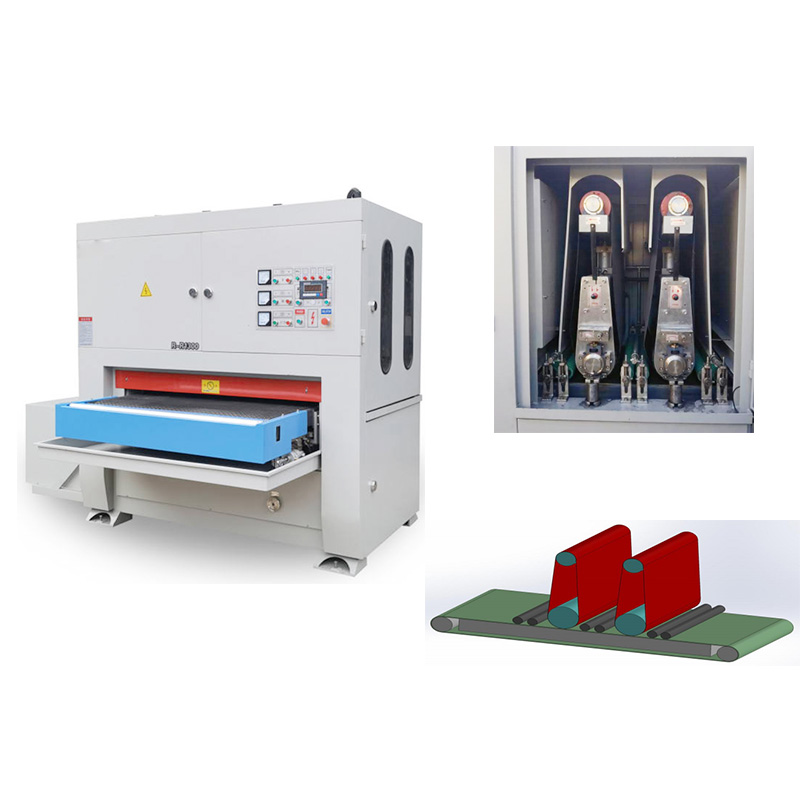

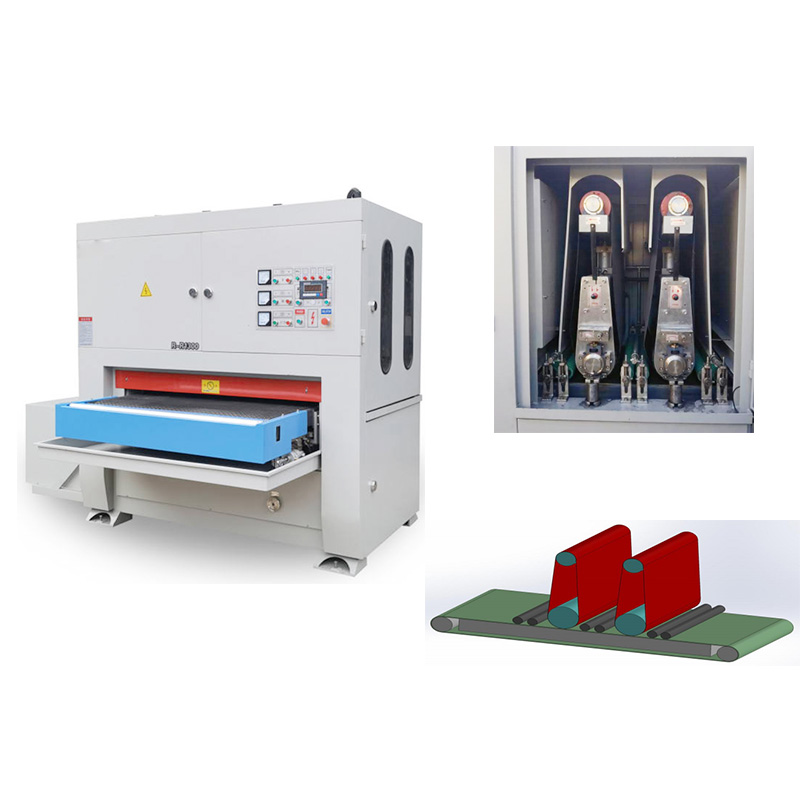

✅ RR1300 Wet Wide Belt Sander

Industrial Belt Sanding Machine for Heavy-Duty Metal Deburring, Finishing, and Surface Preparation

The RR1300 Wet Wide Belt Sander is a heavy-duty industrial sanding machine designed for professional metal finishing applications. Featuring a 1300mm wide working capacity, wet sanding technology, and robust construction, this machine ensures precision deburring, effective slag removal, oxide layer cleaning, and high-quality surface finishing for a variety of metals.

Key Features:

✅ Large Working Width: 1300mm (51 inches), perfect for wide metal sheets, panels, and components.

✅ Wet Sanding System: Equipped with water cooling to reduce heat buildup, eliminate dust, and achieve a cleaner, brighter finish without discoloration.

✅ Powerful Abrasive Belt Heads: Configurable with one or two sanding heads, ensuring flexibility for both heavy stock removal and fine polishing.

✅ Heavy-Duty Conveyor Belt: Industrial-grade conveyor feeding system with adjustable speed (0.5~6 m/min) for steady and accurate part movement.

✅ Variable Pressure & Speed Control: Easily adjust sanding pressure, belt speed, and conveyor speed to process different materials and thicknesses.

✅ High-Precision Thickness Adjustment: Smooth mechanical or servo adjustment with fine accuracy (±0.01mm), suitable for sheet thickness from 0.8mm to 80mm.

✅ Industrial Filtration Ready: Compatible with water circulation filtration systems for environmentally friendly, low-maintenance operation.

Suitable Applications:

Deburring and slag removal after laser cutting, plasma cutting, and flame cutting.

Oxide layer removal on carbon steel and stainless steel.

Edge smoothing and rounding for safety and functionality.

Hairline and satin finishing on stainless steel panels.

Pre-coating or pre-painting surface preparation.

Technical Specifications (Example):

| Specification | Unit | RR1300 |

| Max Working Width | mm | 1300 |

| Working Thickness Range | mm | 0.8 - 80 |

| Min Workpiece Size | mm | 50×50 |

| Conveyor Speed | m/min | 0.5 - 6 (adjustable) |

| Abrasive Belt Size | mm | 1910×1300 |

| Sanding Head Power | kW | 22-30 kW (per head) |

| Total Installed Power | kW | ~40-50 kW |

| Sanding Stations | - | 1 or 2 wide belt heads |

| Cooling Method | - | Wet sanding (water cooling) |

| Machine Weight | kg | Approx. 3500 - 4000 kg |

Key Advantages of RR1300:

✅ Process Large Parts Quickly: Suitable for large plates and panels with high throughput.

✅ One-Pass Multi-Purpose Processing: Combines deburring, edge rounding, slag removal, and surface finishing in one cycle.

✅ Cool, Clean Operation: Wet sanding keeps parts cool, prevents oxidation, and minimizes dust.

✅ Consistent, High-Quality Finish: Uniform results with reduced manual rework and higher surface precision.

✅ Durable Industrial Build: Low maintenance, high reliability, and long service life for 24/7 factory operation.

Optional Upgrades:

Additional rotary brush units for enhanced edge rounding (up to 2mm radius).

PLC touchscreen controls with recipe storage for quick setup.

Vacuum conveyor table for processing small parts.

Closed-loop water filtration systems for efficient recycling and reduced water consumption.