Sheet Leveling Machines

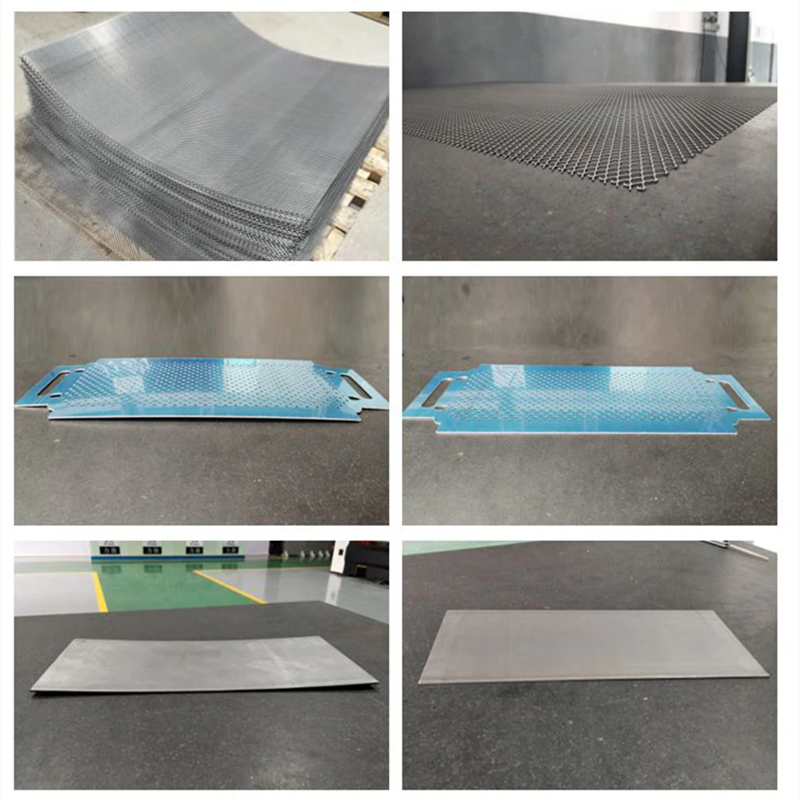

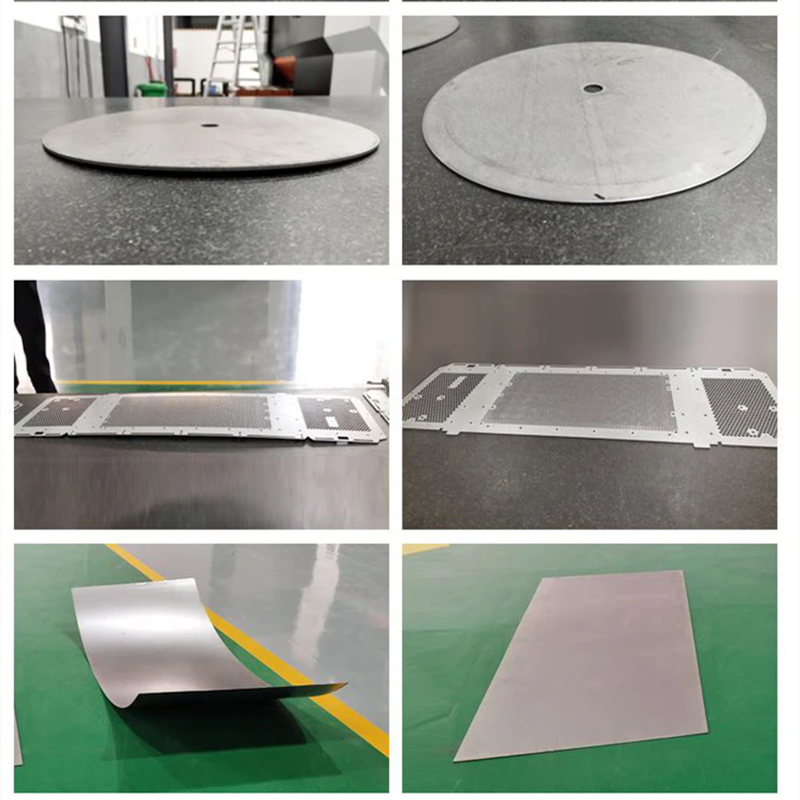

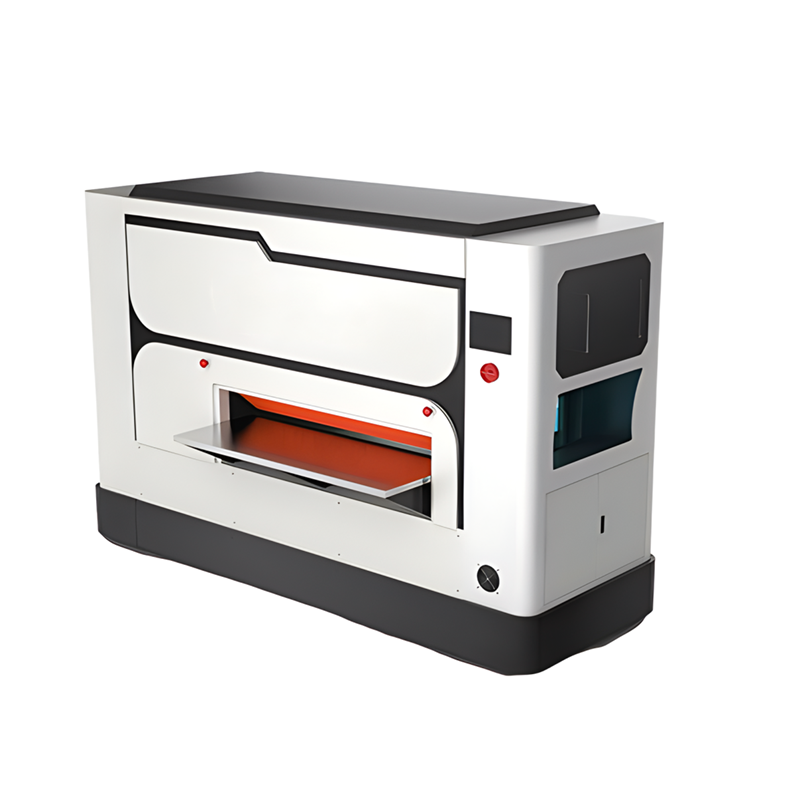

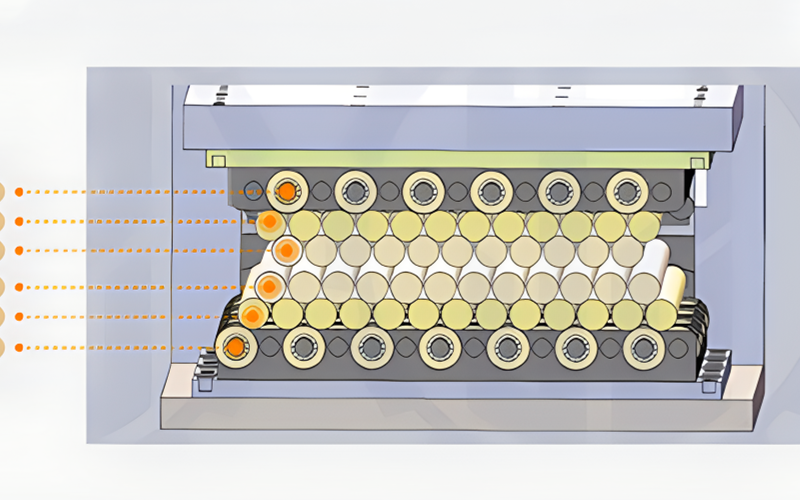

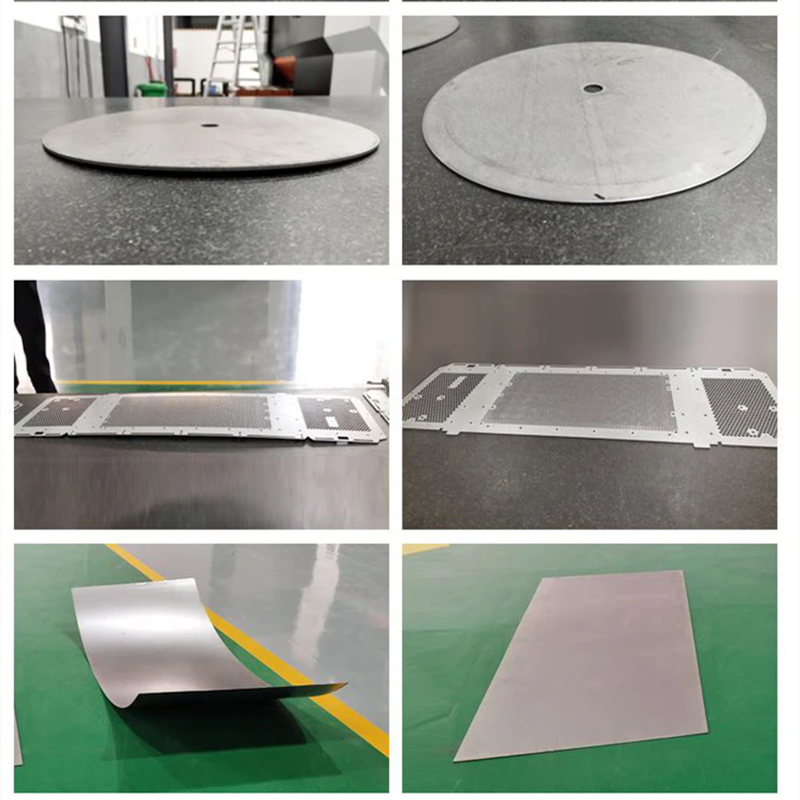

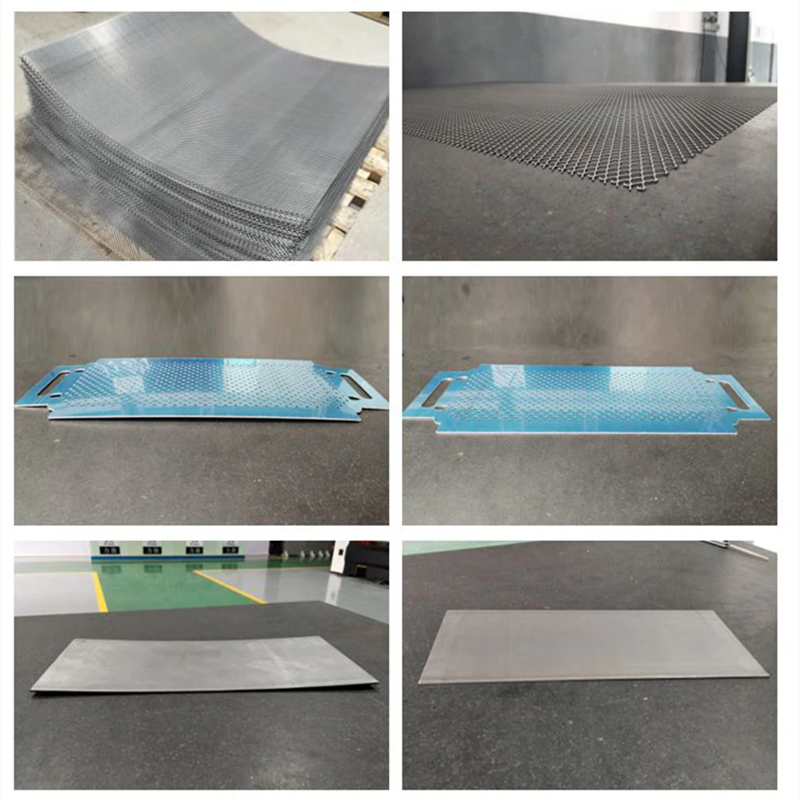

Sheet leveling machines are essential tools used in various industries to correct flatness imperfections in metal sheets. These machines ensure that the sheets are flat and free from any bends, waves, or warps, making them suitable for further processing. There are several types of sheet leveling machines, each with different mechanisms and features to meet specific requirements. The main types include CNC leveling machines, hydraulic leveling machines, and mechanical leveling machines.

