Deburring and Edge Rounding Machine for Metal Parts

This deburring and edge rounding machine is designed to clean the burrs formed after the flame cutting processes of metal parts, round the sharp edges, and provide a smooth surface for the processed parts. It is suitable for use on materials such as steel, aluminum, and stainless steel, and can handle a variety of metal processing tasks, including heavy slag removal, deburring, edge rounding, and satin finishing.

This machine is designed for processing sheet metal, including stainless steel, carbon steel, aluminum plates, copper plates, and various non-ferrous metals. The equipment is used for:

Heavy Slag Removal: Removing slag formed during processes like cutting, including plasma, laser, and flame cutting.

Deburring: Removing sharp edges and burrs that form during metalworking operations such as punching, shearing, and cutting.

Edge Rounding: Creating smooth, rounded edges (with a controlled radius) to prevent sharp edges that may cause injury or stress concentration points in the metal.

Technical Specifications

| Specification | Details |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Heavy Slag Removal, Deburring, Edge Rounding, Satin Finishing |

| Processing Width | ≤ 1020 mm |

| Processing Thickness | 1 ~ 80 mm |

| Total Power | 50.35 kW |

| Hammer Disc Brush Diameter | Φ162 mm |

| Sanding Belt Dimensions | 1910 mm x 1050 mm |

| Brush Diameter | Φ300 mm x 300 mm |

| Conveyor Feeding Speed | 0.5 ~ 6 m/min (Variable Frequency) |

| Sanding Belt Speed | Approx. 14 m/s |

| Brush Rotation Speed (Self Rotation) | 8 ~ 26 m/s (Variable Frequency) |

| Brush Revolution Speed (Planetary Rotation) | 1 ~ 15 rpm (Variable Frequency) |

