Part Leveling Machines are specialized equipment designed to ensure the flatness and precision of metal parts, sheets, and heavy plates. These machines are critical for applications where high precision and consistent flatness are required, particularly in industries like automotive, aerospace, construction, and manufacturing.

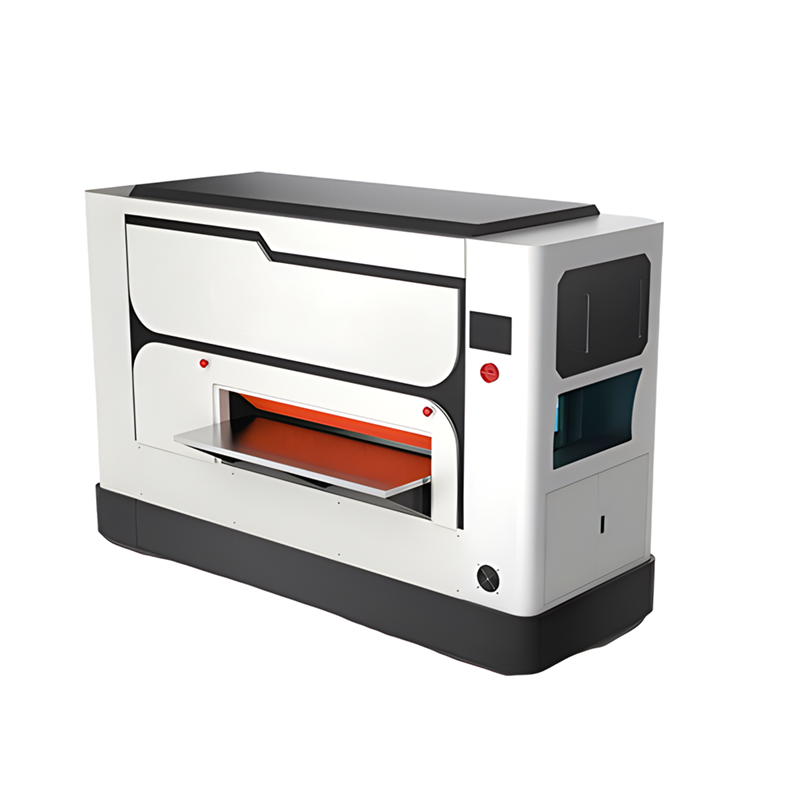

Precision Levelers:

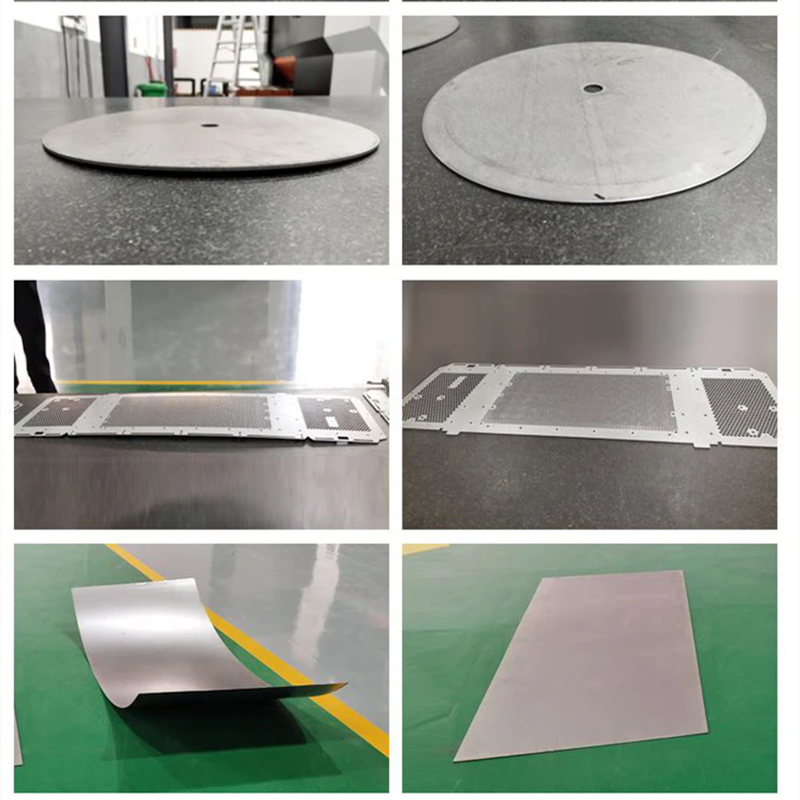

Precision levelers are used for fine-tuning the flatness of metal sheets and parts. They are capable of handling materials with thicknesses ranging from thin sheets to moderately thick plates. The goal is to remove any warping, bending, or other distortions in the material to meet tight tolerances.

