edge Rounding & Surface Polishing – Improves coating adhesion and enhances product safety.

Applications:

Laser cut parts finishing

Aluminum and stainless steel sheet polishing

Metal furniture and kitchenware manufacturing

Automotive, aerospace, and electronics industries

Sheet metal fabrication workshops

Advantages:

Replaces manual grinding and polishing.

High efficiency for medium and large-scale production.

Uniform finishing across flat surfaces and edges.

Cost-effective and durable industrial solution.

| Feature Category | Specification Details | Notes |

| Model | MSP-L800 | Example model |

| Primary Process | Deburring, Edge Rounding, Oxide Removal |

|

| Compatible Materials | Mild Steel, Stainless Steel, Aluminum |

|

| Max. Material Thickness | 0 - 80 mm | Capacity for thin sheet to thick plate. |

| Max. Material Width | 800 mm | Standard processing width. |

| Min. Part Dimensions | 50 x 50 mm | Minimum processable part size. |

| Max. Material Weight | 350 kg | Maximum weight capacity per part. |

| Conveyor Speed | 0.6 - 4.0 m/min | Infinitely variable for process adjustment. |

| Abrasive System | Combination: Abrasive Belt + Flap Wheels | Belt for heavy burr removal, flaps for fine rounding. |

| Flap Wheels | 4 x Ø300 x 300 mm | Quantity, Diameter, and Length. |

| Tool Working Height | 120 mm |

|

| Power Consumption | 16.8 kW / 22.8 kW | Typical operating power / Peak power. |

| Holder/Conveyor System | Magnetic (Vacuum Optional) | Standard magnetic for ferrous metals; vacuum for alloys. |

| Min. Deduster Requirement | 3000 m³/h | Minimum air volume for effective dust extraction. |

| Compressed Air Requirement | 5.0 Bar (Min) | Required pressure for pneumatic systems and optional vacuum. |

| Machine Weight | ~2500 kg | Approximate net weight of the machine. |

| Control System | PLC (Programmable Logic Controller) | For automated, user-friendly operation and parameter storage. |

| Warranty | 1-2 Years | Varies by manufacturer. 16 |