✅ RR5240C Wet Metal Wide Belt Sander | Magnetic Conveyor | Dual Sanding Heads

Product Overview:

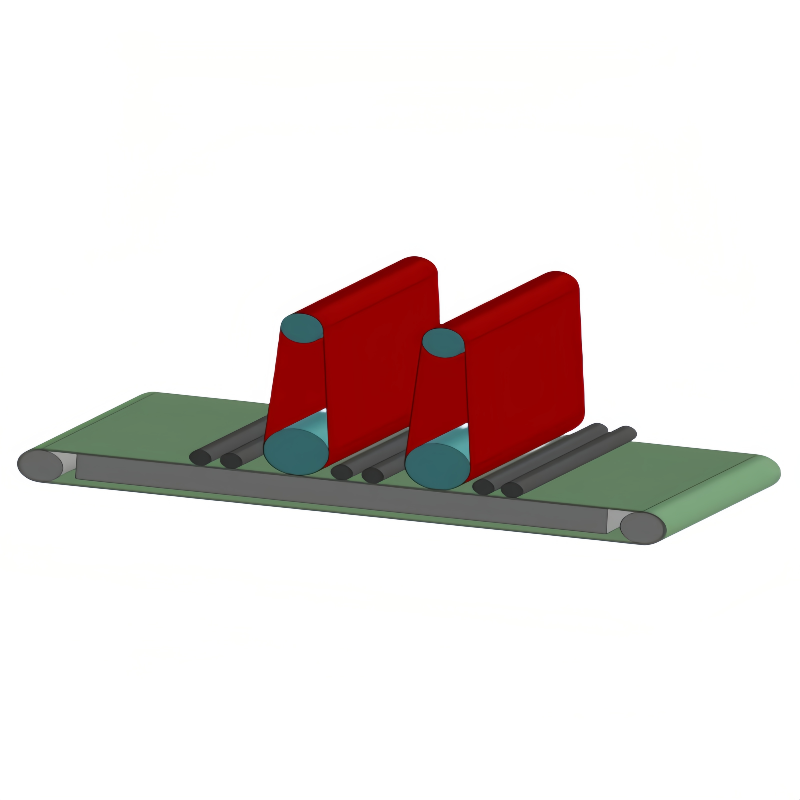

The RR5240C Wet Metal Wide Belt Sander is a professional industrial-grade machine designed for high-efficiency deburring, dross and slag removal, oxide layer removal, edge rounding, and surface finishing of metal sheets and small components. Equipped with a 400mm working width, two sanding heads, and a magnetic conveyor system, this model offers stable, consistent performance in demanding metalworking environments.

Its water-cooling (wet grinding) system ensures that even thin and heat-sensitive materials such as stainless steel can be processed without deformation or discoloration. The magnetic worktable provides superior holding power for small magnetic metal parts, ensuring accuracy and safety during operation.

This machine is particularly suitable for laser-cut, plasma-cut, and punched parts, making it an ideal solution for sheet metal workshops, fabrication shops, and metal part manufacturers.

✅ Key Features:

Wet Grinding System: Continuous water flow cools workpieces, reduces dust, extends abrasive belt life, and prevents overheating or discoloration.

Magnetic Conveyor Table: Securely holds thin or small ferrous metal parts in place during sanding to avoid shifting or tipping.

Dual Sanding Stations: Two high-performance sanding heads efficiently complete deburring and surface finishing in one pass.

400mm Working Width: Perfect for medium and small-sized sheet metal parts.

Industrial Robust Design: Heavy-duty construction guarantees stable operation under continuous working conditions.

Energy-Efficient Motors: Equipped with energy-saving motors that deliver high torque for precise grinding.

Adjustable Feed Speed: Conveyor speed can be adjusted to meet different surface finishing requirements.

Simple Operation: Intuitive user controls with easy belt change system minimize downtime and maximize productivity.

Low Consumable Costs: Water-cooled belts last longer and require fewer replacements compared to dry sanding.

Compact Footprint: Space-saving design suitable for small workshops or limited production spaces.

✅ Functions:

Deburring: Quickly removes sharp burrs and edges from laser, plasma, or punching processes.

Slag/Dross Removal: Effectively cleans up slag from plasma or flame-cut parts.

Oxide Removal: Cleans oxidation from steel parts to improve coating adhesion.

Surface Finishing: Provides a smooth, consistent surface ready for painting, welding, or further processing.

Edge Rounding: Achieves slight edge rounding for safer handling and better surface treatment performance.

Graining / Satin Finish (optional belts): Suitable for creating decorative finishes like hairline or satin surface.

✅ Technical Specifications:

| Parameter | RR5240C Specification |

| Max Working Width | 400 mm |

| Max Working Thickness | 60 mm |

| Min Working Length | 150 mm |

| Number of Stations | 2 (Two Sanding Heads) |

| Sanding Belt Size | 1900 mm × 400 mm |

| First Sanding Head Power | 7.5 kW |

| Second Sanding Head Power | 7.5 kW |

| Feeding Conveyor Power | 1.5 kW |

| Lifting Motor Power | 0.37 kW |

| Total Installed Power | Approximately 18 kW |

| Belt Line Speed | 12 m/s |

| Conveyor Speed | 0.5–6 m/min (adjustable) |

| Cooling System | Full Water Bath Circulation System |

| Conveyor Type | Magnetic Conveyor Belt |

| Machine Dimensions (L×W×H) | 2400 × 1450 × 1800 mm |

| Net Weight | Approx. 1800 kg |

✅ Typical Applications:

Deburring laser-cut stainless steel sheets and parts

Removing slag and dross from flame-cut and plasma-cut metal parts

Cleaning oxidation layers from steel components

Surface smoothing before painting or welding

Edge rounding of sheet metal parts for improved coating durability

Pre-finishing and graining applications for decorative panels

✅ Common Industrial Uses:

Sheet Metal Processing Workshops

Stainless Steel Fabrication Plants

Laser Cutting Job Shops

Automotive Parts Manufacturing

Elevator Panel Finishing

Kitchenware and Bathroom Fixture Production

Architectural Metal Industry

General Metalworking and Fabrication

✅ Summary:

The RR5240C Wet Wide Belt Sander with Magnetic Conveyor is a multi-functional solution for improving product quality, reducing labor time, and streamlining production processes in metalworking industries. It is highly recommended for workshops seeking high-speed deburring, precise oxide removal, and consistent surface finishing, especially for small to medium-sized metal parts.