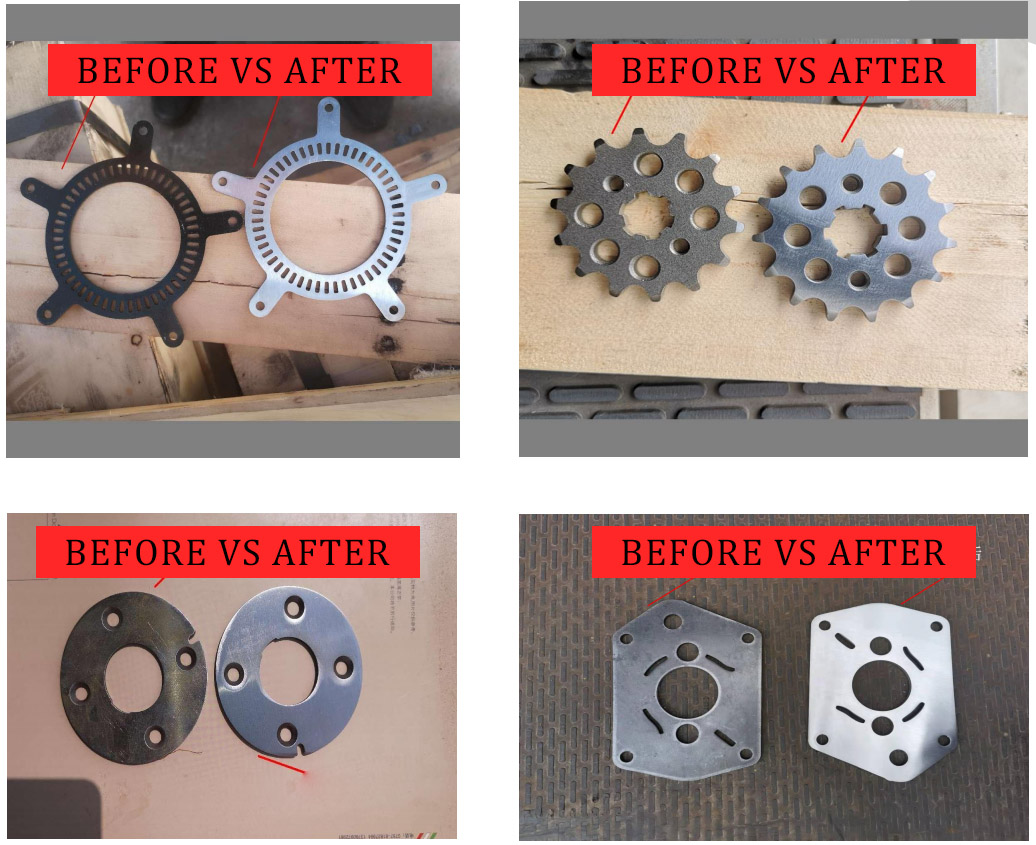

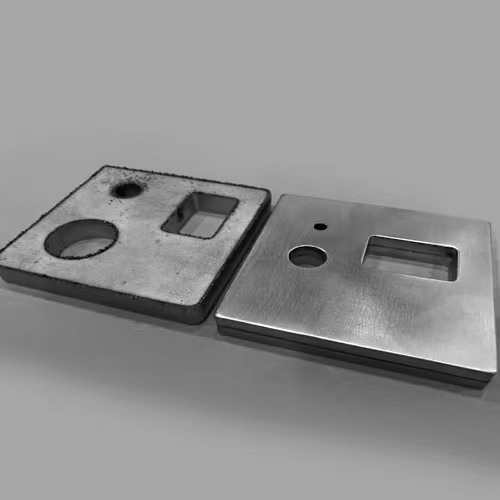

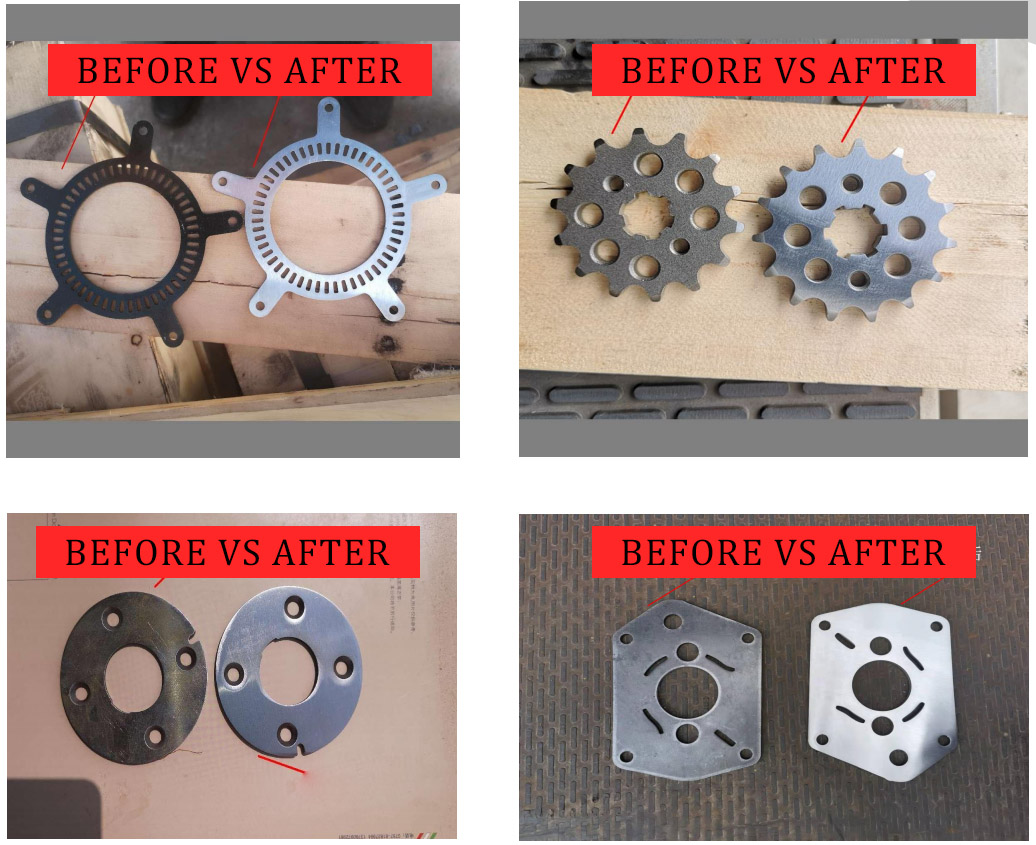

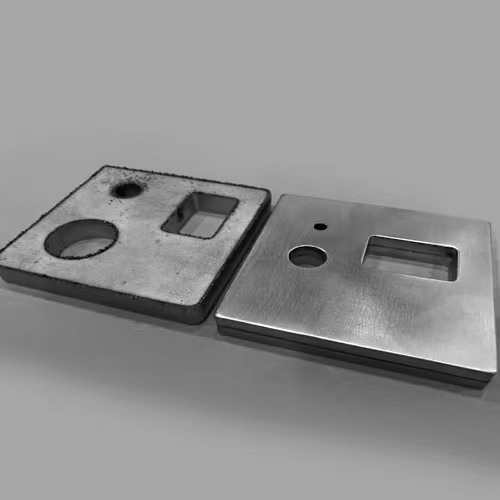

1. Deburring and rounding precision machining of internal and external contours. As it is a flexible machining process, all sheet metal parts that have undergone polishing, brushing, and film application treatment do not damage the surface or film coating.

2. Suitable for removing burrs from holes in sheet metal parts machined by CNC punching and shearing machines on equal or relatively identical planes; Remove burrs generated after laser cutting; Removal of slag generated by flame cutting or plasma cutting, etc.

3. Replace burrs with files, scrapers, or use electric or pneumatic tools for polishing process treatment to make the workpiece polished more evenly; More secure and effectively reducing labor costs to improve production efficiency.

