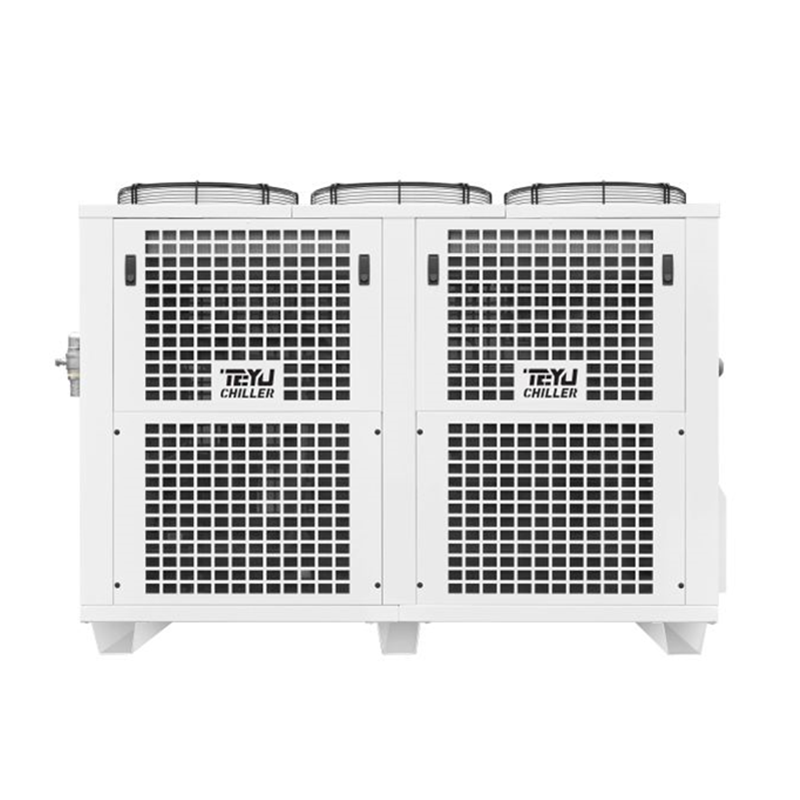

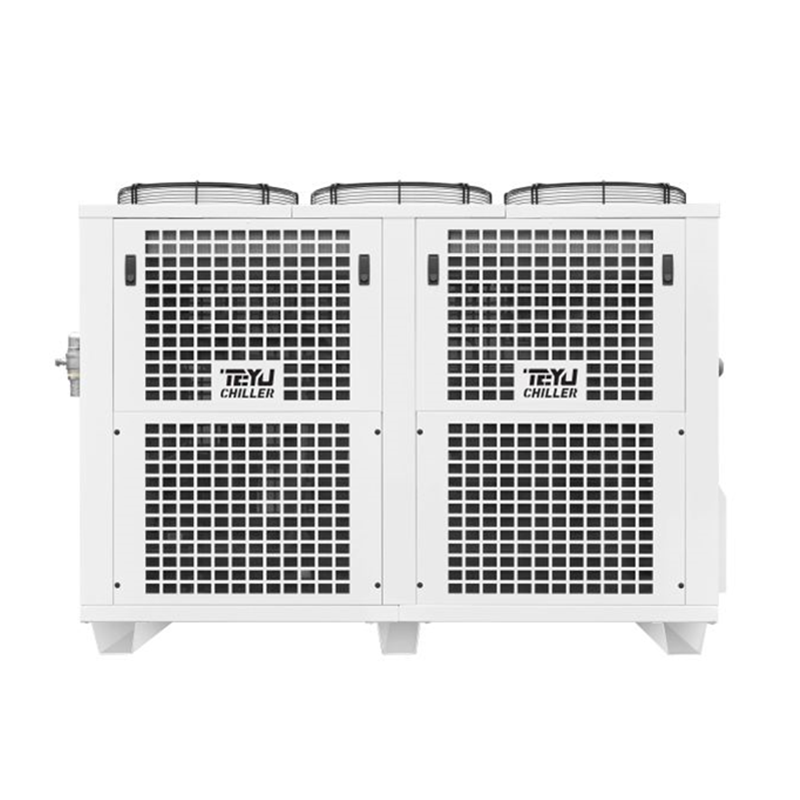

CWFL-30000 High-Power Fiber Laser Chiller

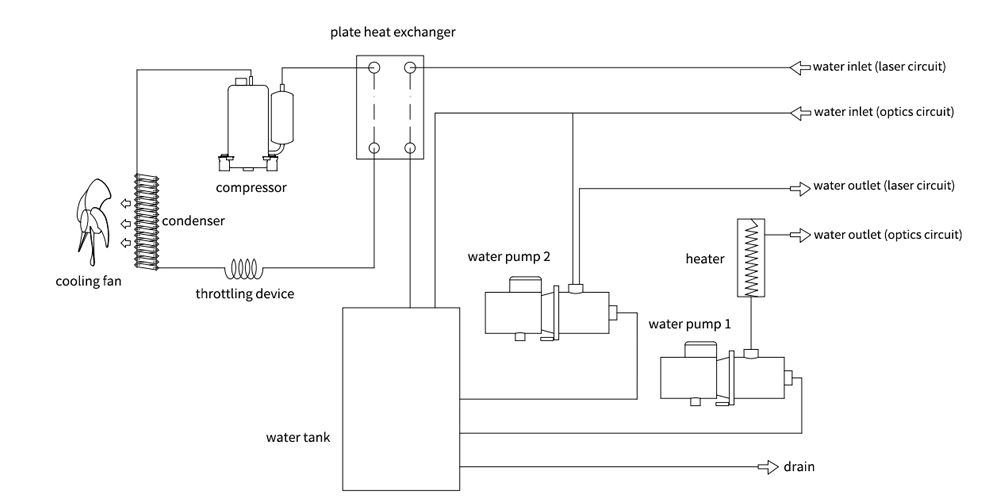

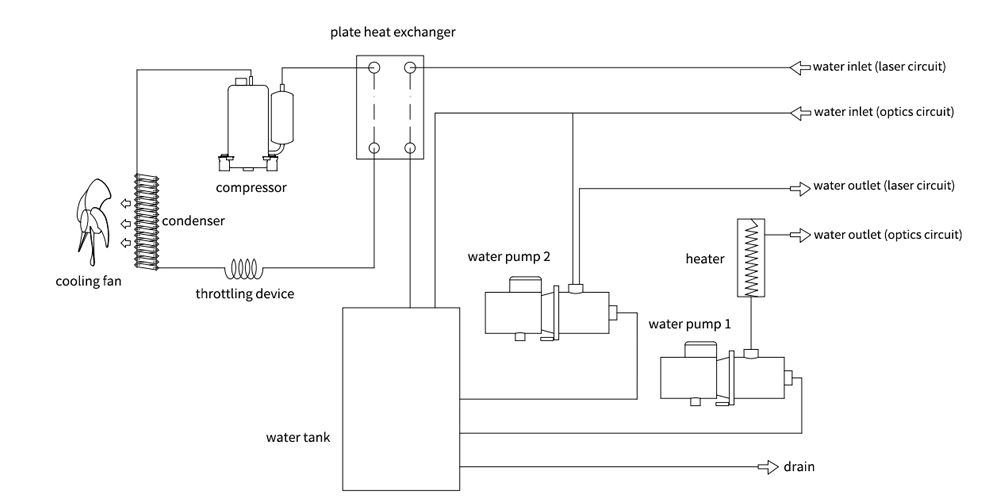

Product Overview: The CWFL-30000 chiller is designed for cooling 30,000W fiber laser cutting equipment. It features two independent temperature control systems to separately manage high and low temperatures, ensuring efficient cooling of both the laser and the laser head. The chiller supports dual temperature control modes and is compatible with various brands of high-power laser cutting machines.

