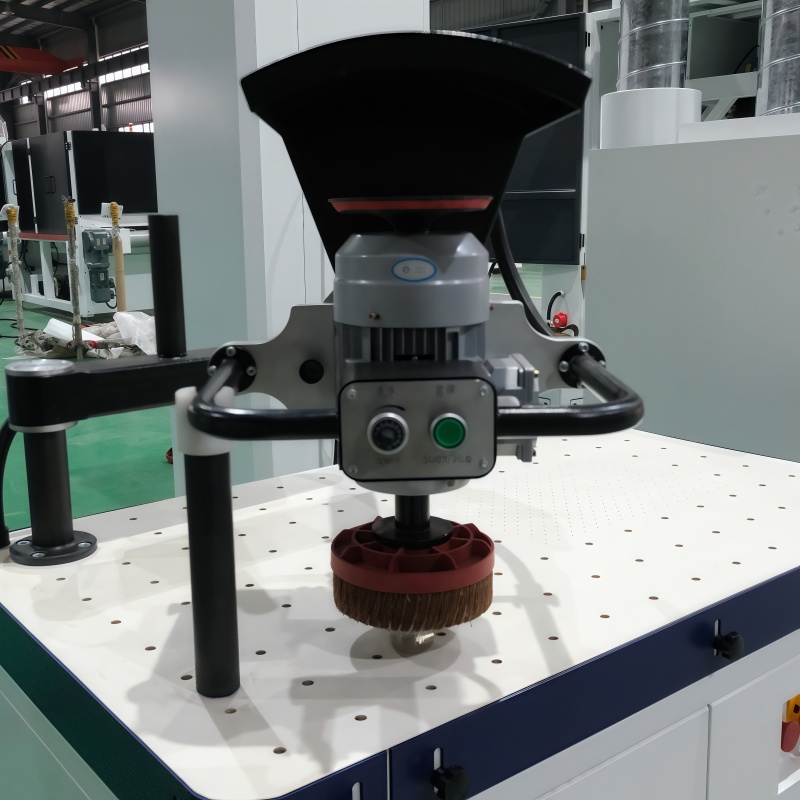

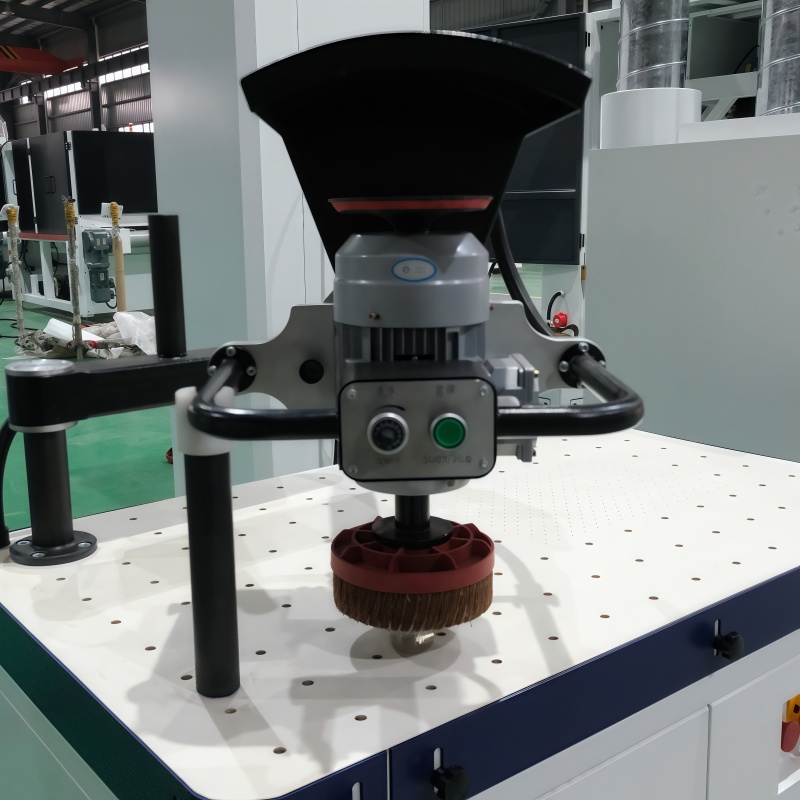

The LSD-162 Semi-Automatic Manual Edge Rounding Deburring Machine is designed for deburring and edge rounding applications, typically for metal parts that require smooth, rounded edges after processes like laser cutting, punching, or stamping. Here are some key features and capabilities of the LSD-162:

Key Features:

Semi-Automatic Operation: The machine combines manual setup with automatic operation, allowing for easy use while maintaining flexibility for various workpieces.

Edge Rounding: Equipped to round sharp edges of metal parts, typically with a radius between 0.2 to 2mm.

Deburring: Effectively removes burrs, oxidized layers, and other imperfections from the edges of metal parts.

Precision: Offers precise control over the deburring and edge rounding process, ensuring uniform results across multiple workpieces.

Wide Material Compatibility: Suitable for a variety of metals, including stainless steel, aluminum, and carbon steel.

Adjustable Settings: Adjustable working speed and pressure settings to accommodate different part sizes and material thicknesses.

Typical Applications:

Laser Cut Parts: Removes burrs from laser-cut edges and rounds sharp edges for safety and aesthetic purposes.

Stamped and Sheared Parts: Smoothens edges and removes burrs created during stamping or shearing.

General Deburring: Suitable for a range of industrial metalworking needs, particularly in industries like automotive, aerospace, and metal fabrication.

Benefits:

Enhanced Safety: By rounding sharp edges, the machine ensures that parts are safer to handle and use.

Improved Aesthetic: Provides a polished finish, enhancing the visual appeal of metal products.

Cost-Effective: Reduces the need for manual labor, saving on time and operational costs.

Flexible: Allows for easy adjustment to meet different part sizes and material requirements.