Edge Rounding Machine – 1000mm

The Edge Rounding Machine is designed to round sharp edges on metal plates after processing, improving safety and quality. It is particularly important for occupational safety in the post-processing phase, preventing sharp edges from causing injuries during handling.

This machine effectively deburrs and rounds edges on steel, aluminum, and stainless steel parts cut by laser, plasma, shear, or punching machines, ensuring a smooth, uniform finish.

Key Features & Benefits

✅ Edge Rounding – Smooths sharp edges to improve safety

✅ Deburring – Removes burrs formed after cutting processes

✅ Material Compatibility – Suitable for steel, aluminum, and stainless steel

✅ Heavy-Duty Processing – Handles up to 1000mm wide metal sheets

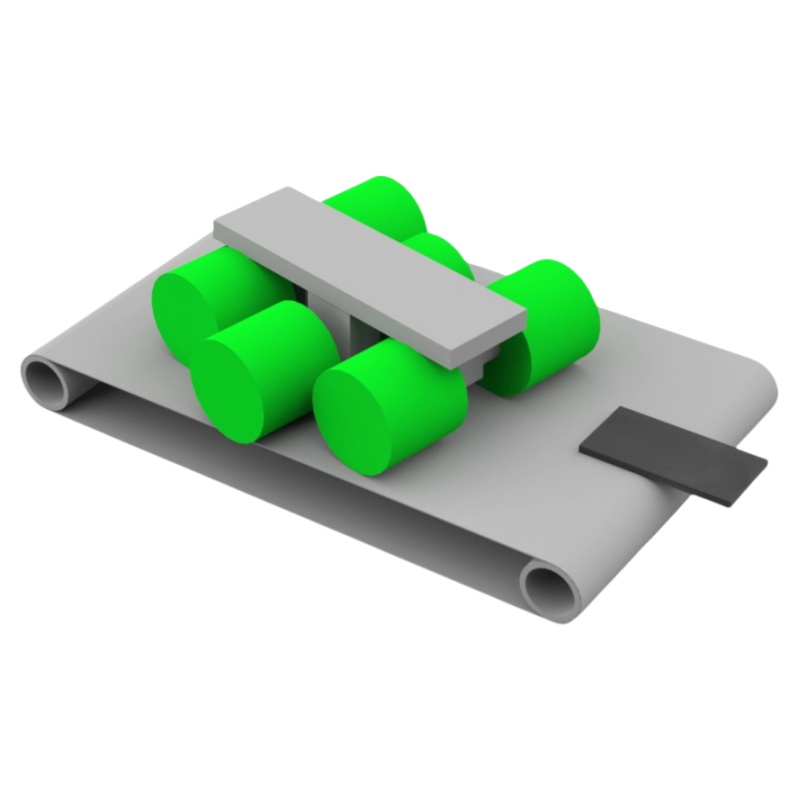

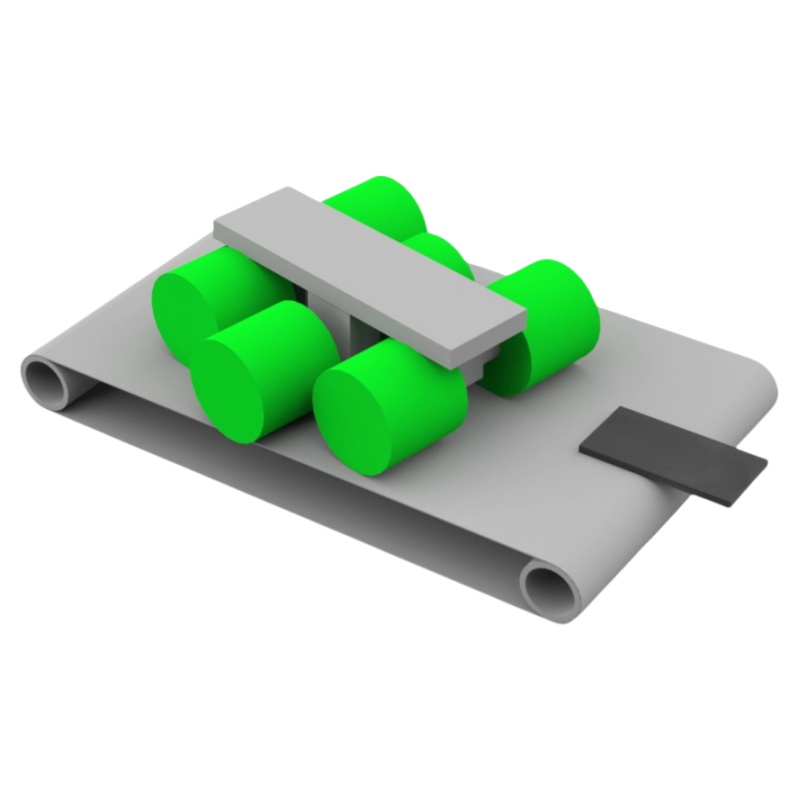

✅ Magnetic & Vacuum Holding System – Securely holds workpieces during processing

✅ High-Efficiency Flap Wheels – 6 flap wheels ensure consistent edge rounding

✅ Adjustable Conveyor Speed – 0.6–4.0 m/min for optimal performance

✅ Supports Small & Large Parts – Minimum part size 50x50mm

✅ Industrial Dust Extraction – Requires a minimum of 3000 m³/h airflow

Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Edge Rounding |

| Material Thickness | 0.5 - 80 mm |

| Max. Material Width | 1000 mm |

| Min. Part Dimensions | 50x50 mm |

| Max. Material Weight | 500 kg |

| Conveyor Speed | 0.6 - 4.0 m/min |

| Minimum Deduster Need | 3000 m³/h |

| Machine Power - Consumption | 12.7 - 20.2 kW |

| Machine Weight | 2800 kg |

| Holder System | Magnetic (Vacuum Optional) |

| Flap Wheels Quantity | 6 |

| Flap Wheels Dimensions | Ø300 x 300 mm |

| Conveyor Width | 1000 mm |

| Working Height | Adjustable |

| Processes | Deburring, Edge Rounding |

Applications

Laser-Cut & Plasma-Cut Parts – Removes sharp edges & burrs

Sheared or Punched Metal Plates – Uniformly rounds all edges

Sheet Metal Fabrication – Ensures safe handling & high-quality finishing

Automotive, Aerospace, & Industrial Manufacturing – Meets strict safety standards