Typical Material Thickness Range: 0.8mm to 4mm

Applications: Automotive components, aerospace parts, precision sheet metal fabrication, electronics, and more.

Key Features:

High Precision Control: Ensures exact flatness and dimensional accuracy.

Versatile Material Handling: Suitable for different materials, including stainless steel, aluminum, copper, and more.

Consistency: Provides uniform results across the entire workpiece.

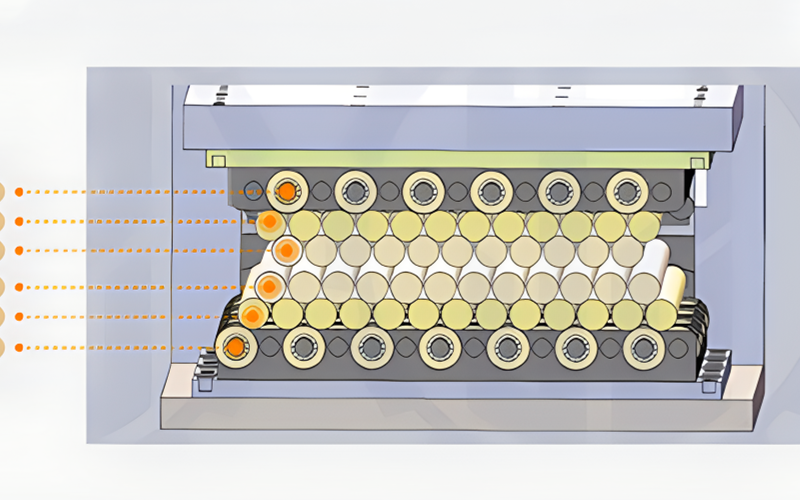

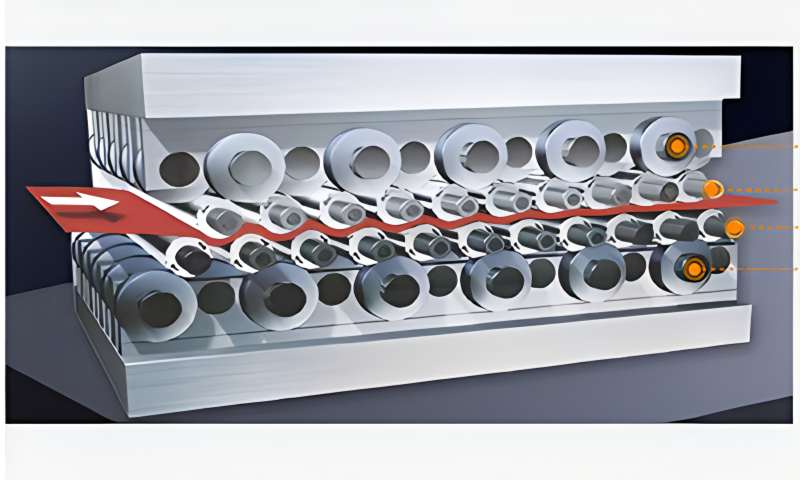

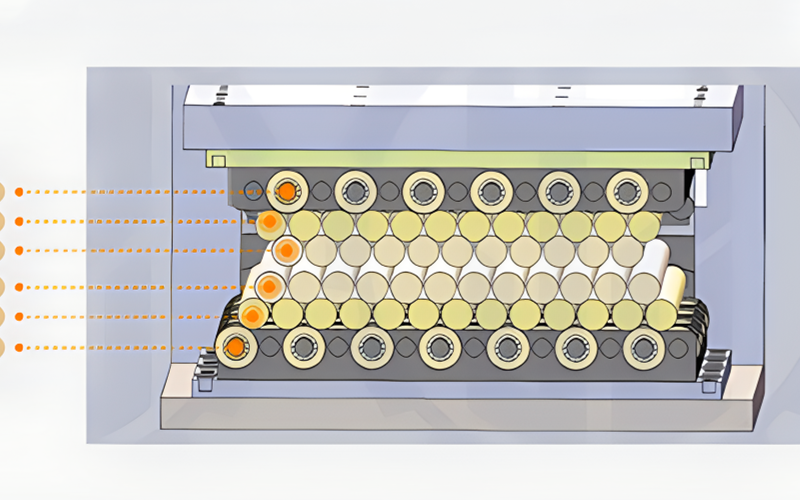

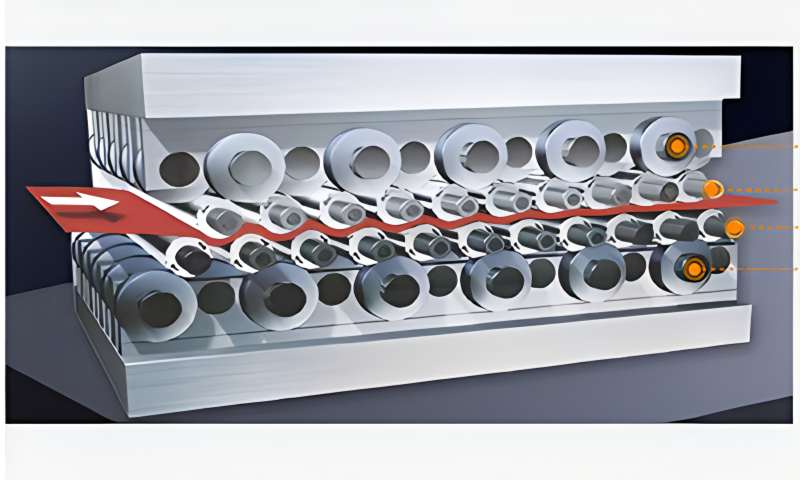

Roller Levelers:

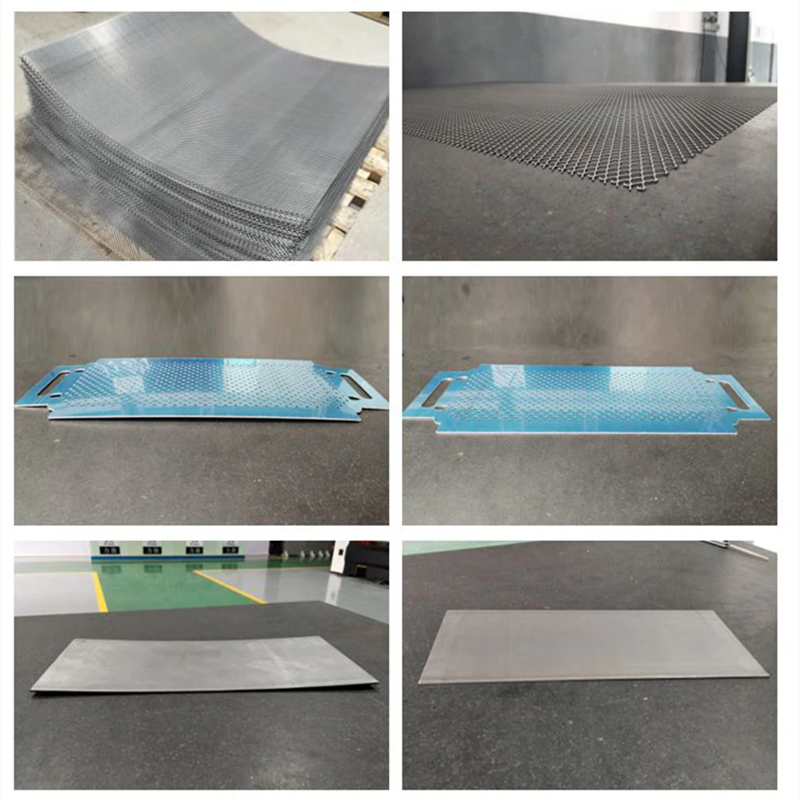

Roller levelers use a series of rollers to gradually flatten metal sheets and plates. These machines are particularly effective for processing both thin and thick materials, ensuring consistent flatness throughout the workpiece.

Typical Material Thickness Range: 0.8mm to 4mm (can vary based on the machine's design).

Applications: Used in industries requiring high levels of flatness for parts and sheets, such as automotive, heavy machinery, and construction.

Key Features:

Multi-Roll System: Provides even pressure distribution, gradually correcting the flatness of the material.

High Throughput: Capable of processing large quantities of material quickly.

Durability: Designed to handle heavy-duty applications and continuous operation.

Key Benefits of Precision Levelers and Roller Levelers:

Improved Product Quality: Ensures that parts and sheets meet stringent flatness and tolerance requirements, which is critical for further processing and assembly.

Increased Production Efficiency: Reduces the need for rework or manual adjustments, leading to faster production times.

Versatility: Can handle a wide range of materials and thicknesses, making them suitable for diverse applications.

Durability and Reliability: Built to withstand continuous use in industrial environments.