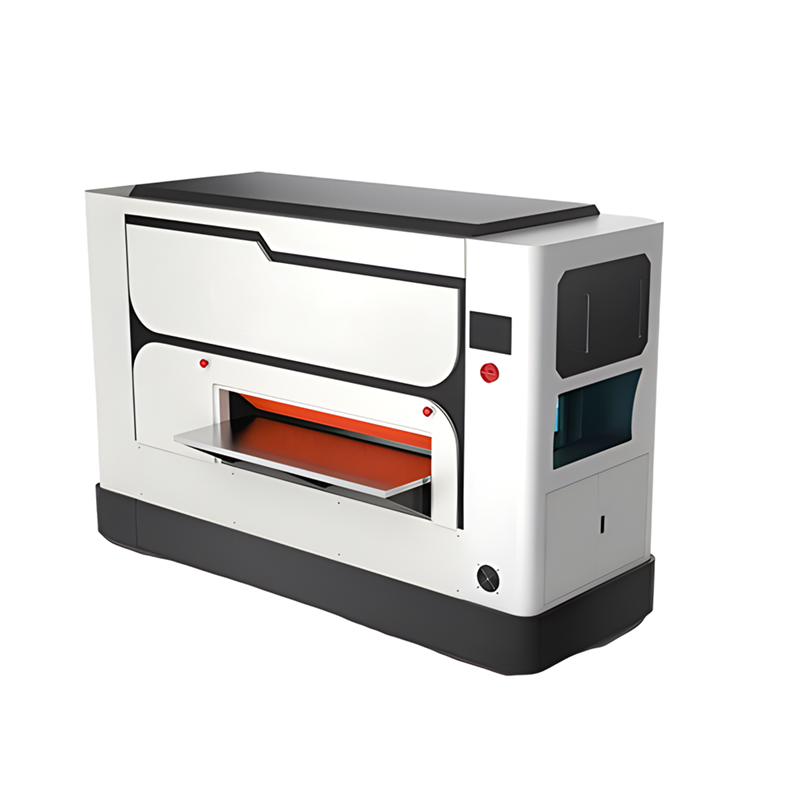

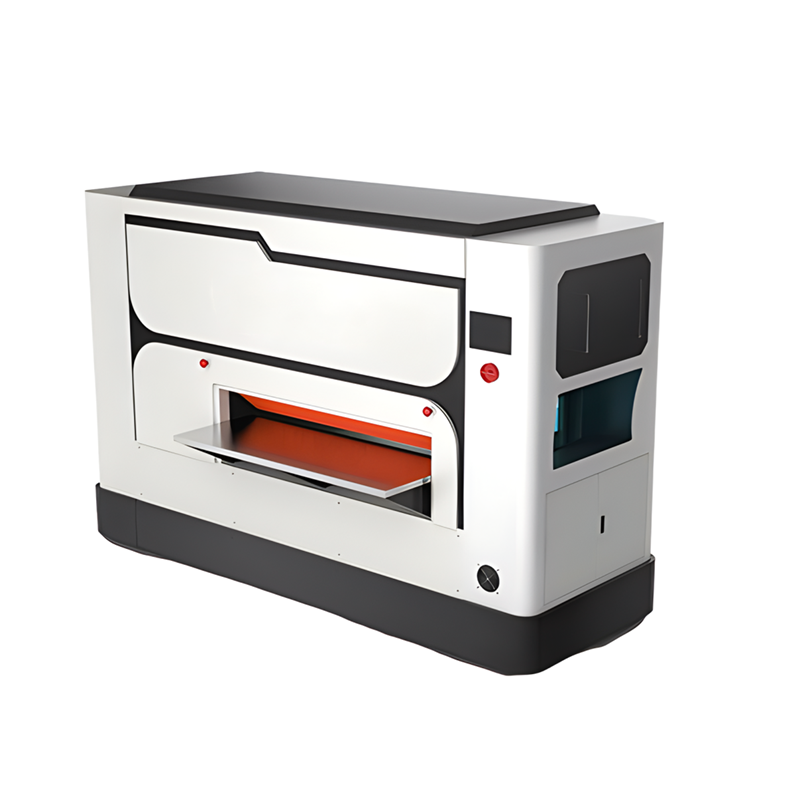

1. CNC Leveling Machines

Overview:

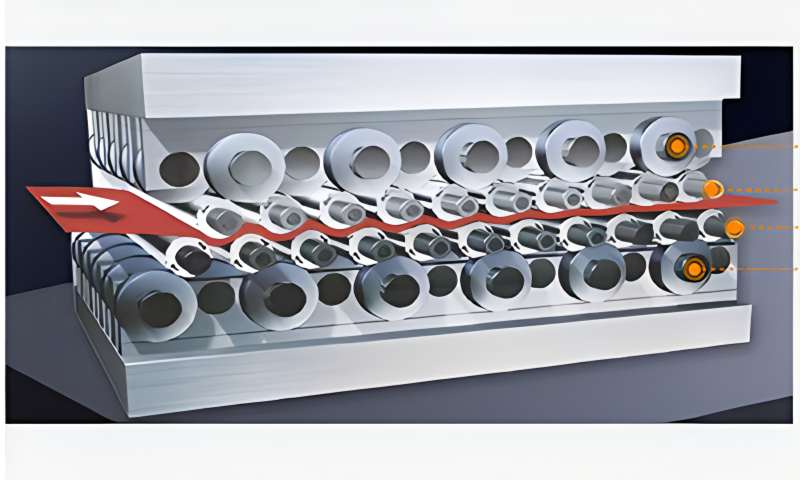

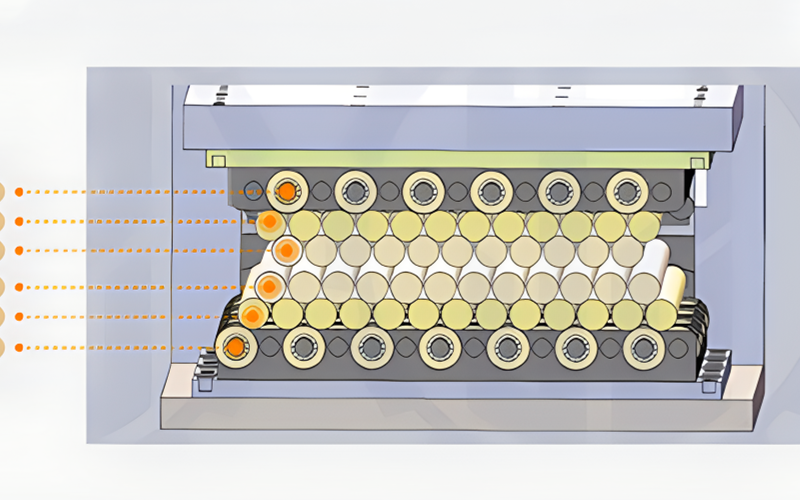

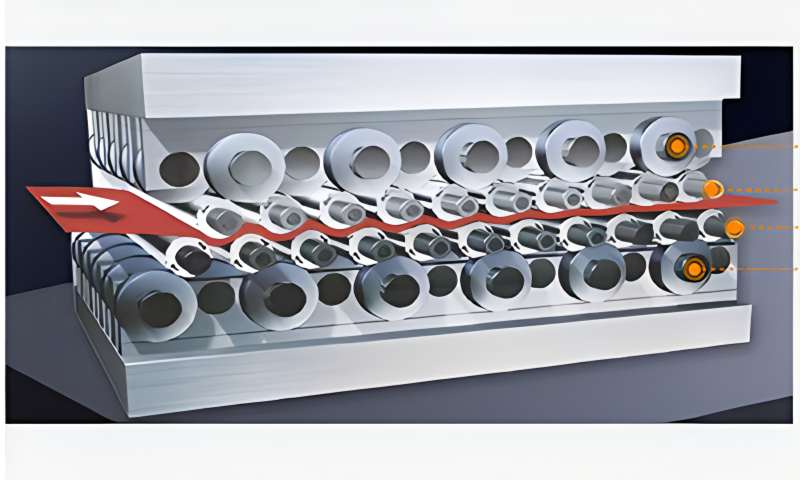

CNC (Computer Numerical Control) leveling machines offer the highest level of precision and automation in sheet leveling. They are equipped with advanced control systems that allow for precise adjustments to the rollers and other components, ensuring consistent results with minimal human intervention.

Key Features:

Precision Control: Automated control systems allow for precise adjustment of leveling parameters, making them ideal for applications requiring high accuracy.

Automation: CNC leveling machines can be programmed to handle different materials and thicknesses, reducing the need for manual adjustments.

Versatility: Capable of leveling a wide range of materials, including stainless steel, aluminum, copper, and more.

Real-time Monitoring: Equipped with sensors and feedback systems that monitor the leveling process in real-time, ensuring optimal results.

Efficient Operation: CNC leveling machines are designed for high-speed, continuous operation, making them suitable for high-volume production environments.

Applications:

Precision metalworking industries, such as automotive, aerospace, and electronics manufacturing.

Industries where high levels of flatness are required, such as semiconductor fabrication and medical device manufacturing.

2. Hydraulic Leveling Machines

Overview:

Hydraulic leveling machines use hydraulic power to adjust the rollers and apply force to the sheet metal, correcting any flatness issues. These machines are known for their robustness and ability to handle thicker and more challenging materials.

Key Features:

High Force Output: Hydraulic systems provide the power needed to level thicker and harder materials, such as heavy-duty steel plates.

Adjustable Pressure: Operators can easily adjust the hydraulic pressure to suit different materials and thicknesses.

Durability: Built with heavy-duty components, hydraulic leveling machines are designed to withstand continuous operation in demanding environments.

Manual and Semi-Automatic Options: While some hydraulic leveling machines offer manual control, others come with semi-automatic features for increased efficiency.

