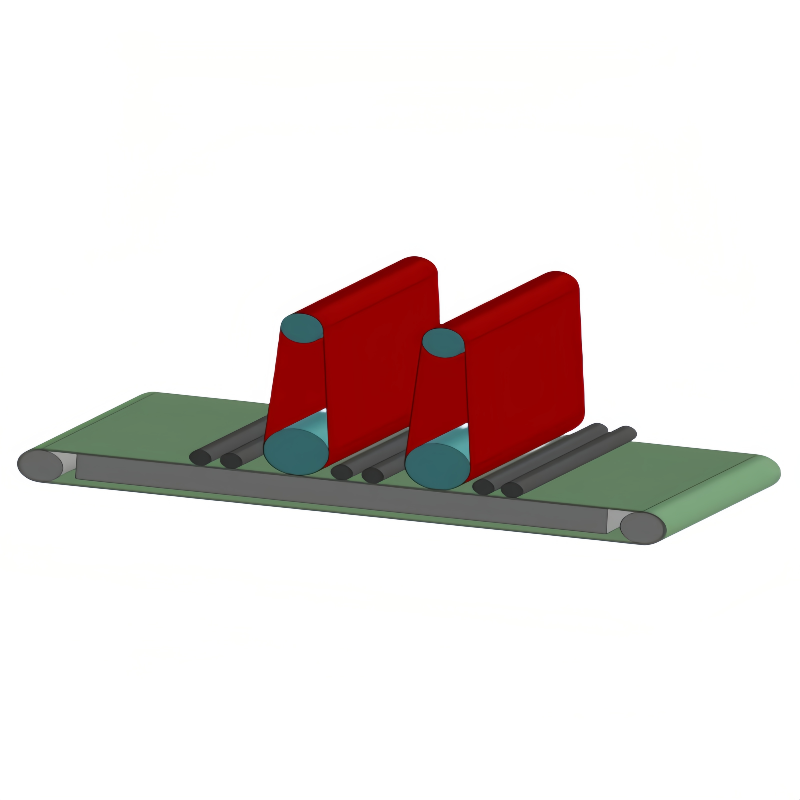

✅ RR5240 400mm Wet Wide Belt Sander – Product Overview

The RR5240 Wet Wide-Belt Sander is a high-performance industrial grinding and finishing machine designed for the deburring, slag/dross removal, oxide skin removal, edge rounding, and surface finishing of metal sheets and parts. With a 400mm working width, this machine features two sanding heads working under a water bath system, which provides effective cooling and dust suppression during processing.

This model is especially suitable for heat-sensitive materials like stainless steel, thin metal sheets, aluminum, and mixed metals, preventing deformation and discoloration during grinding or polishing.

✅ Key Features & Advantages

✅ Two High-Powered Sanding Stations: Equipped with two sanding heads, the RR5240 delivers superior deburring and surface conditioning in a single pass.

✅ Water Bath Process: Full water circulation reduces heat, prevents workpiece distortion, and minimizes dust and sparks.

✅ Ideal for Heat-Sensitive Materials: Excellent for processing stainless steel, thin metals, and soft non-ferrous alloys without risk of burning or warping.

✅ Heavy-Duty Industrial Design: Robust frame structure ensures stable and vibration-free operation, improving processing precision.

✅ Consistent Finishing Quality: Achieves uniform surface textures from coarse grinding to fine graining finishes.

✅ Minimal Consumable Cost: Wet grinding reduces abrasive belt wear and extends consumable life.

✅ Optional Magnetic Worktable: Securely holds magnetic materials during processing, allowing for precise handling of small or thin parts.

✅ User-Friendly Operation: Intuitive controls, adjustable conveyor speed, and easy maintenance access reduce labor training requirements.

✅ Machine Functions

Deburring: Efficient removal of burrs left after laser cutting, punching, or shearing processes.

Slag & Dross Removal: Effective in removing slag and dross from plasma or flame-cut components.

Oxide Removal: Strips oxide layers and discoloration from cut edges, improving further processing like welding or painting.

Surface Conditioning: Prepares surfaces for downstream processes such as coating, welding, or assembly.

Edge Rounding: Light edge rounding effect with fine abrasive belts to improve part safety and coating adhesion.

Brushing Finish (Optional): With additional brushing units, the machine can achieve decorative finishes like satin or hairline textures (if required in customized configurations).

✅ Technical Specifications

| Model | RR5240 |

| Max Working Width | 400 mm |

| Max Working Height | 60 mm |

| Min Working Length | 150 mm |

| Number of Heads | 2 (two sanding heads) |

| Sanding Belt Size | 1900 mm × 400 mm |

| Main Motor Power | 7.5 kW per sanding head |

| Total Installed Power | ~17 kW |

| Feeding Speed | Adjustable, 0.5 – 6 m/min |

| Abrasive Belt Speed | ~12 m/s |

| Water Cooling System | Included – full water circulation with filters |

| Worktable Type | Conveyor belt, optional magnetic table |

| Machine Dimensions | 2400 mm (L) × 1450 mm (W) × 1800 mm (H) |

| Machine Weight | ~1800 kg |

| Dust Collection | Water bath filtration, minimal external dust collection required |

✅ Typical Applications

✅ Industrial Sectors:

Sheet Metal Processing

Stainless Steel Fabrication

Laser and Plasma Cutting Workshops

Kitchenware and Appliance Industry

Automotive Components Manufacturing

Metal Furniture Production

Architectural Metalwork

General Metal Processing Workshops

✅ Workpiece Types:

Laser cut metal parts

Stamped and punched parts

Thin stainless steel plates

Non-ferrous metal sheets (aluminum, copper)

Mixed metal components

Precision components requiring oxide removal and surface uniformity

✅ Summary

The RR5240 Wet Wide-Belt Sander is an ideal universal machine for manufacturers seeking a compact yet powerful solution for deburring, slag removal, oxide cleaning, and surface finishing—especially when working with stainless steel or thin sheets. Its water-cooled process protects sensitive materials from deformation, guarantees a burr-free, clean surface finish, and reduces downstream processing costs.

Thanks to its robust construction, high efficiency, and easy operation, the RR5240 provides reliable 24/7 production capability with low operational costs. It is the perfect choice for fabricators and metalworking companies aiming to improve product quality, reduce manual labor, and increase overall production efficiency.