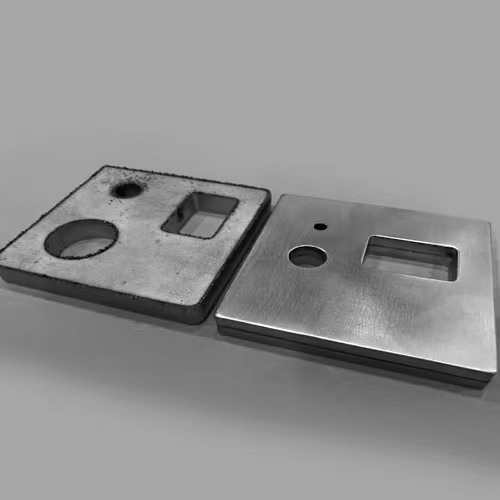

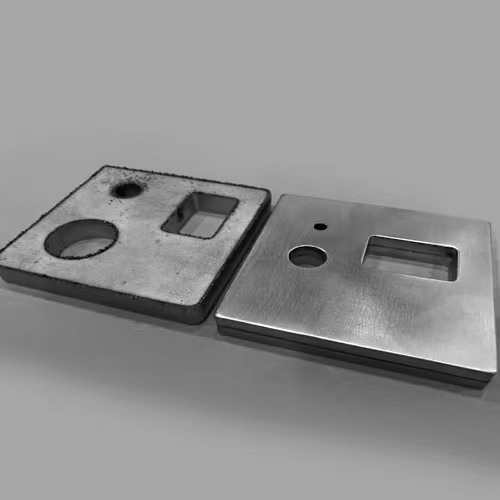

The deburring machine, also known as the metal sanding machine, as the name suggests, is used to treat burrs on rough material surfaces. In the general mechanical industry, deburring machine equipment is mostly used. In the past, some metal materials relied on manual grinding, which had low efficiency and low cleanliness. The Linus deburring machine was developed to solve this pain point. The Linus deburring machine is divided into slag deburring, universal rolling brush deburring, and metal deburring Double sided deburring, etc.

This includes the number and type of grinding heads, wet or dry processing methods, selection of abrasives, and so on.

Mainly used for deburring precision grinding of workpieces, removing burrs from small gaps, etc., it is widely used for deburring precision stamping parts, gear parts, automotive parts, powder metallurgy parts, aviation, mechanical processing parts, etc., mainly for deburring hanging slag, chamfering, etc.

The deburring machine is designed for deburring, removing rust, iron nodules, polishing, removing scratches, and surface sanding of parts that have been laser cut from carbon steel and non-ferrous metals.