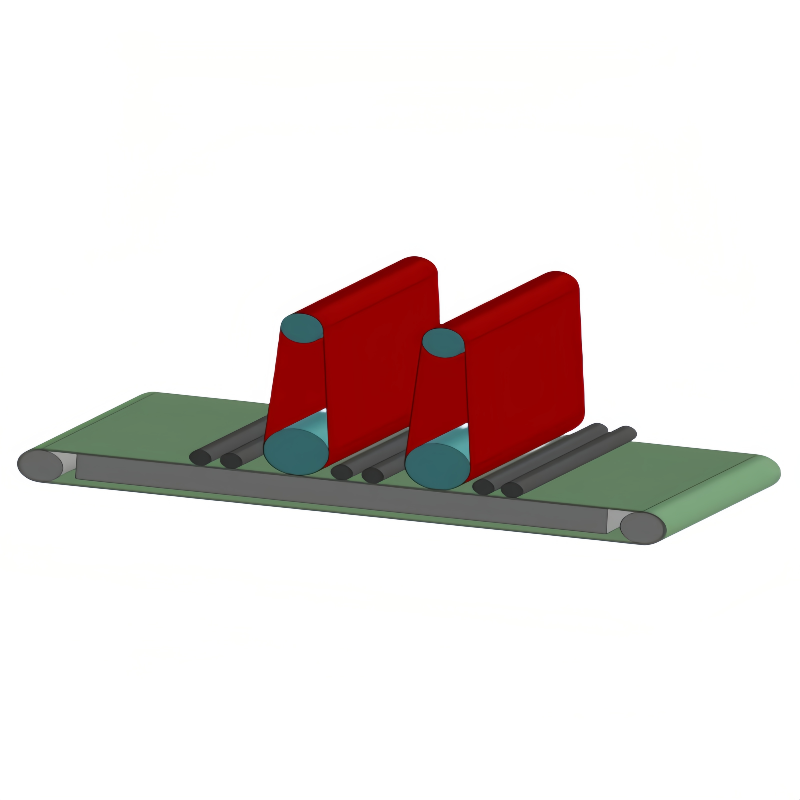

RR630 Series Metal Wide Belt Sander

The RR630 Series Metal Wide Belt Sander is a versatile and high-performance machine designed for deburring, deslagging, edge rounding, and surface finishing of metal parts. With a maximum working width of 630mm and robust power configurations, the RR630 series delivers reliable results for various metal processing industries including sheet metal fabrication, laser cutting, plasma cutting, and metal polishing.

Models and Specifications

| Parameters | Unit | RR630 | RP630 | RRR630 | RRP630 |

| Max Working Width | mm | 630 | 630 | 630 | 630 |

| Max Working Height | mm | 60 | 60 | 60 | 60 |

| Min Working Length | mm | 220 | 220 | 220 | 220 |

| First Sand Belt Power | kW | 15 | 15 | 15 | 15 |

| Second Sand Belt Power | kW | 11 | / | 11 | 11 |

| Third Sand Belt Power | kW | / | / | 11 | / |

| Polishing Wheel Power | kW | / | 11 | / | 11 |

| Rotation Motor Power | kW | / | / | / | / |

| Feeding Motor Power | kW | 1.5 | 1.5 | 2.2 | 2.2 |

| Lifting Motor Power | kW | 0.37 | 0.37 | 0.37 | 0.37 |

| Oscillating Motor Power | kW | / | 1.5 | / | 1.5 |

| Vacuum Motor Power | kW | / | / | / | / |

| Machine Size (L×W×H) | m | 2.1×1.9×2 | 2.1×1.9×2 | 2.4×1.9×2 | 2.4×1.9×2 |

| Machine Weight | kg | 1600 | 1600 | 1800 | 1800 |

| Abrasive Belt Size | mm | 1900×630 | 1900×630 | 1900×630 | 1900×630 |

Key Features of RR630 Series

✅ Multiple Sanding Configurations:

Choose from single, double, or triple sanding belts, and optional polishing wheels to meet specific finishing needs.

✅ Powerful Motors:

Equipped with 15kW main sanding motors, ensuring stable, high-efficiency performance, capable of handling both small parts and heavy-duty plates.

✅ Adjustable Feed Speed and Thickness Control:

Flexible feeding system with precise height adjustment, making it suitable for thin sheets, small pieces, and larger industrial parts.

✅ Heavy-Duty Construction:

Industrial-grade steel frame and components guarantee long lifespan, stability, and minimal vibration during operation.

✅ Compact Footprint:

Space-saving design with small footprint, suitable for small workshops or large manufacturing facilities alike.

Applications and Uses

The RR630 Series Wide Belt Sander is widely used in:

Deburring laser-cut metal sheets

Edge rounding and smoothing of punched parts

Removing oxide layers after plasma or flame cutting

Surface finishing for stainless steel, carbon steel, and aluminum plates

Slag removal after welding and flame cutting

Achieving uniform surface roughness prior to coating or painting

Light polishing and brushing of decorative metals

Whether you are a sheet metal fabricator, laser cutting workshop, or a metal furniture manufacturer, the RR630 Series ensures consistent surface quality, improved productivity, and reduced manual labor costs.

Why Choose RR630 Wide Belt Sander?

✔️ High Production Efficiency

✔️ Superior Surface Quality

✔️ Reduced Manual Finishing Time

✔️ Robust Structure, Low Maintenance

✔️ Customizable Configurations

Common Industries Served

Metal Fabrication

Sheet Metal Manufacturing

Automotive Parts Processing

Kitchenware and Home Appliance Industry

Architectural Metalwork

Aerospace Metal Finishing

Mechanical Equipment Production