4. Grinding and stroke parameter visualization can be freely adjusted, allowing only the contour and sharp edges of the workpiece to be polished without damaging the surface, effectively protecting the workpiece coating. It is suitable for workpieces with surface protection requirements such as galvanized sheet, coated aluminum sheet, copper sheet, stainless steel sheet, etc.

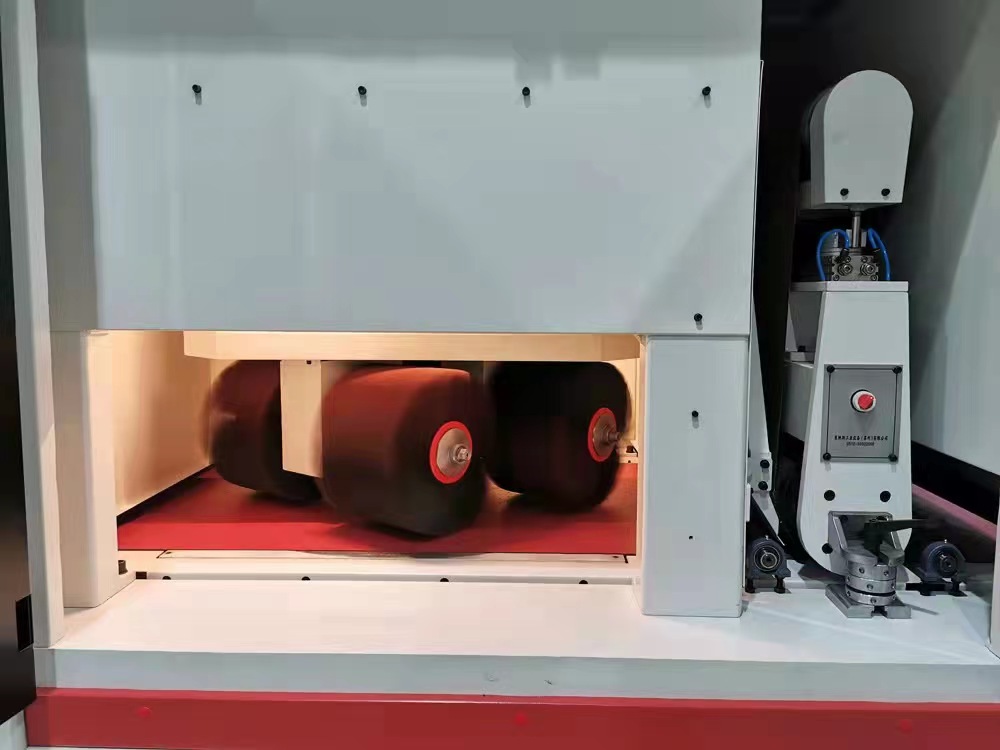

5. By using turbo vacuum adsorption technology, the workpiece is firmly adsorbed during polishing, greatly improving the processing range and efficiency.

6. The equipment adopts a PLC control system, which is easy to operate and convenient to adjust the polishing amount quickly and conveniently.

7. This machine uses universal consumables on the market, and can also be customized with imported sanding wheels to improve production efficiency and meet special product requirements.

8. The equipment has an interface for installing dust collectors, which can remove dust, metal shavings, and dust generated during the operation of the equipment. Separate dust removal equipment or existing equipment in the factory can be selected.

| item | value |

| Condition | New |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

| Warranty of core components | 1 Year |

| Core Components | Engine, Bearing |

| 20 |

| 1500 |

| Key Selling Points | Multifunctional |

| Warranty | 1 Year |

| Applicable Industries | Manufacturing Plant, Energy & Mining |

| Showroom Location | None |

| Product name | Metal Polishing Machine |

| Usage | Workpieces Surface Deburring Polishing |

| Application | Metal Workpiece |

| Machine Type | Automatic Grinding Polishing |

| Voltage | 380V 50Hz 3Phase/Customized |

| Speed | Adjusted |

| Polishing effect | Matt Finishing Hairline Finishing |

| Feature | High Effienciey |