Main Features of CWFL-30000 Fiber Laser Chiller

Temperature Control Precision: ±1℃

Eco-friendly Refrigerants: Optional

ModBus-485 Communication: Supports various settings and fault display functions

Multiple Alarm Protections: Includes compressor delay protection, compressor overcurrent protection, water flow alarm, high/low temperature alarm

Multi-country Power Specifications: ISO9001, CE, RoHS, REACH certified

Optional Accessories: Heater and water purification system available

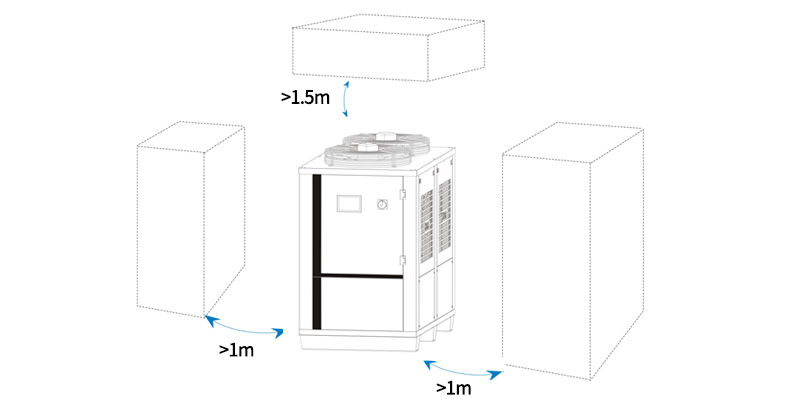

Convenient Maintenance: Side panels use a snap-in design for easy removal and dust filter cleaning