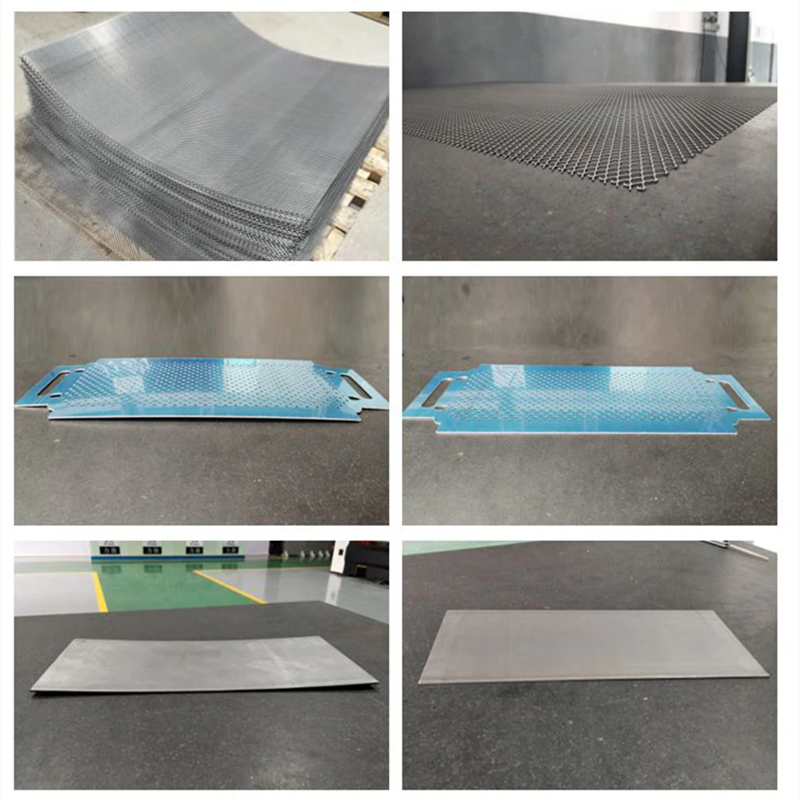

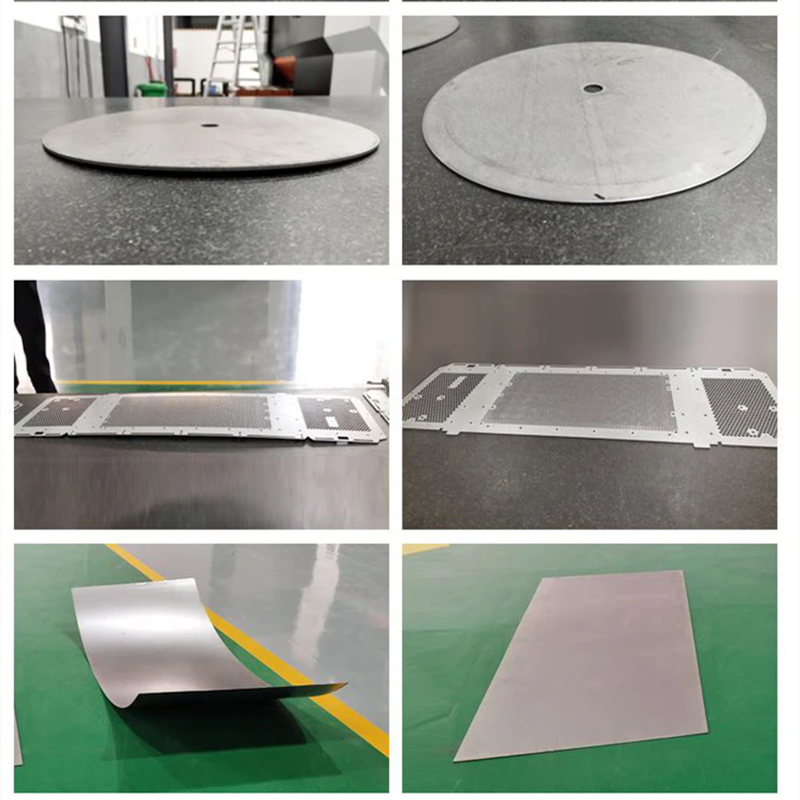

Materials Handled:

Stainless Steel

Carbon Steel

Aluminum

Copper

Other Non-ferrous Metals

Common Applications:

Automotive Industry: Ensuring flatness for components that require precision fitting.

Aerospace Industry: Flattening materials used in aircraft construction where tolerances are critical.

Metal Fabrication: General flattening and leveling for various parts used in manufacturing.

Heavy Machinery: Leveling thick plates used in the construction of heavy-duty machinery.

By choosing the right part leveling machine, manufacturers can achieve superior flatness and quality in their products, meeting the demands of various industries and applications.

Conclusion:

The choice between CNC, hydraulic, and mechanical leveling machines depends on the specific requirements of the application, including the level of precision needed, material thickness, production volume, and budget. CNC leveling machines are ideal for high-precision and high-volume applications, while hydraulic machines are better suited for heavy-duty tasks. Mechanical leveling machines offer a cost-effective solution for less demanding applications.