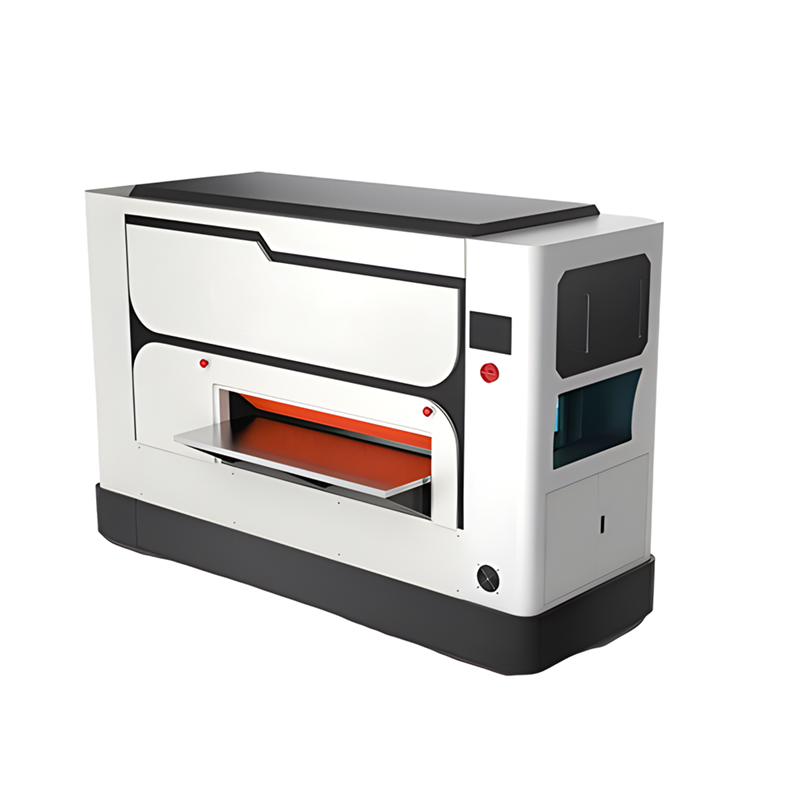

Precision Levelers | Plate & Sheet Metal Roller Levelers

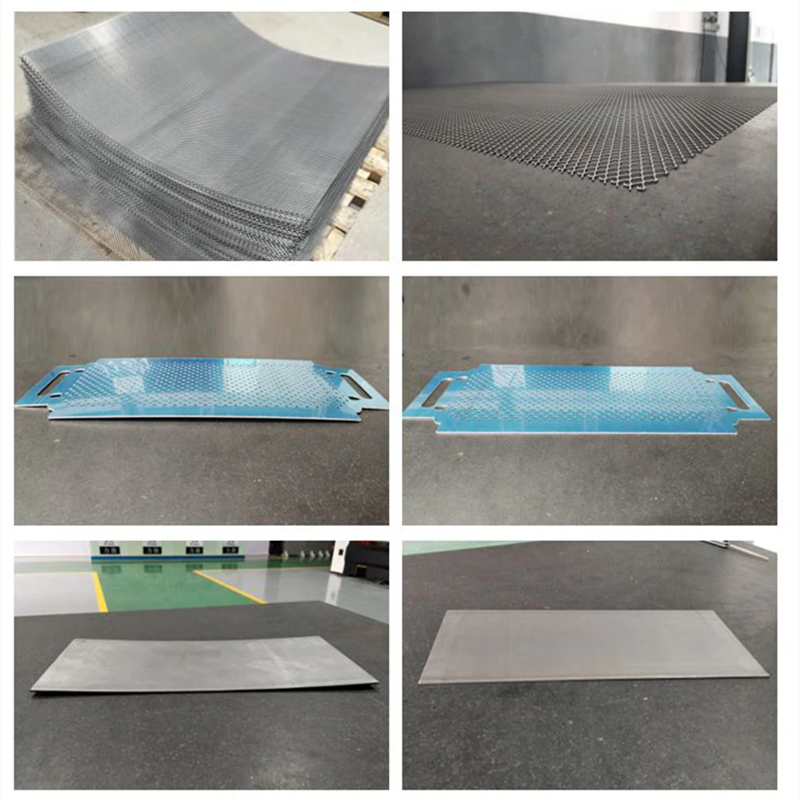

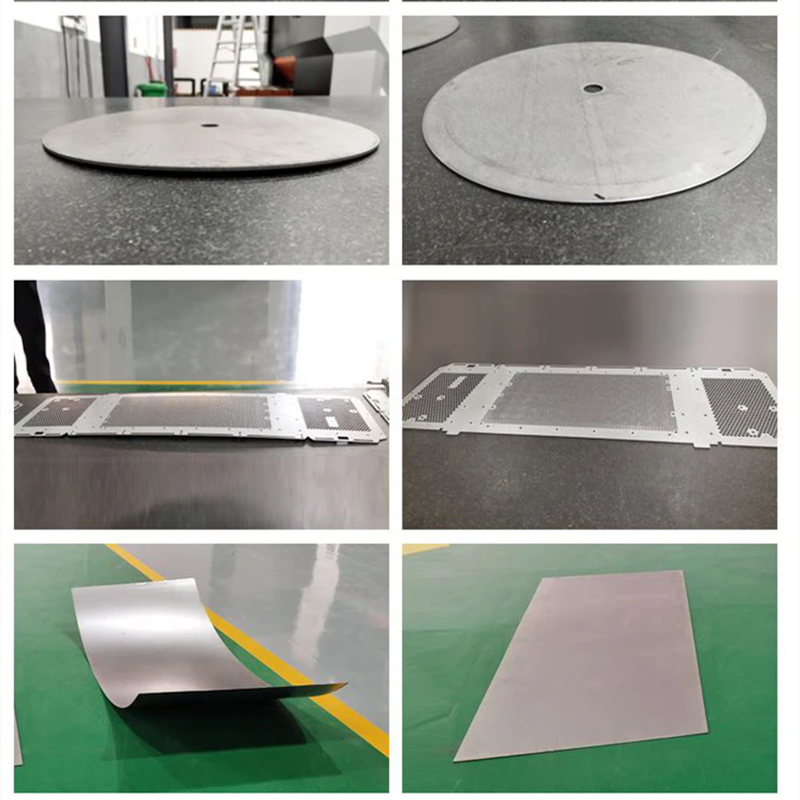

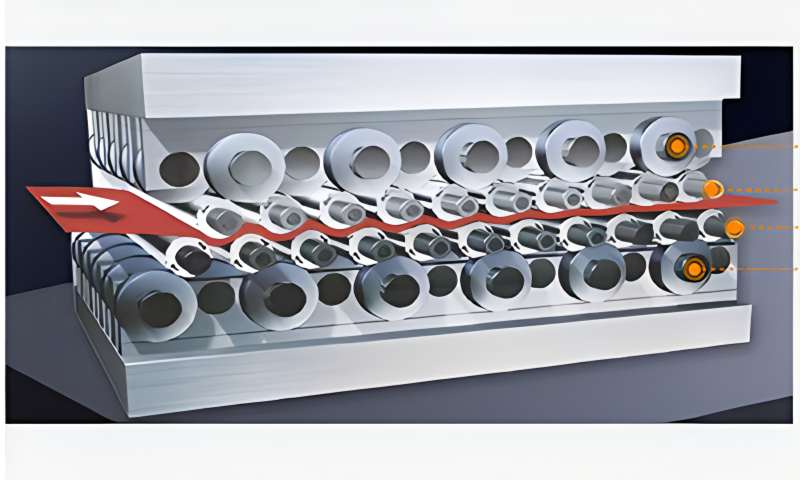

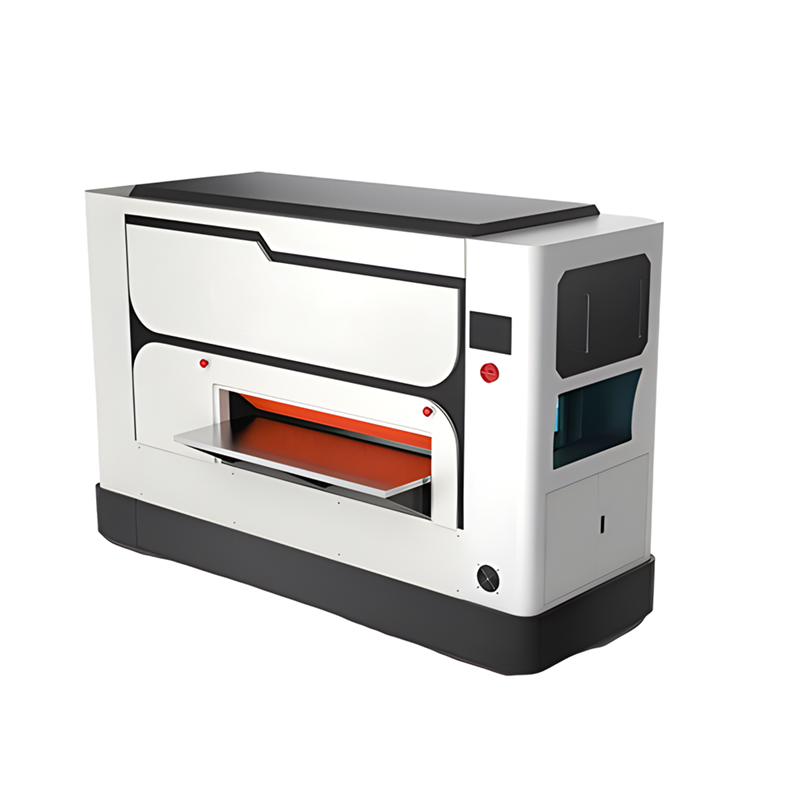

Precision Levelers are advanced machines designed to correct flatness imperfections in metal plates and sheet materials. These machines are critical in industries where precise flatness and quality of metal sheets and plates are essential, such as automotive, aerospace, construction, and manufacturing.

Key Features:

High Precision:

Variable Roller Configurations:

Automatic Adjustment:

Wide Range of Material Compatibility:

