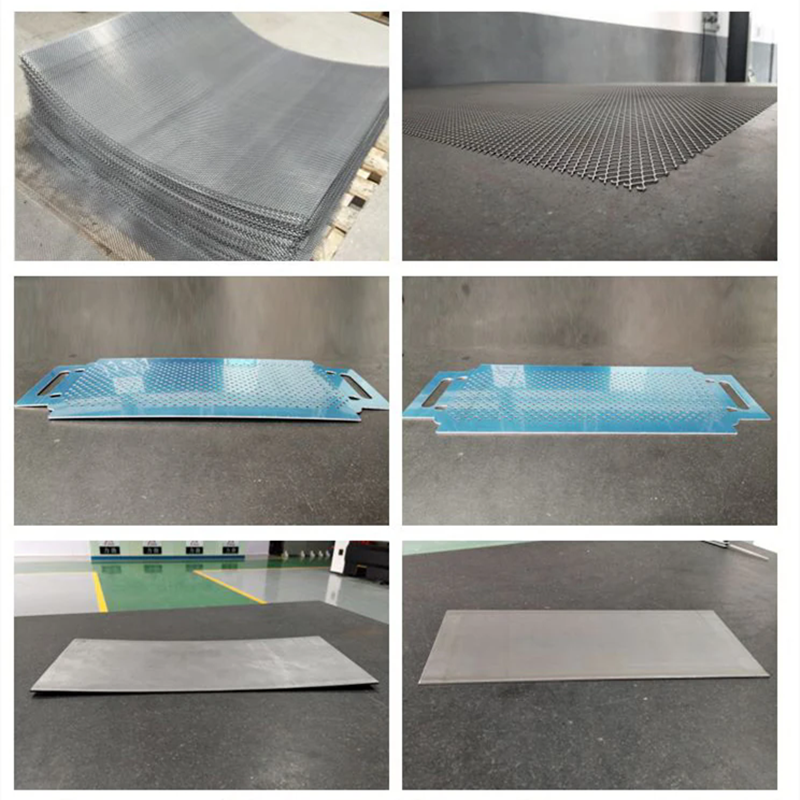

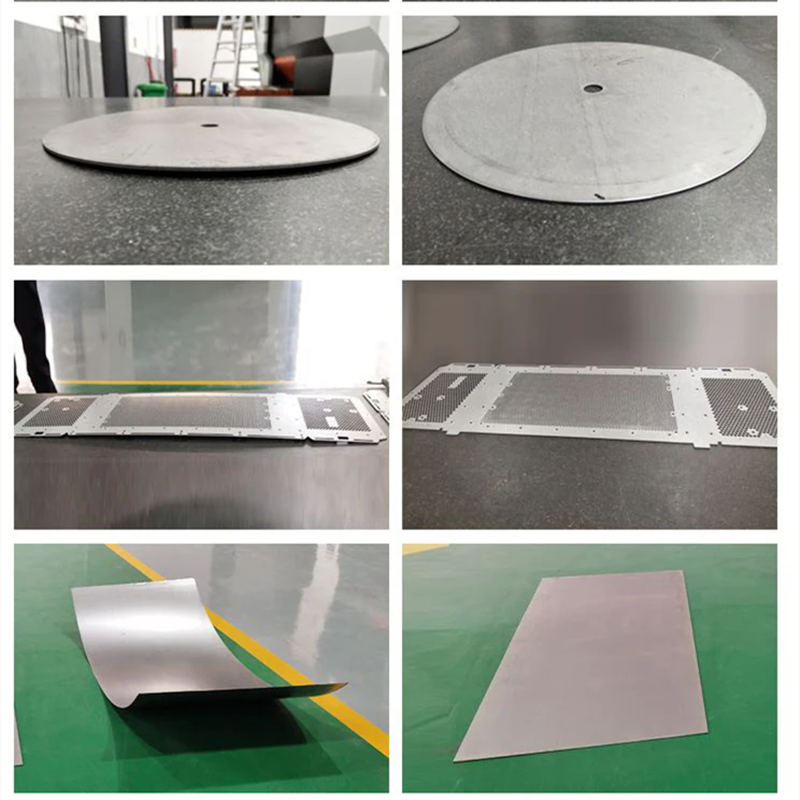

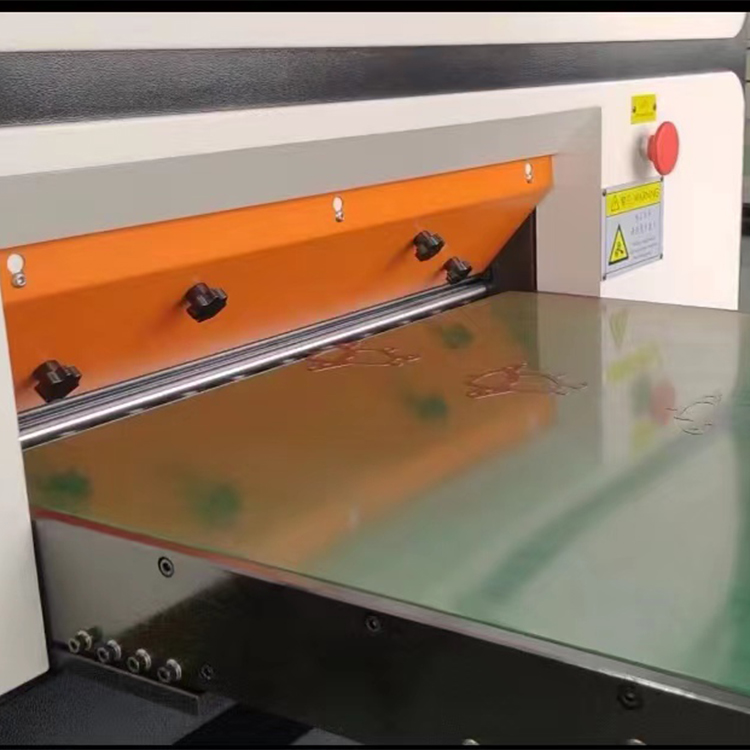

A roller leveling machine designed for processing metal sheets with a thickness range of 0.2-1.5 mm and a width of 200-700 mm is a versatile piece of equipment used to achieve precise flatness and remove distortions in thin to medium-gauge metal parts. This type of machine is crucial in industries where consistent quality and precision are required.

Key Features of a Roller Leveling Machine for 0.2-1.5 mm Thickness and 200-700 mm Width:

Processing Range:

Thickness: Capable of leveling metal sheets with a thickness from 0.2 mm to 1.5 mm.

Width: Designed to handle sheet widths between 200 mm and 700 mm, suitable for medium-sized metal parts.

