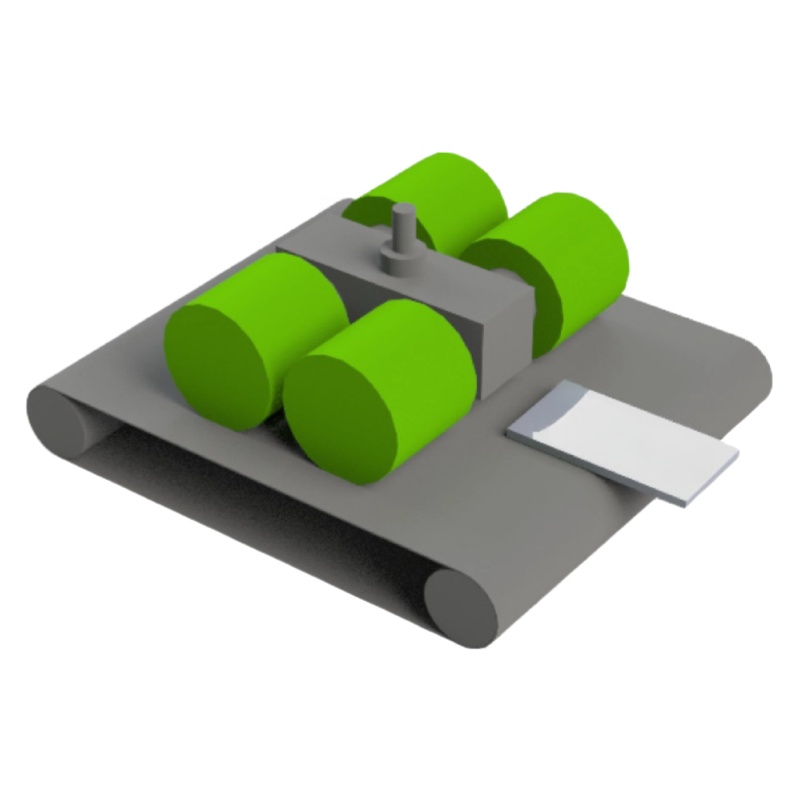

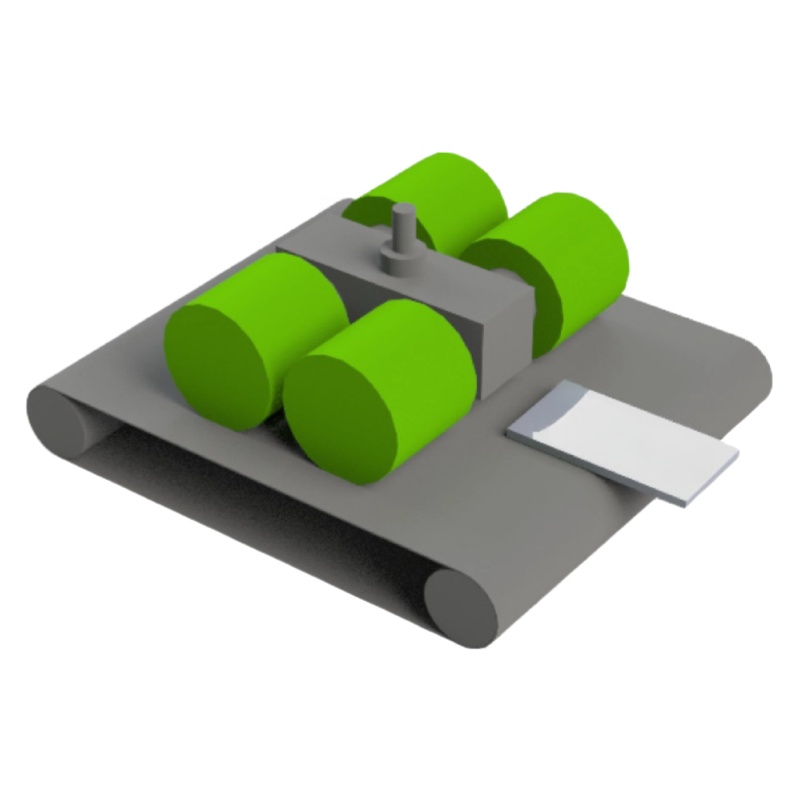

MSP-M800 Deburring and Edge Rounding Machine

The MSP-M800 is a high-performance deburring and edge rounding machine designed for processing metal parts after flame cutting, laser cutting, and plasma cutting. It efficiently removes burrs, rounds sharp edges, and ensures a smooth surface finish for steel, aluminum, and stainless steel materials.

Key Features & Benefits

✅ Deburring & Edge Rounding: Removes burrs and rounds sharp edges, improving safety and surface quality.

✅ Wide Material Compatibility: Processes steel, aluminum, and stainless steel with thicknesses from 0.5 to 80mm.

✅ Magnetic & Vacuum Holding System: Ensures stability during processing, even for small parts.

✅ Flap Wheel Technology: Equipped with 300×300mm flap wheels for efficient edge rounding.

✅ Adjustable Conveyor Speed: Ranges from 0.5 to 6.0 m/min for optimized workflow.

✅ Heavy-Duty Performance: Can handle metal sheets up to 800mm wide and weighing up to 350kg.

✅ Integrated Dust Extraction: Requires 3000m³/h deduster for clean operation.

Technical Specifications

| Specification | Details |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Deburring, Edge Rounding |

| Material Thickness (mm) | 0.5-80 |

| Max. Material Width (mm) | 800 |

| Min. Part Dimensions (mm) | 50×50 |

| Max. Material Weight (kg) | 350 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Minimum Deduster Need (m³/h) | 3000 |

| Machine Power (kW) | 6.3 / 11.8 |

| Machine Weight (kg) | 2100 |

| Holder System | Magnetic (Vacuum Optional) |

| Flap Wheel Dimensions (mm) | 300 × 300 |