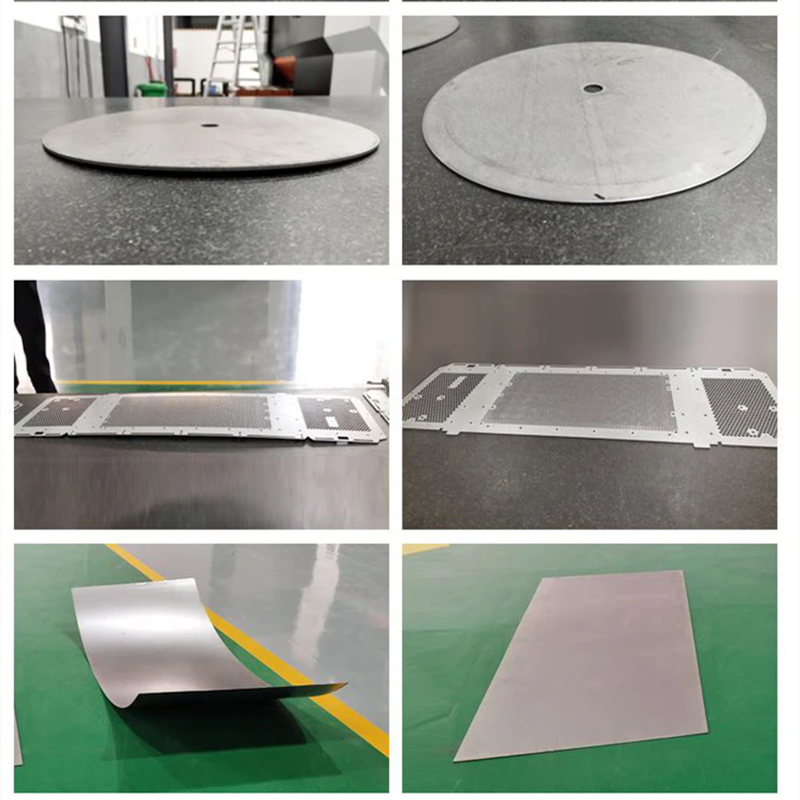

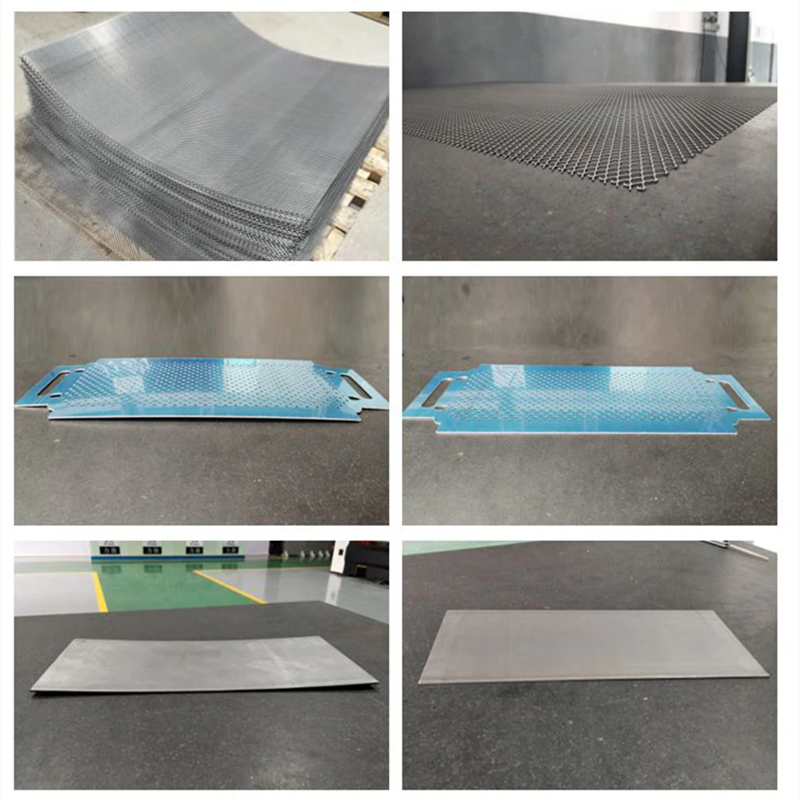

These machines can handle various materials, including steel, stainless steel, aluminum, copper, titanium, and other alloys. They are also effective for both thin sheets and thick plates.

Efficient Operation:

User-Friendly Controls:

Equipped with modern control systems, precision levelers allow operators to set and monitor parameters easily. Some machines come with touchscreens, allowing for easy adjustments and real-time monitoring.

Durability and Reliability:

Applications:

Automotive Industry: Leveling metal sheets and plates used in vehicle bodies, chassis components, and structural parts.