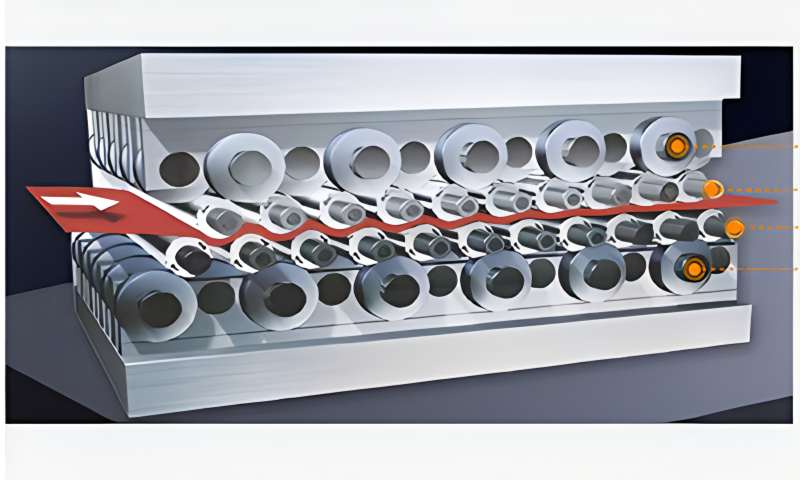

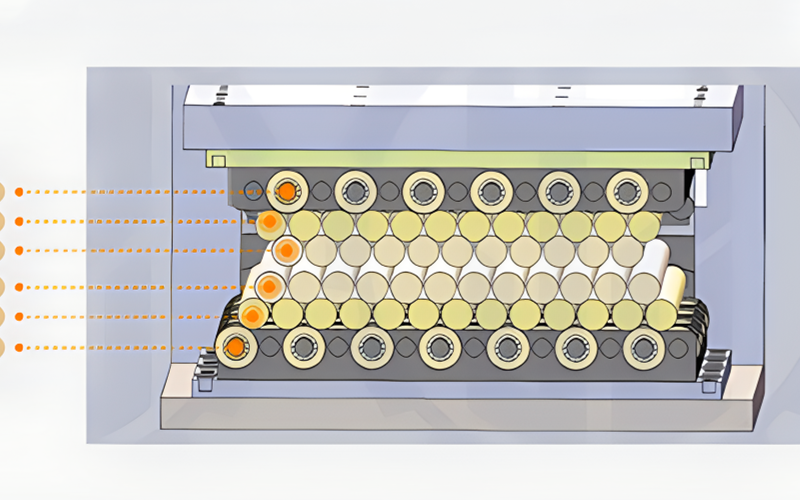

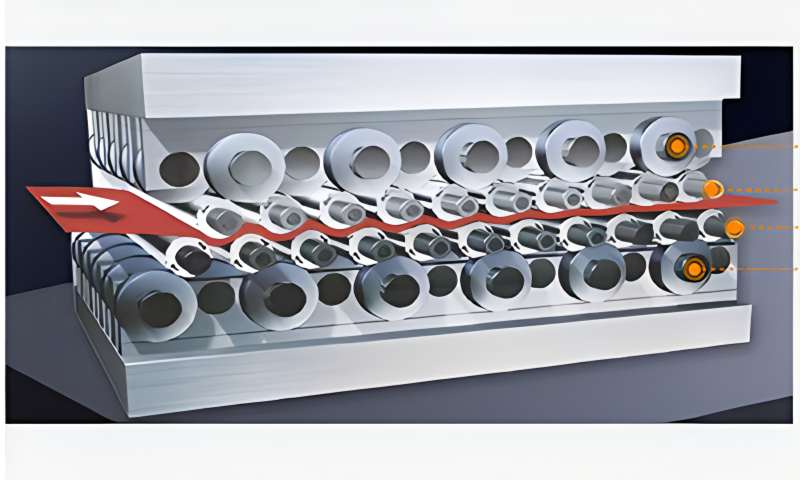

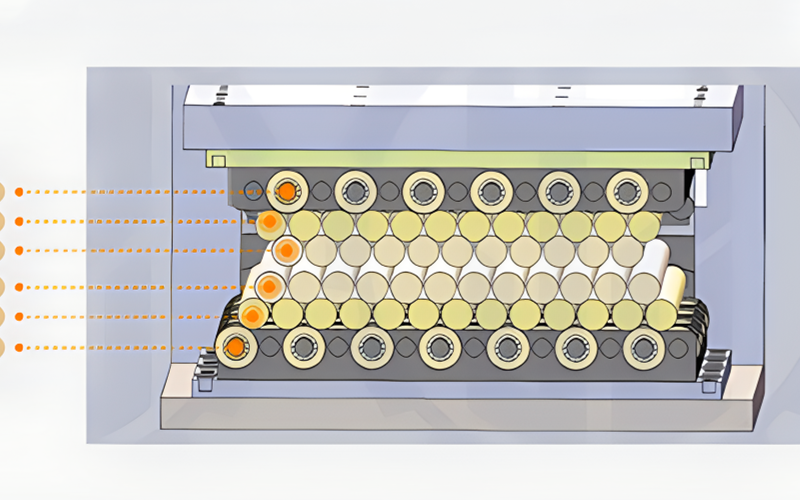

Roller Configuration:

Number of Rollers: Multiple upper and lower rollers are arranged in a staggered pattern to apply uniform pressure across the sheet. The number of rollers typically ranges from 11 to 23, depending on the model.

