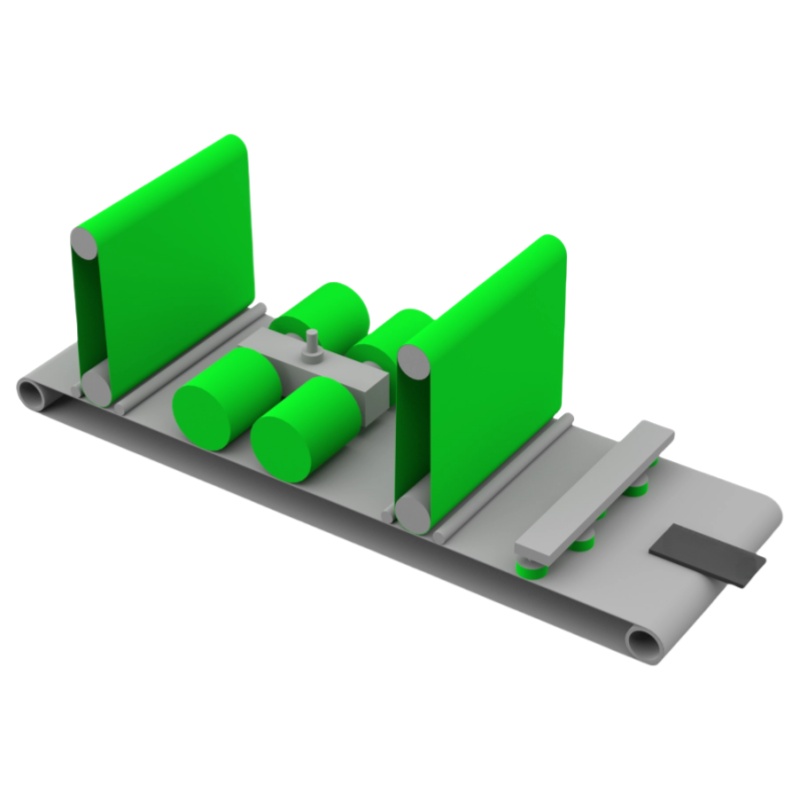

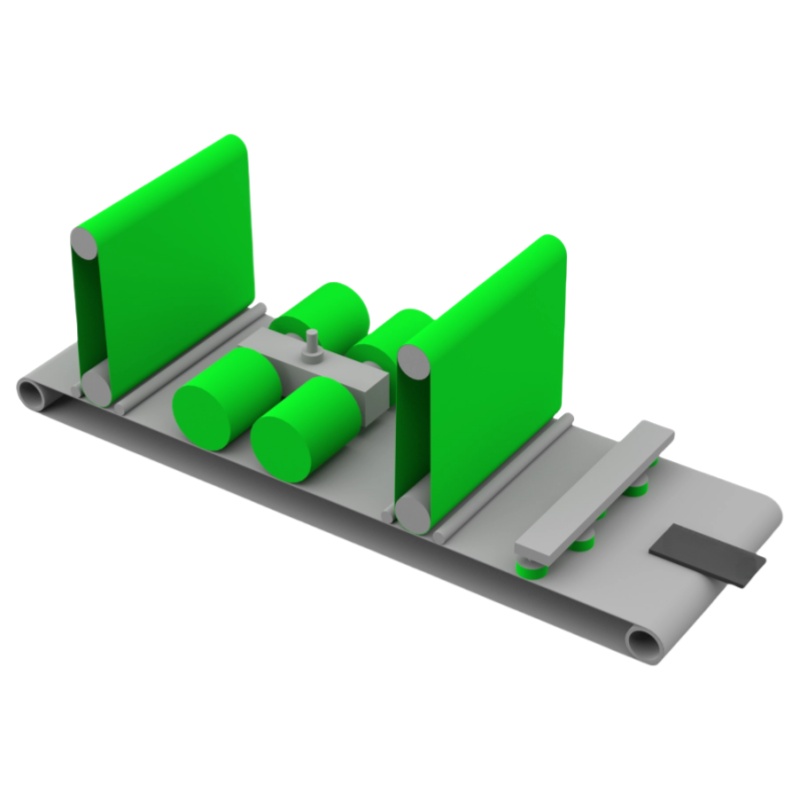

800mm Heavy Slag Removal, Deburring, and Edge Rounding Machine

This machine is designed to efficiently perform heavy slag removal, deburring, edge rounding, and satin finishing on various materials, including steel, aluminum, and stainless steel. It is specifically suited for handling burrs and slag generated from plasma, laser, and flame cutting processes. This system ensures high-quality surface treatment and smooth, uniform edges, optimizing both process efficiency and workpiece quality.

