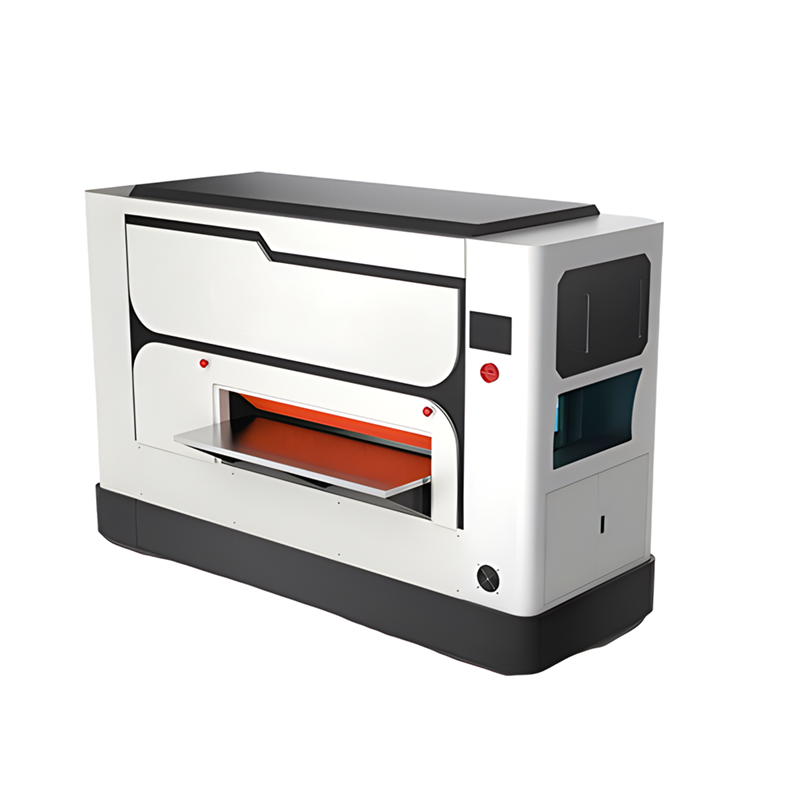

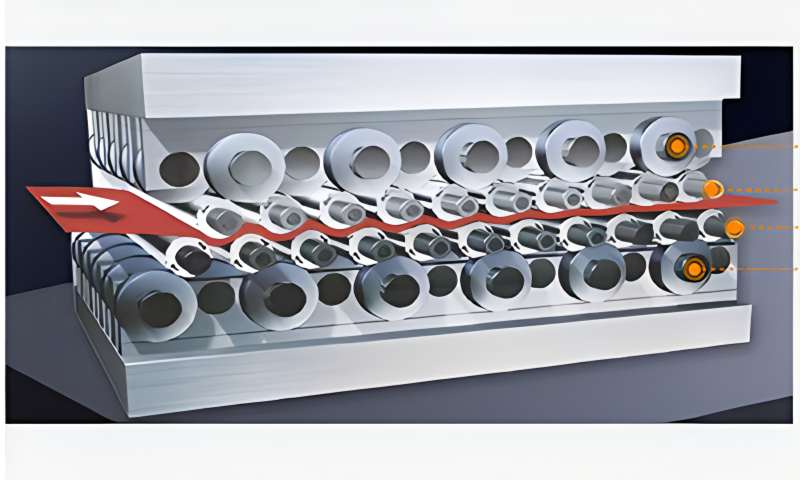

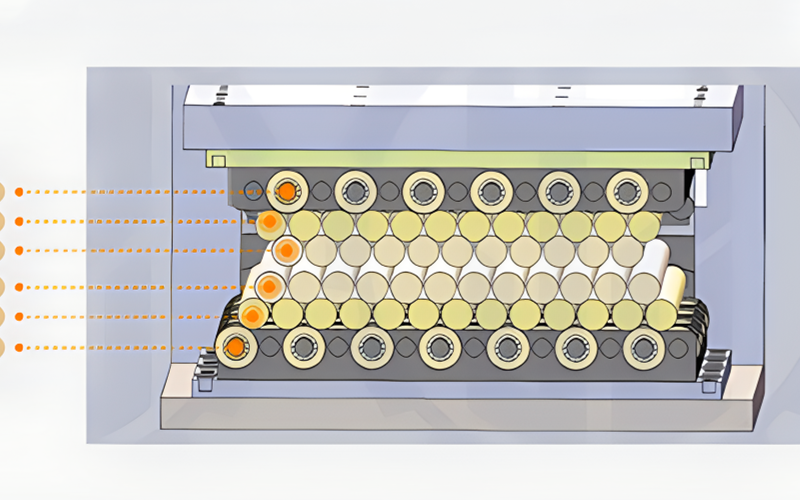

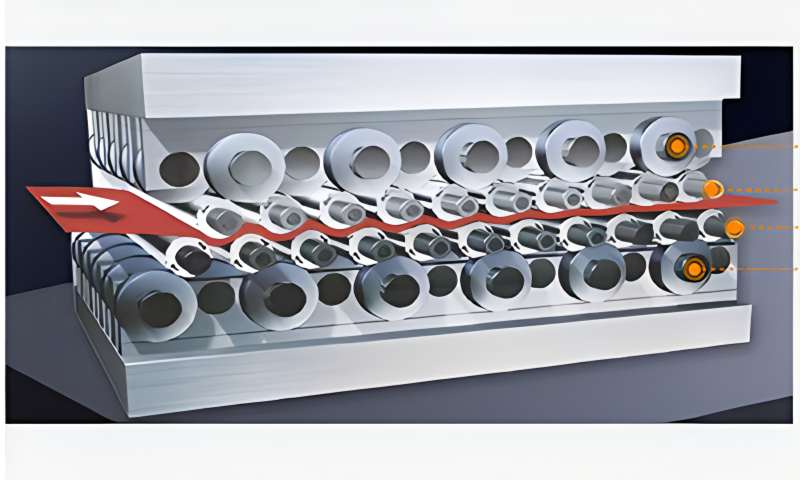

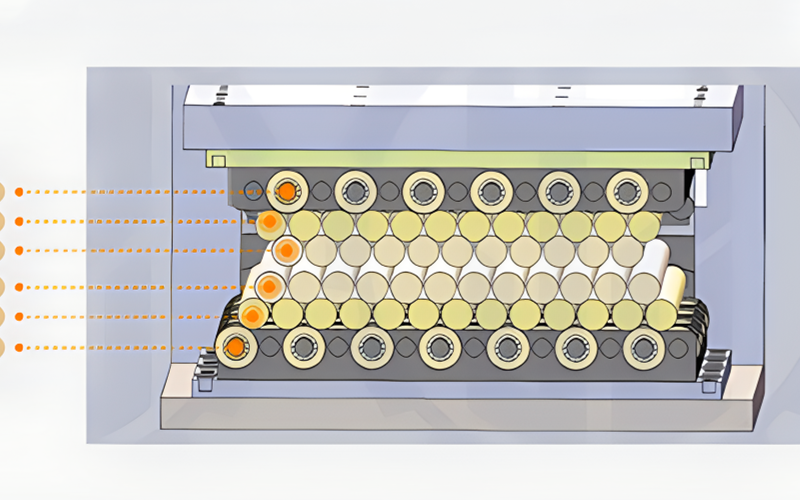

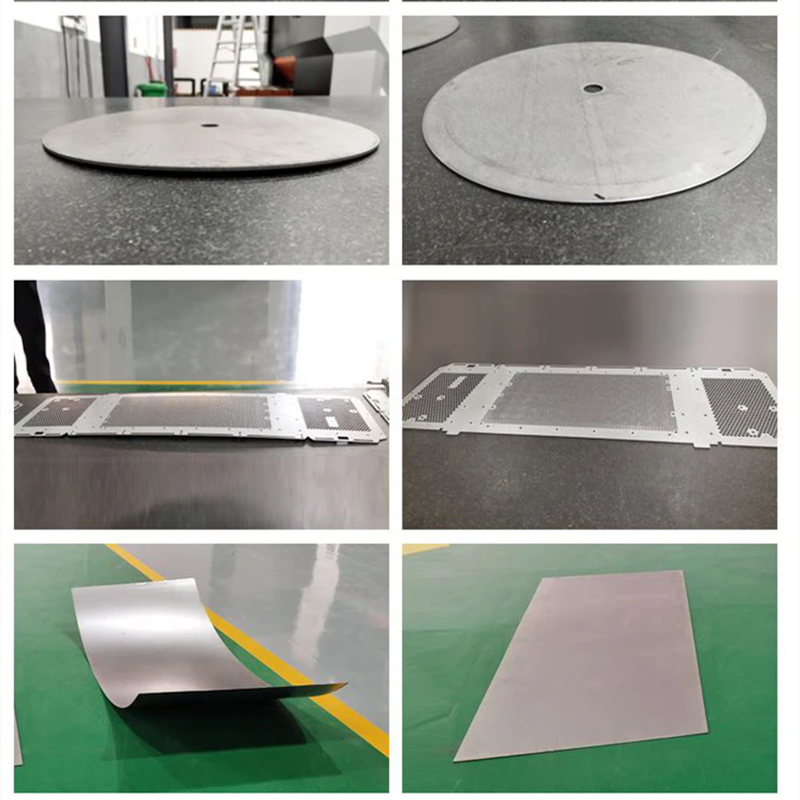