Roller Diameter: Rollers are engineered to provide precise leveling for thin to medium-gauge materials.

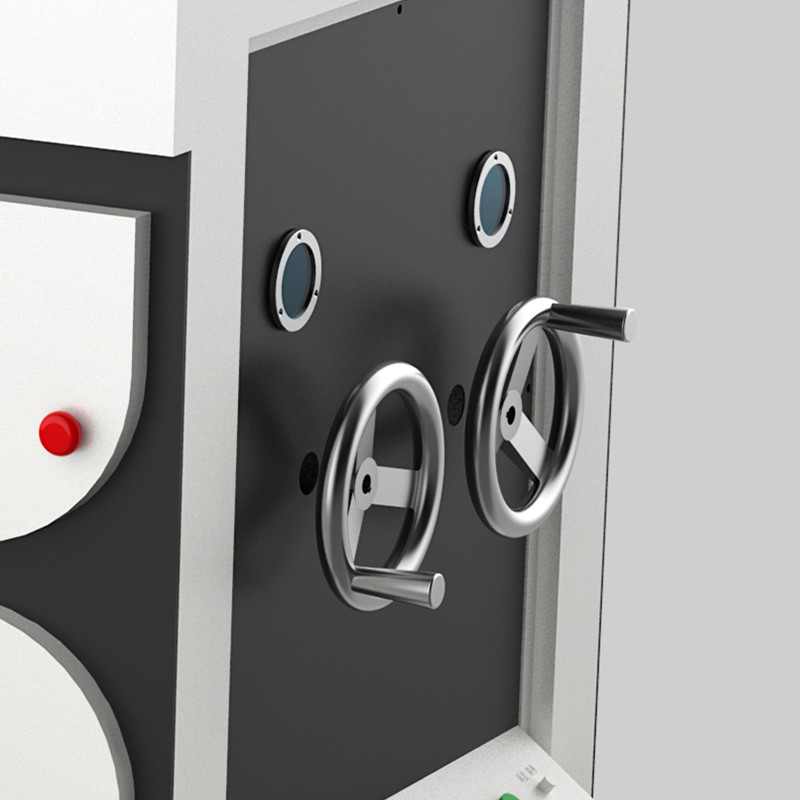

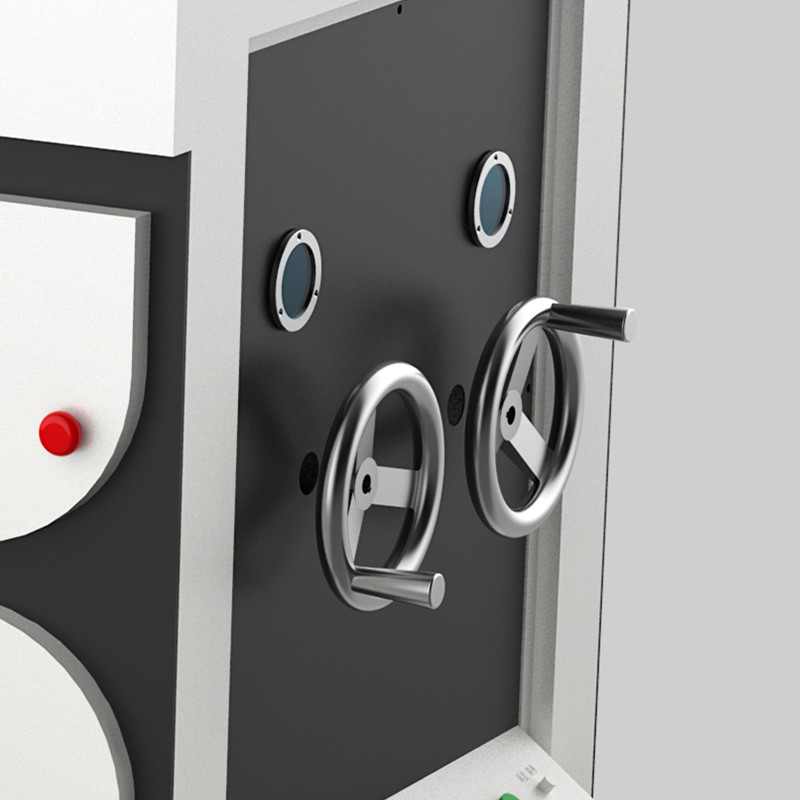

Adjustable Rollers:

Gap Adjustment: The roller gaps can be adjusted automatically or manually to accommodate different material thicknesses, ensuring precise leveling.

Servo-Controlled Adjustment: Some machines feature servo motors that provide accurate and repeatable adjustments, enhancing precision.

Automation and Controls:

CNC Controls: Advanced models may include CNC controls for automatic roller adjustments and precise settings tailored to specific materials.