Product Specifications

| Model | CWFL-30000ET | CWFL-30000FT |

| Working Voltage | AC 3P 380V | AC 3P 380V |

| Working Frequency | 50Hz | 60Hz |

| Working Current | 10.6~61.2A | 7.9~62.5A |

| Max. Power Consumption | 27.62kW | 25.66kW |

| Heater Power | 1800W + 5400W | 1800W + 10800W |

| Temperature Control Precision | ±1℃ | ±1℃ |

| Reducer | Capillary | Capillary |

| Pump Power | 3.5kW | 5.5kW |

| Tank Capacity | 250L | 330L |

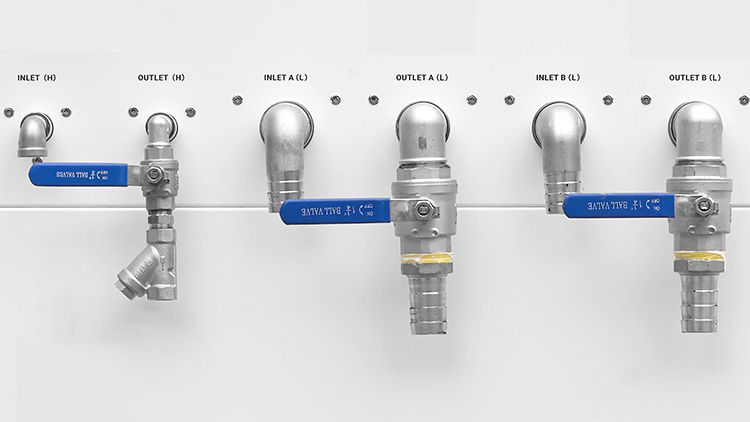

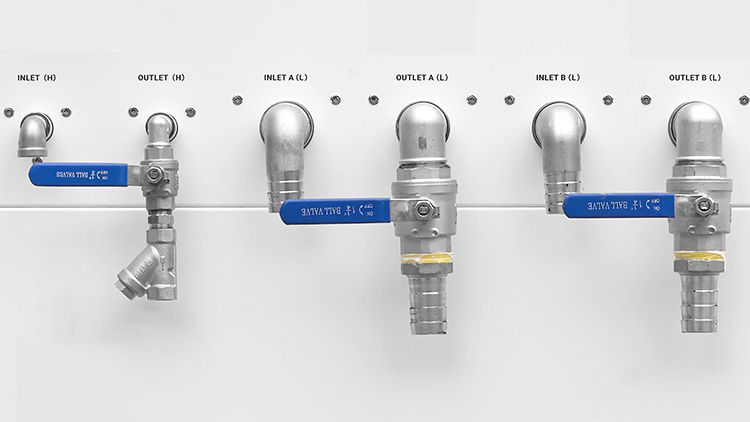

| Inlet and Outlet | Rp1/2” + Rp1-1/4” | Rp1/2” + Rp2” |

| Max. Pump Pressure | 85M | 80M |

| Rated Flow | 10L/min + >250L/min | 10L/min + >250L/min |

| Net Weight | 540Kg | 737Kg |

| Gross Weight | 710Kg | 966Kg |

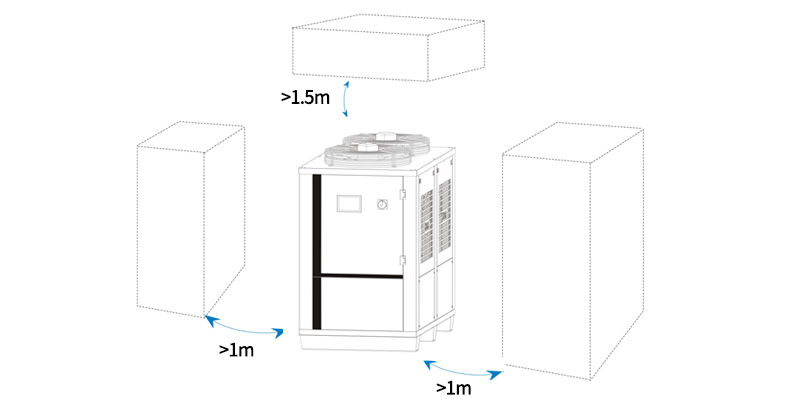

| Machine Dimensions | 207 x 96 x 146 cm (L x W x H) | 227 x 113 x 190 cm (L x W x H) |

| Package Dimensions | 229 x 120 x 175 cm (L x W x H) | 235 x 137 x 214 cm (L x W x H) |

Note: The technical parameters listed are for reference only; actual delivery will be based on final specifications.

Advantages of CWFL-30000

Extended Service Life: Durable and long-lasting.

Reliable Cooling Performance: Provides stable cooling for high-power lasers.

Eco-friendly and Energy-efficient: Designed to be environmentally friendly and cost-effective.

Intelligent Control System: Features advanced temperature control with two modes.

Wide Range of Models: Over 90 standard models and 120 custom options available, suitable for more than 100 manufacturing industries.

Experienced Support Team: 22 years of expertise with a dedicated R&D team.

Functional Design

Dual Temperature Control Modes: Easily switch between constant and intelligent temperature control.

High-Power Cooling: Supports ModBus-485 communication for advanced monitoring and control.

Convenient Maintenance: Snap-in side panels for easy access and cleaning of dust filters.