Aerospace Industry: Ensuring precise flatness for metal components used in aircraft and spacecraft manufacturing.

Construction Industry: Preparing flat metal sheets for structural components, facades, and decorative panels.

Manufacturing: Leveling materials for a wide range of products, from appliances to industrial equipment.

Shipbuilding: Ensuring flatness in large metal sheets used in ship hulls and decks.

HVAC Systems: Flattening metal sheets used in ductwork, ventilation, and other HVAC components.

Electrical Industry: Leveling metal sheets for enclosures, panels, and other electrical components.

Medical Equipment: Ensuring precise flatness in metal parts used in medical devices and machinery.

Types of Precision Levelers:

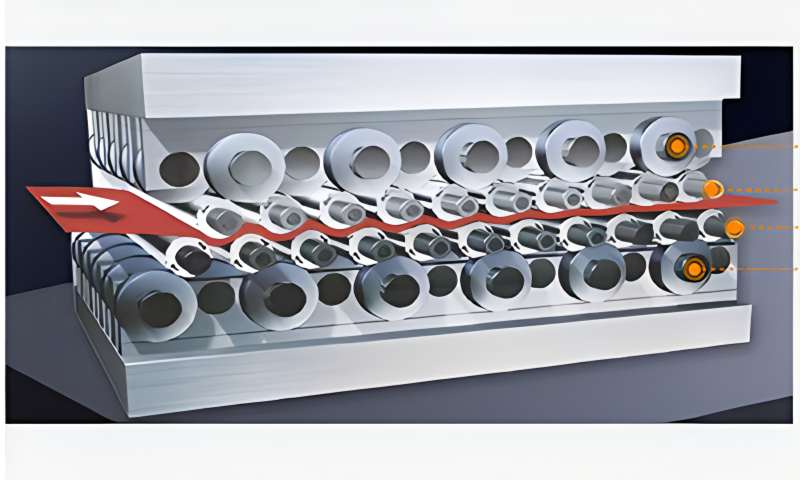

Plate Levelers:

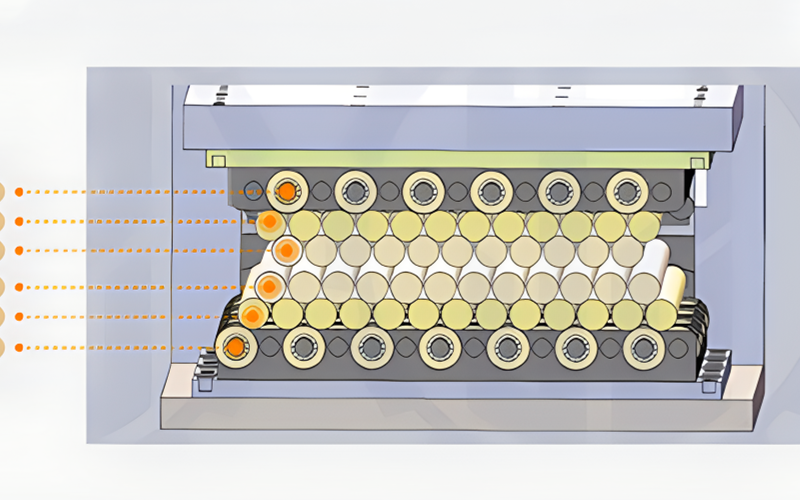

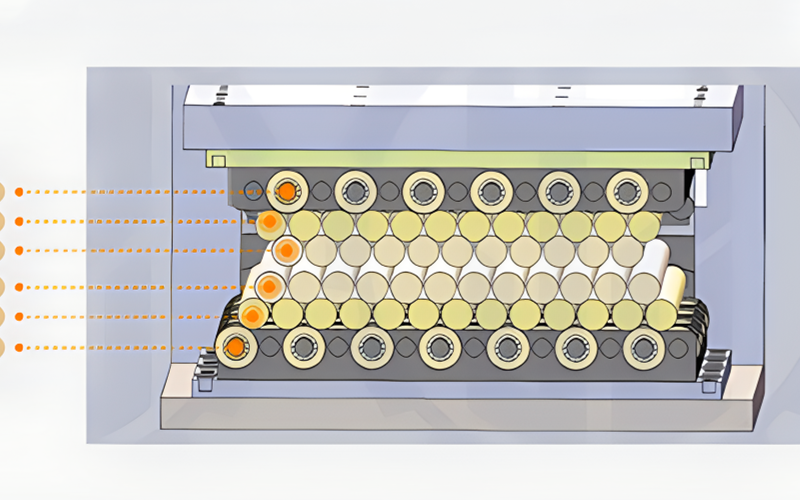

Sheet Metal Roller Levelers:

These levelers are optimized for thinner sheets of metal, ensuring smooth, flat surfaces ideal for manufacturing processes like stamping, forming, and cutting. They are widely used in the automotive and electronics industries.

High-Speed Precision Levelers:

Heavy-Duty Precision Levelers:

Advantages of Precision Levelers:

Improved Product Quality: Achieves precise flatness, which is crucial for downstream processes like welding, assembly, and coating.

Increased Efficiency: Reduces the need for manual correction of flatness, speeding up production and reducing labor costs.

Material Savings: Minimizes waste by ensuring that metal sheets and plates meet flatness requirements on the first pass.

Versatility: Capable of handling a wide range of materials and thicknesses, making them suitable for various industries.

Conclusion:

Precision levelers and plate & sheet metal roller levelers are essential tools in modern metalworking, providing the accuracy and efficiency needed to meet industry standards. Whether you're working with thin sheets or thick plates, these machines ensure that your metal materials are perfectly flat and ready for further processing, leading to higher quality products and increased productivity.