User-Friendly Interface: A digital control panel allows operators to set parameters such as roller pressure, feed speed, and material thickness, making the machine easy to operate.

High Precision:

Flatness Tolerance: The machine is designed to achieve tight flatness tolerances, which is critical for applications requiring high precision.

Consistent Results: Ensures consistent leveling across the entire sheet, eliminating defects such as waves or buckling.

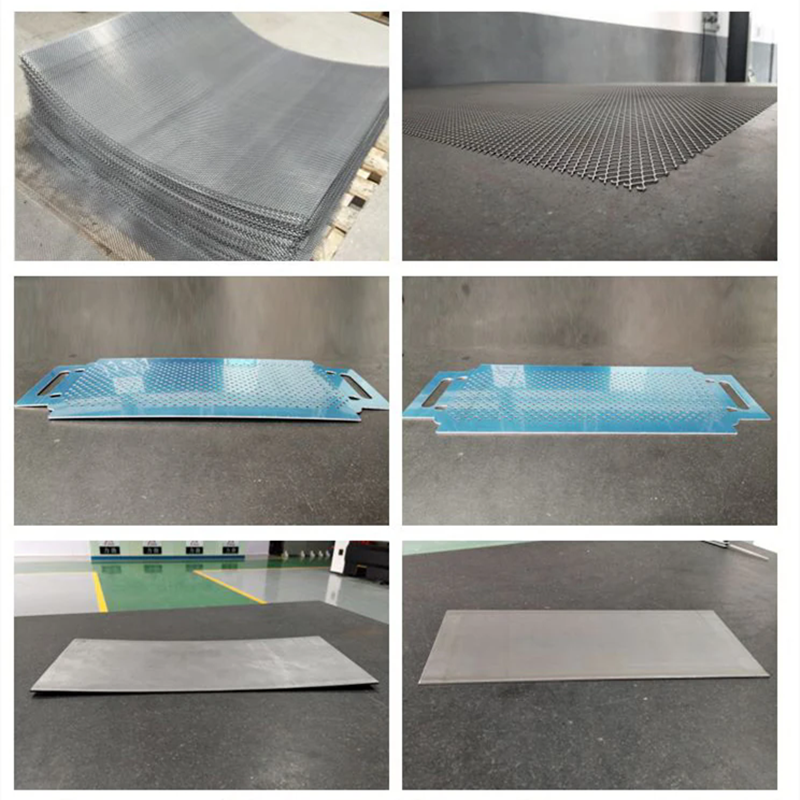

Robust Construction:

Heavy-Duty Frame: Built to withstand the demands of continuous operation and handle a variety of metals, including stainless steel, carbon steel, and non-ferrous metals.

Durability: Rollers and other components are made from high-strength materials to ensure long service life.

