H800C Metal Deburring and Edge Rounding Machine – Precision Edge Rounding for Laser, Shear & Punch Cut Parts

Key Features & Benefits:

✅ Edge Rounding up to 800mm Width – Ideal for removing light burrs and rounding sharp edges with a working width of up to 800mm.

✅ High-Performance Edge Rounding – Effectively rounds both external and internal contours of stainless steel, steel, and aluminum parts cut by laser, shear, or punching machines.

✅ Small Parts Capability – Handles metal parts of various dimensions, including small components as little as 50x50mm, ensuring smooth and burr-free edges.

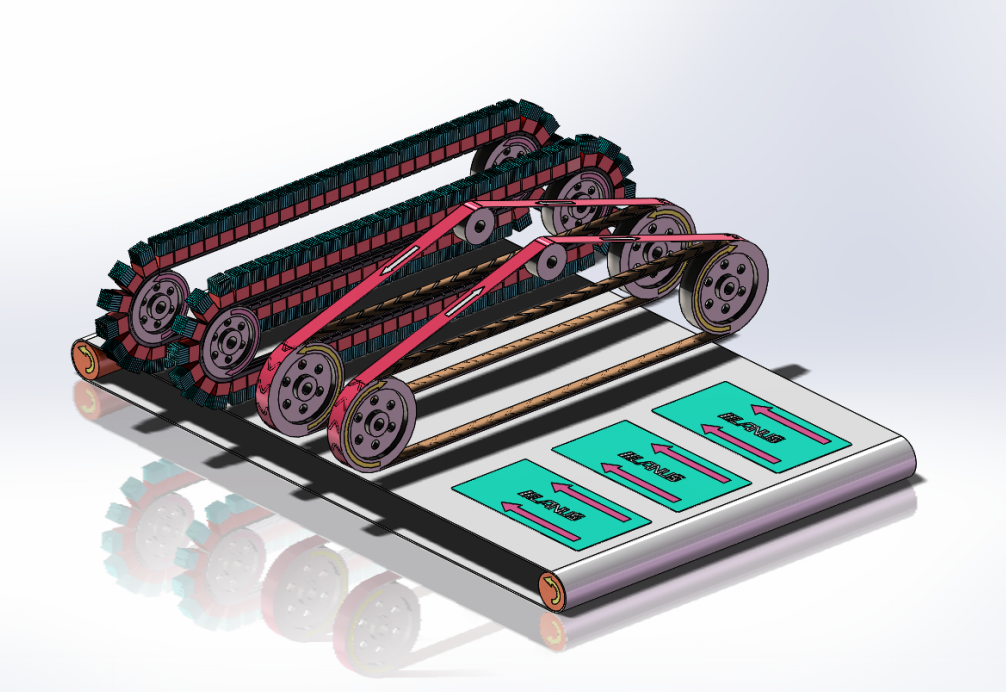

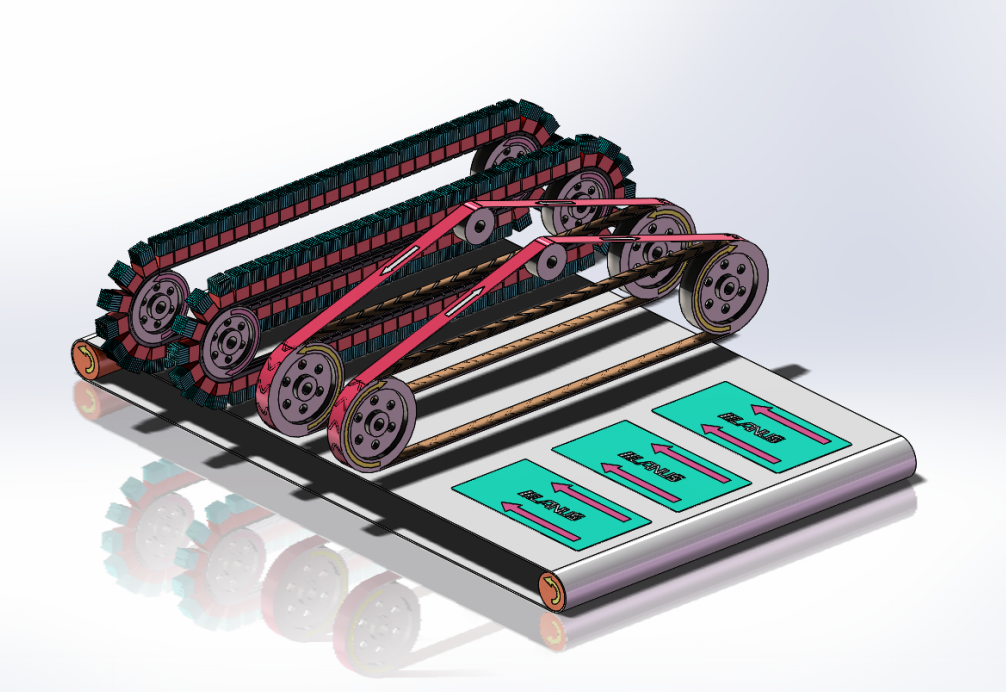

✅ Double Cross-Belt Deburring System –

Two counter-rotating abrasive cross belts work in opposite directions, ensuring complete edge rounding in every corner of the part.

Leaves clean, soft, and burr-free edges on the entire surface, enhancing safety and quality.

✅ Perfect Linear Surface Finishing – Delivers a uniform, high-quality finish, ensuring a smooth and aesthetically pleasing result on all processed parts.

✅ Plastic Protection Deburring – Maintains original finishing on parts with protective plastic foil, ensuring deburring focuses solely on the edges.

✅ Parts Return System for Productivity Boost –

H800C Metal Deburring and Edge Rounding Machine:

| Parameter | Specification |

| Model | H800C Metal Deburring & Edge Rounding Machine |

| Working Capacity (mm) | 1100 x 500 |

| Processing Thickness (mm) | 0.6 – 3.2 |

| Feeding Speed (m/min) | 2 – 8 |

| Cross Belt Speed (m/s) | Up to 3.26 |

| Total Power (kW) | 22 |

| Machine Dimensions (mm) | 2230 x 1510 x 2040 |

| Weight (kg) | 1350 |

| Abrasive Cross Belts | 2 counter-rotating belts |

| Minimum Part Size (mm) | 50 x 50 |

| Edge Rounding Radius | Strong edge rounding on parts |

| Plastic Protection Deburring | Yes |

| Parts Return System | Yes (for small parts & double-sided operation) |

| Applications | Laser-cut, plasma-cut, punched, and sheared parts |

Applications:

✔ Laser-Cut Part Deburring & Edge Rounding – Sharp edges on laser-cut stainless steel or steel parts are efficiently removed.

✔ Punching Machine Part Finishing – Smooths burrs and sharp edges from punched parts.

✔ Plasma and Shear Cut Parts Processing – Provides uniform edge rounding and slag removal for a perfect finish.

✔ Small & Large Part Processing – Capable of handling tiny parts (50x50mm) up to full-size sheets (800mm width).