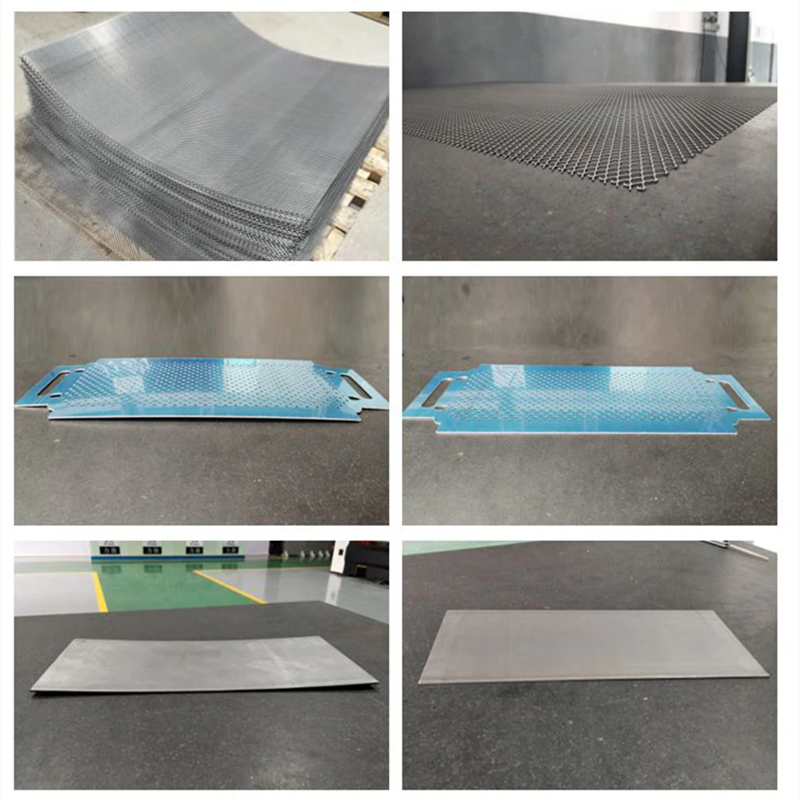

A Part Leveling Machine designed for straightening metal sheets and parts with a roll diameter of 60mm, leveling thickness between 1mm and 6mm, and leveling width ranging from 400mm to 3200mm is a highly specialized piece of equipment. This type of machine is essential for industries where precision flatness and consistent quality of metal sheets and parts are required.

Key Specifications:

Key Features:

Precision Leveling:

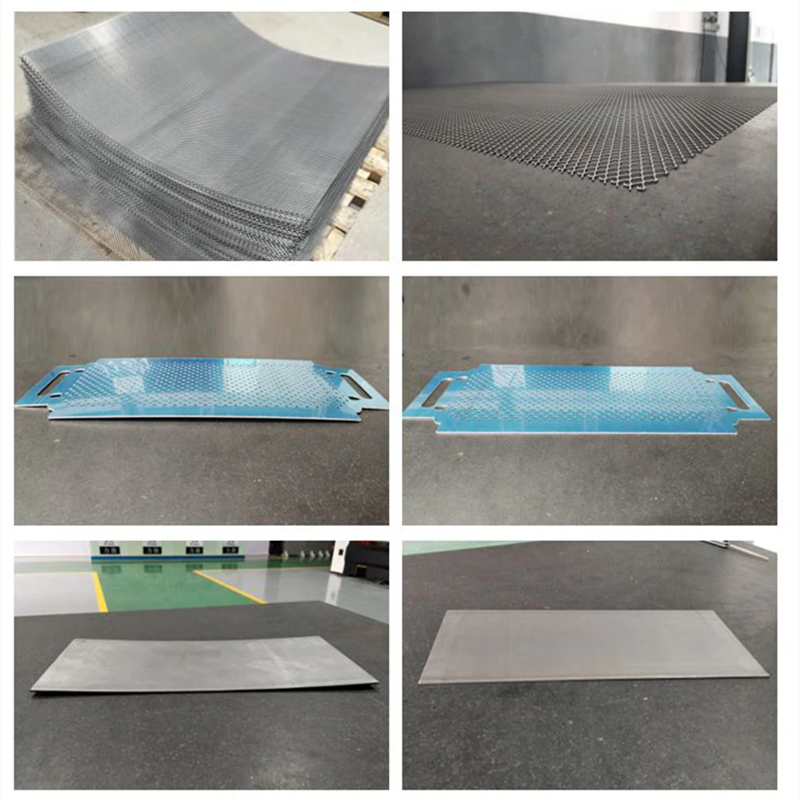

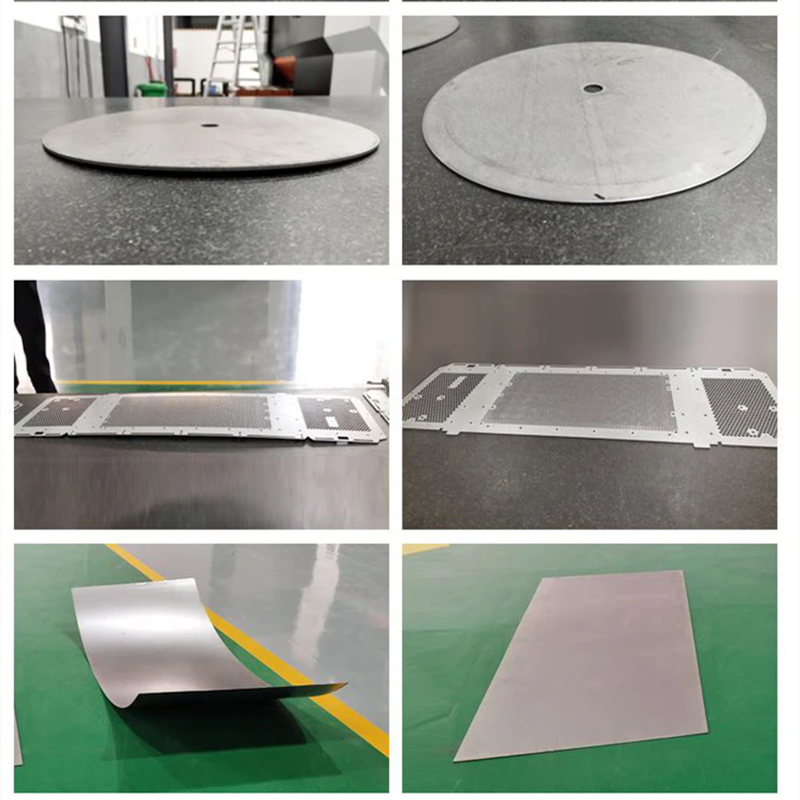

Achieves high levels of flatness by gradually reducing bends, warps, and other imperfections in metal sheets and parts.

Suitable for processing materials like stainless steel, carbon steel, aluminum, and other metals.

Adjustable Roll Settings:

Robust Construction:

Automation Options:

High Throughput:

Versatility:

The machine can handle various materials and applications, from sheet metal fabrication to part straightening in industries like automotive, aerospace, construction, and manufacturing.

Applications:

Automotive Industry: Leveling body panels, chassis components, and other critical parts.

Construction: Straightening metal sheets used in structural applications like roofing, siding, and framing.

Aerospace: Ensuring flatness in parts used in aircraft manufacturing where precision is critical.

Metal Fabrication: General leveling and straightening of parts and sheets for various manufacturing processes.

Heavy Machinery: Processing thick metal plates used in the construction of heavy machinery and equipment.

Benefits:

Improved Product Quality: Ensures parts and sheets meet precise flatness and tolerance requirements, reducing rework and improving assembly processes.

Increased Production Efficiency: High throughput and automation options reduce production time and labor costs.

Versatile Use: Capable of handling a wide range of materials and applications, making it a valuable addition to any manufacturing operation.

This type of part leveling machine is ideal for companies looking to enhance their production capabilities, ensuring that metal sheets and parts are consistently flat and ready for further processing or assembly.

Conclusion:

The choice between CNC, hydraulic, and mechanical leveling machines depends on the specific requirements of the application, including the level of precision needed, material thickness, production volume, and budget. CNC leveling machines are ideal for high-precision and high-volume applications, while hydraulic machines are better suited for heavy-duty tasks. Mechanical leveling machines offer a cost-effective solution for less demanding applications.