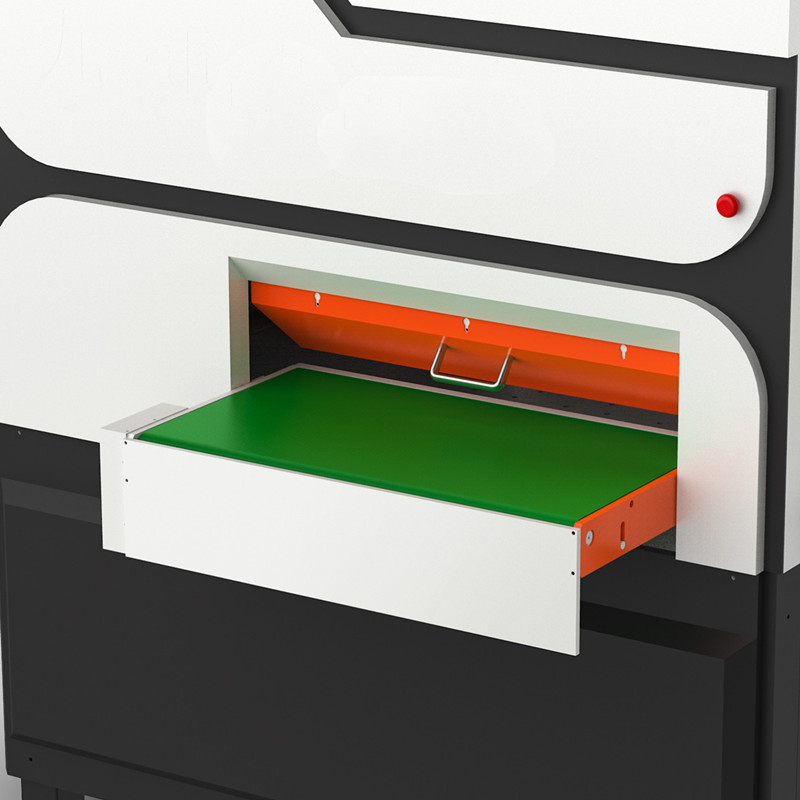

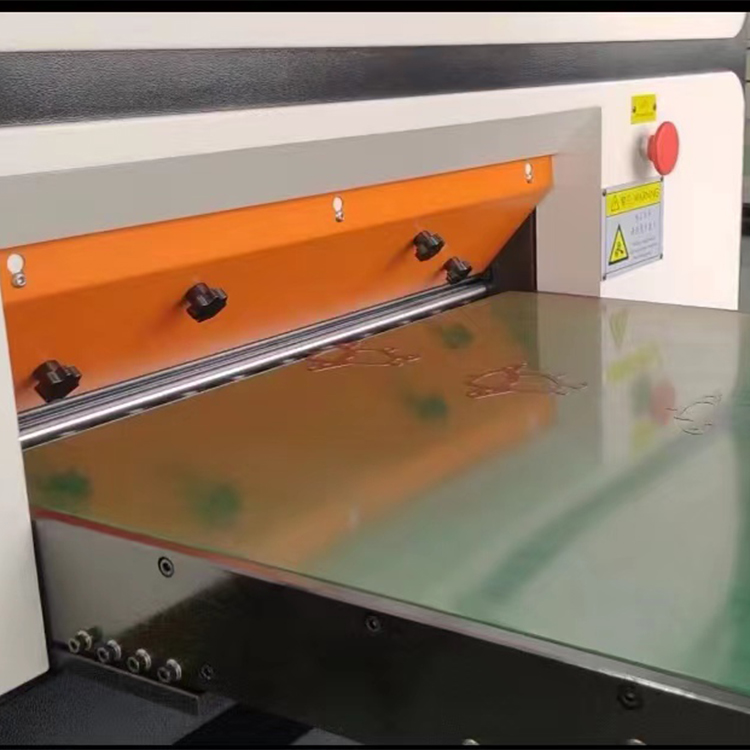

Feed System:

Variable Feed Speed: The feed speed is adjustable, allowing for customization based on material type and thickness.

