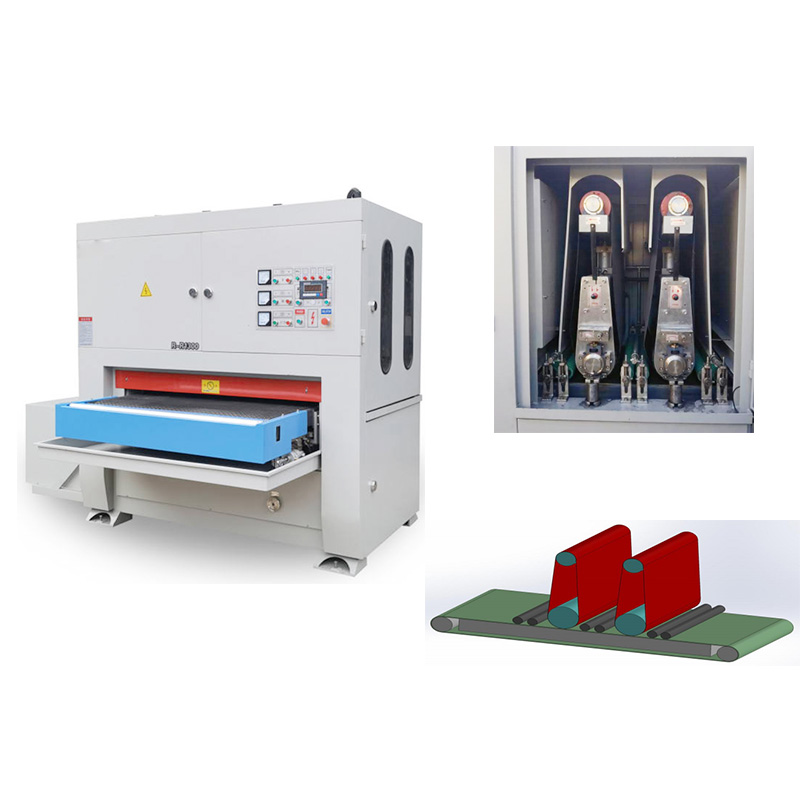

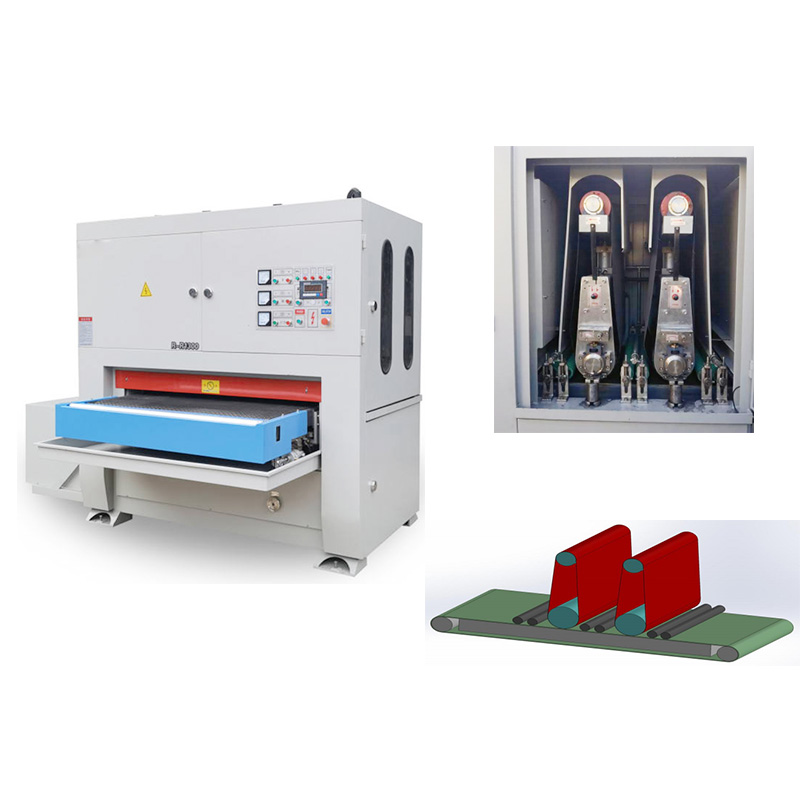

✅ RR1300 Wet Wide Belt Sander

Industrial Belt Sanding Machine for Heavy-Duty Metal Deburring, Finishing, and Surface Preparation

RR1300 Wet Sheet Metal Belt Sander

Heavy-Duty Wide Belt Sander for Industrial Sheet Metal Deburring & Finishing

The RR1300 is a high-capacity wet wide belt sander engineered for sheet metal grinding, deburring, oxide removal, and surface finishing. With an impressive working width of 1300mm, this machine is ideal for processing large-format metal sheets and panels made of stainless steel, mild steel, aluminum, and copper.

Thanks to its wet sanding system, the RR1300 delivers a consistent, high-quality surface finish while minimizing heat distortion and airborne dust — making it one of the best sanders for sheet metal processing in industrial environments.

✅ Key Features:

Model: RR1300

Working Width: 1300mm – suitable for large panels

Sanding Method: Wet belt grinding with water cooling

Belt Configuration: Single or dual belt heads (optional brush station)

Stable Feeding System: Heavy-duty conveyor with variable speed control

Water Filtration System: Ensures clean operation and extended abrasive life

Heavy-duty frame: Designed for continuous, industrial-scale production

Quick Belt Change System: Improves efficiency in multi-material production lines

⚙️ Technical Specifications (Typical Configuration):

| Parameter | Specification |

| Max. Working Width | 1300mm |

| Max. Working Height | 60mm |

| Min. Part Length | 150mm |

| Sanding Belt Size | 2200mm × 1300mm |

| Main Motor Power | 15–22 kW (per head) |

| Feeding Motor Power | 2.2 kW |

| Belt Speed | 15–30 m/s (adjustable) |

| Feed Speed | 0.5–6 m/min (adjustable) |

| Water Pump Power | 0.75 kW |

| Machine Size (L×W×H) | ~3000 × 2500 × 2200 mm |

| Weight | ~4000–5000 kg |

️ Applications:

Sheet metal deburring after laser, plasma, or flame cutting

Surface finishing for large stainless steel or aluminum panels

Oxide layer removal for painting, coating, or welding prep

Edge rounding and light grinding

Used in elevators, kitchen equipment, decorative panels, HVAC components, and steel furniture

Advantages:

Large-format capacity up to 1300mm wide

Wet processing ensures smooth finish and minimizes distortion

Consistent surface quality across full sheet width

Longer abrasive life with water-cooled operation

Ideal for continuous production lines with fast changeover and reliable operation