RR630 Series Metal Wide Belt Sander

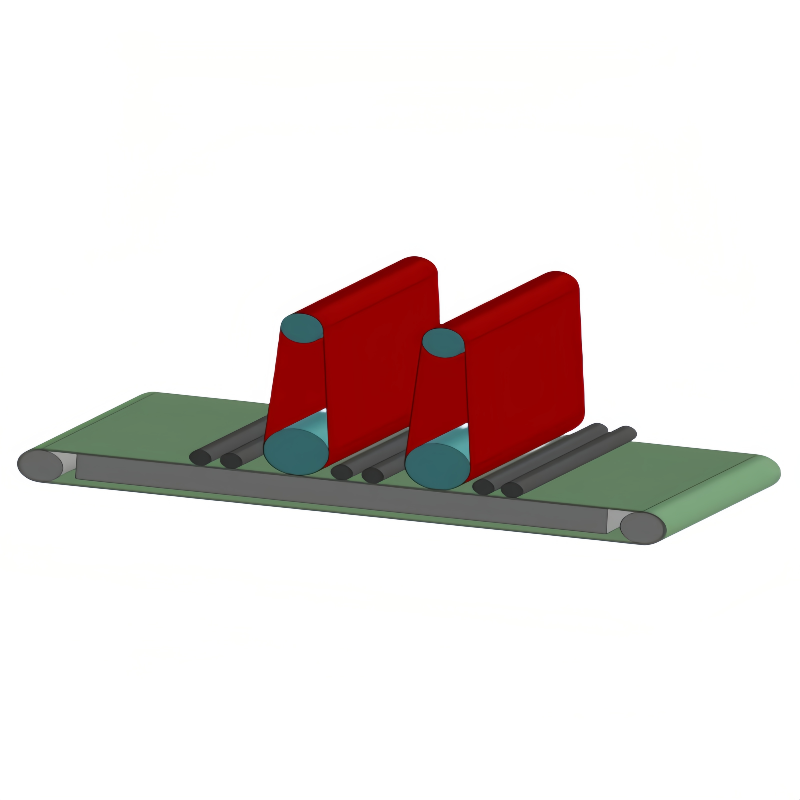

RR630 Wide Belt Sander / Industrial Belt Grinder

High-Performance Industrial Sander for Metal Deburring & Surface Finishing

The RR630 is a robust and efficient industrial wide belt sander designed for deburring, surface grinding, and finishing of flat metal sheets and fabricated components. With a working width of up to 630mm, the RR630 is ideal for medium to large-sized workpieces and supports both light and heavy-duty grinding operations across a wide range of materials including stainless steel, carbon steel, aluminum, and non-ferrous metals.

✅ Key Features:

Model: RR630

Working Width: 630mm

Abrasive Belt Size: Typically 2000–2200mm length (customizable)

Multi-head Configuration: Available with single or dual sanding stations (belt + brush optional)

Heavy-Duty Frame: Ensures vibration-free and stable grinding

Dry or Wet Type: Optional water cooling system for heat-sensitive applications

Variable Feed Speed: Adjustable conveyor speed for precise control over material removal

Easy Belt Change System: Quick replacement of abrasives improves operational efficiency

Precision Bed Height Adjustment: For consistent grinding results

⚙️ Typical Technical Specifications (Example Configuration):

| Parameter | Value |

| Max. Working Width | 630mm |

| Max. Working Height | 60mm |

| Min. Workpiece Size | 50mm x 50mm |

| Main Motor Power | 11–15 kW (depends on head config) |

| Feeding Motor Power | 1.5–2.2 kW |

| Belt Speed | 15–30 m/s (adjustable) |

| Feed Speed | 0.5–6 m/min (adjustable) |

| Machine Dimensions | Approx. 2400 × 1600 × 2000 mm |

| Machine Weight | ~2000–3000 kg |

️ Applications:

Deburring of laser/plasma/flame-cut parts

Grinding of weld seams and rough surfaces

Edge smoothing and radius rounding

Pre-finishing for powder coating or painting

Brushed or satin finishing of stainless steel panels

Used in metal fabrication, kitchenware, elevator panels, automotive parts, and machinery manufacturing

Advantages:

Wide processing width up to 630mm

Uniform, high-quality surface results with adjustable grinding pressure

Durable construction for continuous industrial use

Low operating cost, high efficiency, and reduced rework

Flexible configurations for custom processing needs