Automatic Feeding: Some machines include an automatic feeding system to ensure smooth and consistent material flow.

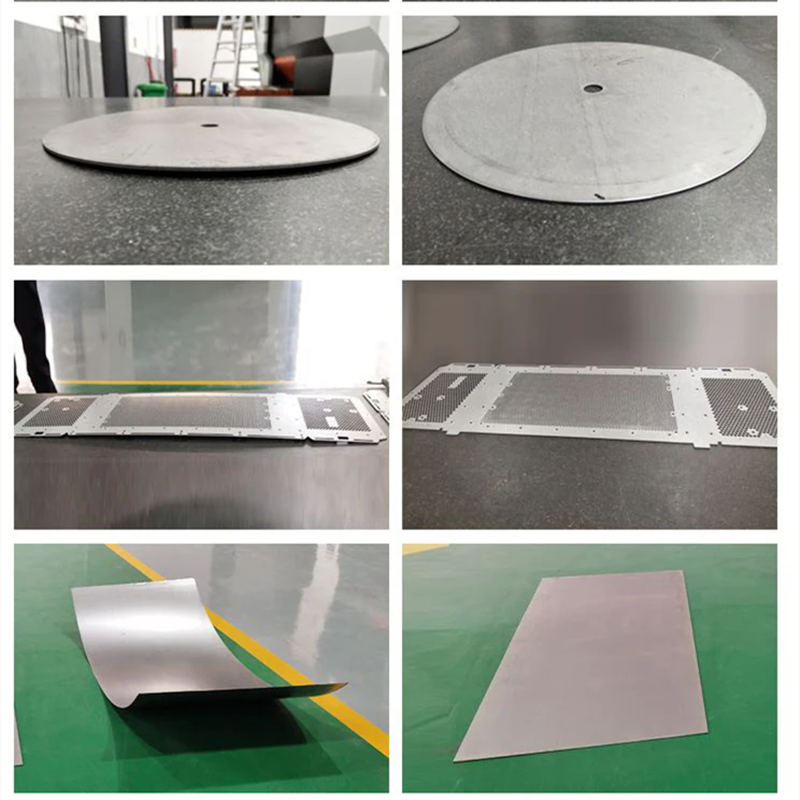

Applications:

Automotive Industry: Leveling metal sheets used in car body panels, components, and other parts where flatness is critical.

Electronics: Preparing thin metal sheets for use in electronic enclosures and components.

Aerospace: Ensuring precise flatness in metal sheets used in aerospace components.

General Manufacturing: Ideal for any industry that requires flat and distortion-free metal sheets.

Example Specifications:

Processing Width: 200-700 mm (suitable for medium-sized metal sheets)

Processing Thickness: 0.2-1.5 mm (suitable for thin to medium-gauge sheets)

Number of Rollers: 11 to 23 (depending on the specific machine model)

Roller Diameter: Optimized for thin material leveling

Feed Speed: Adjustable to match different production requirements

Power: Varies based on the machine size and capabilities, typically equipped with sufficient power to handle the specified range of materials

Types of Roller Leveling Machines:

Manual Roller Leveling Machines: Suitable for smaller production runs with manual roller adjustments.

Hydraulic Roller Leveling Machines: Use hydraulic pressure for roller adjustments, offering precise control for more demanding applications.

CNC Roller Leveling Machines: Feature automated adjustments and CNC controls for high-precision and high-volume production environments.

Benefits:

Improved Flatness: Achieves a uniform and flat surface, essential for further processing or assembly.

High Precision: Delivers consistent and repeatable results with precise control over roller adjustments.

Versatility: Can process various materials, including stainless steel, carbon steel, and non-ferrous metals.

Efficiency: Reduces the need for manual intervention, increasing throughput and reducing labor costs.

This roller leveling machine is ideal for industries that require precise flatness and high-quality surface finishes on metal sheets and parts.