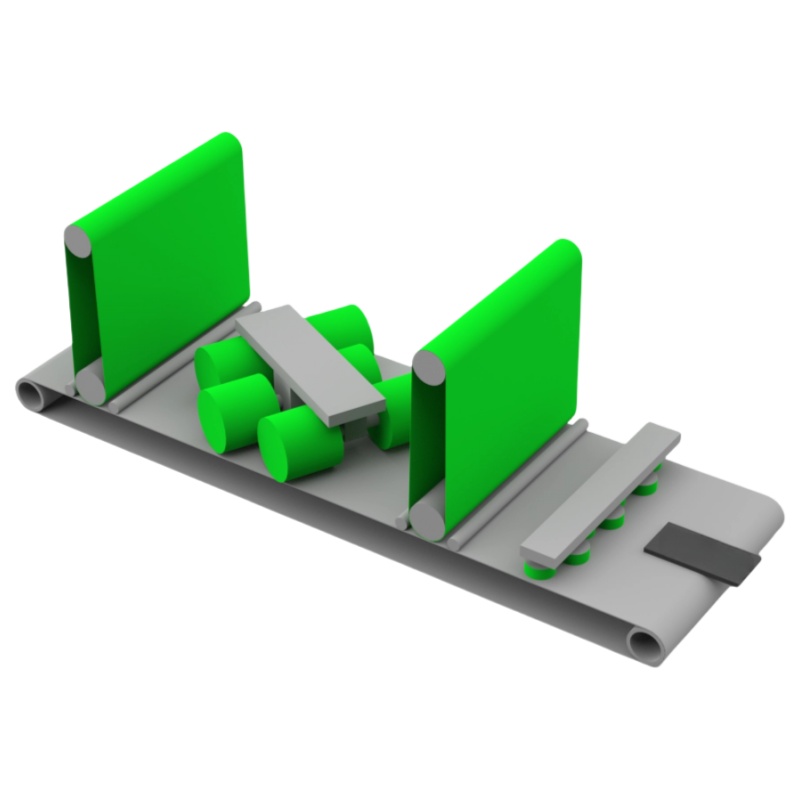

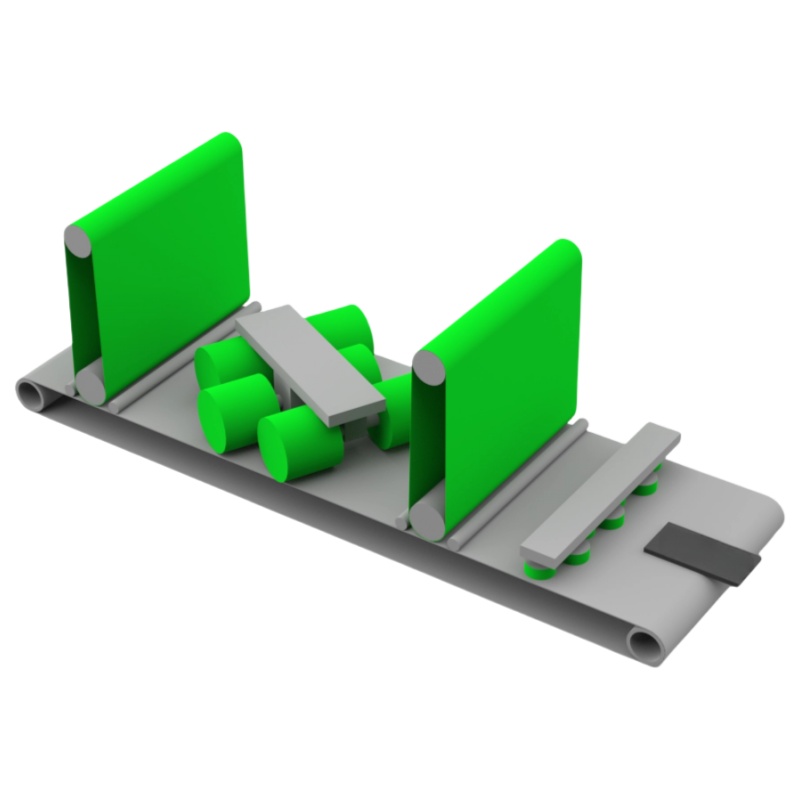

| Brush Planetary Axial Head Count | 1 |

| Brush Planetary Self-Rotation Head Count | 4 |

| Thickness Servo Adjustment Precision | 0.01 mm |

| Brush Compensation Servo Adjustment Precision | 0.01 mm |

| Grinding Consumables | Hammer Disc Brush, Sanding Belt, Brushes |

| Material Thickness | 0.5-80 mm |

| Min. Part Dimensions | 50 x 50 mm (flat parts, thickness 0.5 ~ 10 mm) |

| Max Material Weight | 500 kg |

| Conveyor Speed | 0.5 ~ 6.0 m/min (Variable Frequency) |

| Min. Deduster Need | 5000 m³/h |

| Machine Weight | Approx. 700 kg |

| Holder System | Magnetic (Vacuum Optional) |

Key Features and Advantages:

Heavy Slag Removal: The machine effectively removes slag and burrs from the metal parts that occur during flame cutting, plasma cutting, laser cutting, etc.

Edge Rounding: It rounds off sharp edges to create smoother, safer, and more polished edges on metal parts.

Satin Finishing: Achieve a uniform satin finish on metal surfaces for a more aesthetically pleasing and high-quality result.

Flexible Processing: The machine can process various materials, including steel, aluminum, and stainless steel, with thickness ranging from 1 to 80 mm and a width of up to 1020 mm.

High Precision: Features servo adjustments for thickness and brush compensation with an accuracy of 0.01 mm for precise and consistent results.

Efficient Grinding Consumables: Utilizes hammer disc brushes, sanding belts, and brushes to efficiently clean and finish the metal parts.

User-Friendly: The magnetic holder system (with optional vacuum) allows easy handling and processing of parts, and the variable frequency controls ensure flexible conveyor feeding speeds and rotation speeds.

Environmental Protection: Equipped with a dust collection system that operates at 5000 m³/h to remove dust and particles during the processing, creating a cleaner work environment.

Compact Design: Despite its powerful capabilities, the machine maintains a relatively compact size, weighing around 700 kg and providing ease of installation in most industrial settings.