Applications:

Shipbuilding, construction, and heavy machinery industries where thick metal plates and sheets are common.

Applications that require significant force to achieve the desired level of flatness.

3. Mechanical Leveling Machines

Overview:

Mechanical leveling machines use a system of gears, levers, and mechanical rollers to level sheet metal. These machines are typically more straightforward and less expensive than their CNC and hydraulic counterparts, making them a good choice for smaller operations or less demanding applications.

Key Features:

Cost-Effective: Mechanical leveling machines are generally less expensive to purchase and maintain, making them suitable for small to medium-sized operations.

Simple Operation: These machines often have simpler controls, making them easier to operate and maintain.

Robust Construction: Designed to handle a wide range of materials, from thin sheets to moderately thick plates.

Manual and Automated Versions: Available in both manual and automated configurations, allowing for different levels of control and automation.

Applications:

Metal fabrication shops, HVAC, and general manufacturing where high precision is not the primary requirement.

Suitable for leveling thinner materials or less critical applications.

Comparative Summary:

CNC Leveling Machines:

Hydraulic Leveling Machines:

Precision: Moderate to High

Automation: Semi-automatic to manual

Material Range: Thick and heavy-duty materials

Best For: Heavy industries, such as shipbuilding and construction.

Mechanical Leveling Machines:

Precision: Moderate

Automation: Manual to semi-automatic

Material Range: Thin to medium thickness

Best For: Cost-conscious operations, small to medium-sized manufacturing.

Conclusion:

The choice between CNC, hydraulic, and mechanical leveling machines depends on the specific requirements of the application, including the level of precision needed, material thickness, production volume, and budget. CNC leveling machines are ideal for high-precision and high-volume applications, while hydraulic machines are better suited for heavy-duty tasks. Mechanical leveling machines offer a cost-effective solution for less demanding applications.