1000W Laser Slat Cleaner – Laser Slat Cleaning Machine

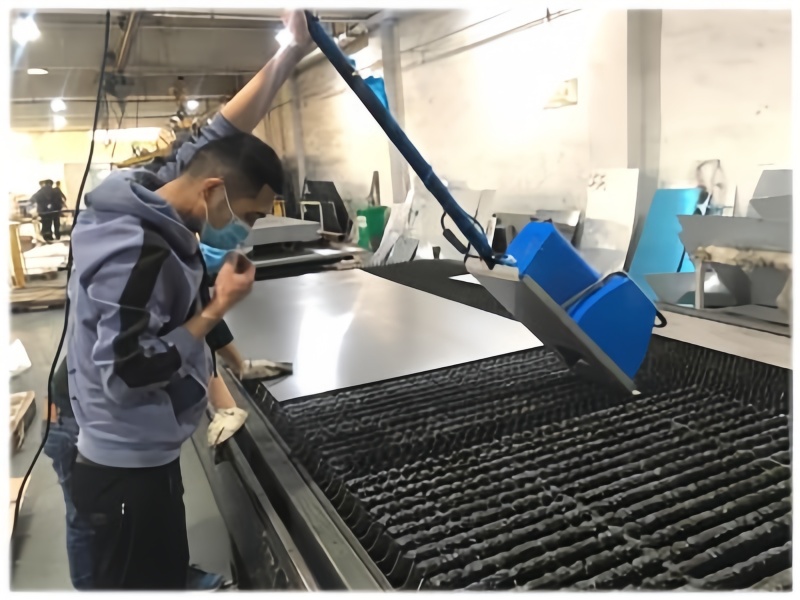

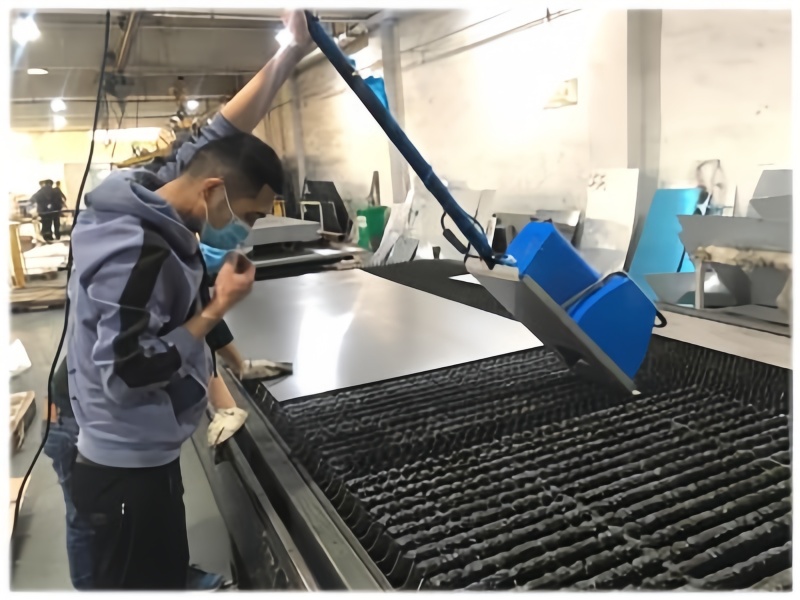

The 1000W Laser Slat Cleaner is an advanced cleaning machine specifically designed for the efficient cleaning and maintenance of laser cutting slats. With a 1000W power output, this machine effectively removes debris, dust, and residue that accumulate on slats during the laser cutting process. It ensures the optimal performance of the laser cutting system by keeping the cutting bed clean and free from contaminants, thereby enhancing cutting quality and prolonging the lifespan of the slats.

Key Features:

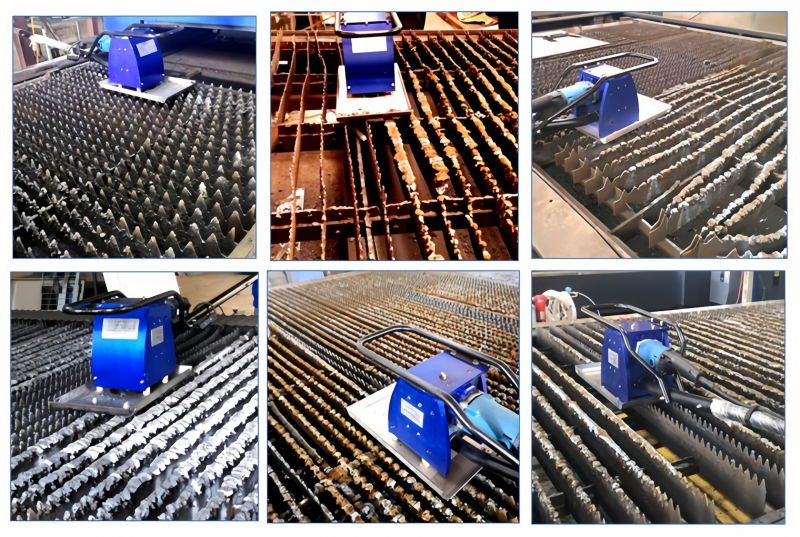

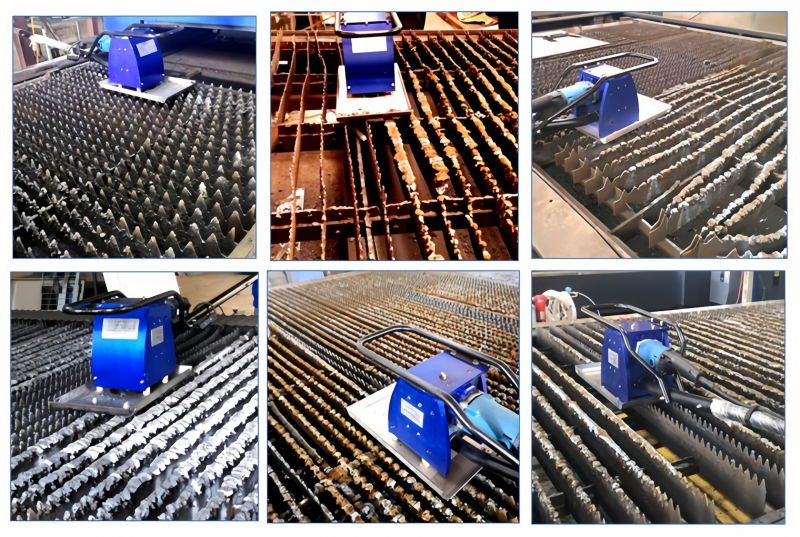

High Power Cleaning: The 1000W power output provides strong cleaning capability, capable of effectively removing metal dust, slag, and other debris from the laser cutting bed.

Automatic Operation: The machine features automated operation, reducing the need for manual intervention and ensuring consistent cleaning with minimal downtime.

Precision Slat Cleaning: The machine is equipped with a specially designed cleaning head that ensures thorough and precise cleaning of the slats, even in hard-to-reach areas.

Efficient Slat Maintenance: By maintaining clean slats, the laser cutting machine operates more efficiently, with improved cut quality, better heat dissipation, and reduced wear and tear on both the slats and the cutting machine.

Time and Cost Savings: Regular use of the laser slat cleaner reduces the need for manual cleaning, saving time and labor costs while improving overall system performance.

User-Friendly Interface: The machine is designed with an intuitive control system, making it easy to operate and maintain.

Durability: Built with robust components, the 1000W Laser Slat Cleaner is designed for long-lasting use in demanding industrial environments.

Applications:

Laser Cutting Industry: Ideal for keeping slats in top condition on laser cutting tables used for cutting metals such as steel, aluminum, and other materials.

Manufacturing: Helps improve the efficiency and quality of laser cutting in industries such as automotive, aerospace, and metal fabrication.

Maintenance: Extends the service life of slats by ensuring that debris and slag are effectively removed after each cutting cycle.

Benefits:

Improved Cutting Precision: Clean slats help maintain the accuracy of the laser cutting process.

Reduced Maintenance Costs: Minimizes wear on the laser cutting equipment by preventing the buildup of slag and debris.

Enhanced Operational Efficiency: Ensures smooth, continuous operation by preventing blockages and obstructions on the slats.

Specifications

| Model | STR-C1000 | STR-C1600 | STR-C2300 |

| Voltage | 220V/380V | 220V | 220V |

| Power | 1020W/1000W | 1600W | 2300W |

| Frequency | 50Hz | 50Hz | 50Hz |

| Laser Power Range | ≤6kW | - | - |

| Max Slag Width | ≤25mm | ≤25mm | ≤25mm |

| Slat Thickness | 3-5mm | 3-5mm | 3-8mm |

| Min Slat Spacing | 40mm | 40mm | 30mm |

| Continuous Work | 1 hour | 1 hour | 1 hour |

Applications:

Laser Cutting Machines: Efficiently cleans slag and residues from slats and cutting beds of laser cutters, ensuring optimal cutting performance.

Metal Fabrication: Ideal for the cleaning of slats used in CNC laser cutting, plasma cutting, and flame cutting.

Maintenance: A valuable tool for regular maintenance to prevent slag buildup, extend the life of cutting equipment, and improve cutting accuracy.

Slag Removal for Steel & Metal: Effective for removing steel slag, stainless steel slag, and other residues left after the cutting process.

Slat Cleaner for High-Power Lasers: Compatible with CNC laser cutting machines with power ratings up to 10kW.

Why Choose the Laser Slat Cleaner?

Cost-effective Maintenance: Regular use of this machine helps to maintain the quality of the laser cutting slats, reducing downtime and repair costs.

Increased Productivity: By keeping slats free from debris, the laser cutter can work more efficiently, improving overall productivity in the workshop.

Long-Term Durability: Built with high-quality materials to withstand rigorous industrial use, ensuring long-term service life.

User-Friendly: Easy to use with minimal training required, making it suitable for various operators in manufacturing environments.