Key Features:

Materials Processed: Steel, Aluminum, Stainless Steel

Processes Supported:

Heavy Slag Removal

Deburring

Edge Rounding

Satin Finishing

Holder System: Magnetic (Vacuum Option Available)

Minimum Part Dimensions: 50mm x 50mm (for flat parts, thickness 0.5~10mm)

Maximum Material Weight: 500kg

This machine's design ensures flexibility, enabling it to handle parts of various shapes and sizes, including flat parts with thicknesses ranging from 1mm to 80mm. The system also allows for independent operation of individual units, making it adaptable to specific process requirements.

Technical Specifications:

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Heavy Slag Removal, Deburring, Edge Rounding, Satin Finishing |

| Holder System | Magnetic (Vacuum Optional) |

| Minimum Part Dimensions | 50 mm x 50 mm (flat parts, thickness 0.5~10mm) |

| Maximum Material Weight | 500 kg |

| Processing Width | ≤ 780 mm |

| Processing Thickness | 1 ~ 80 mm |

| Total Power | 50.35 kW |

| Hammer Disc Brush Diameter | Φ162 mm |

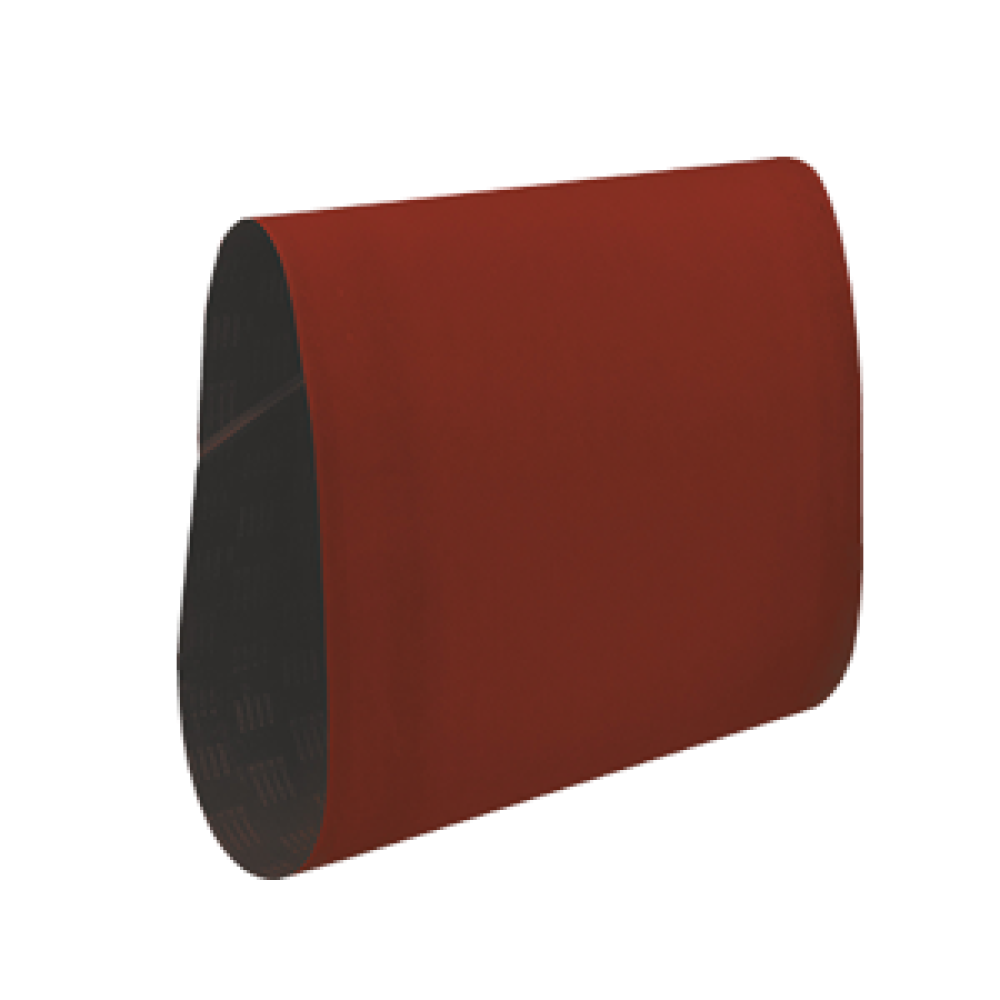

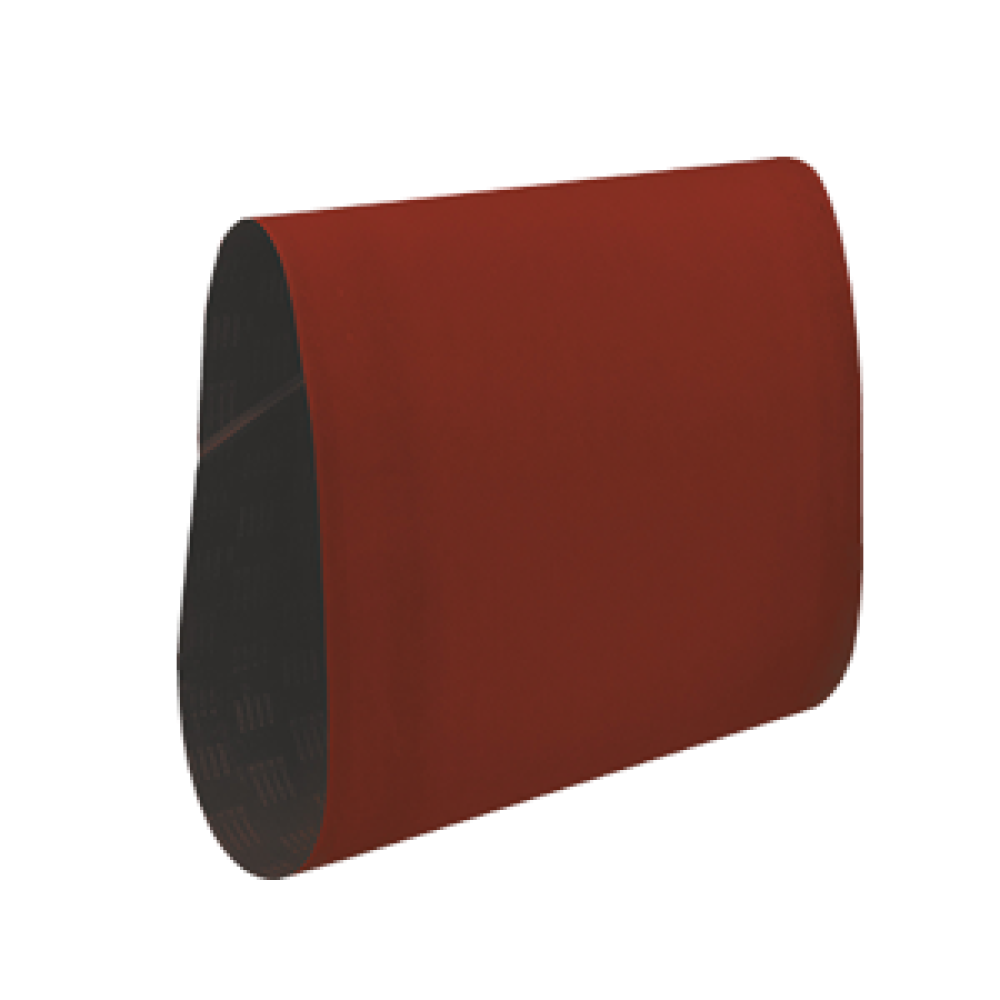

| Sanding Belt Dimensions | 1910 mm x 800 mm |

| Brush Diameter | Φ300 mm x 300 mm |

| Conveyor Feeding Speed | 0.5 ~ 6 m/min (Variable Frequency) |

| Sanding Belt Speed | Approx. 14 m/s |

| Brush Rotation Speed (Self Rotation) | 8 ~ 26 m/s (Variable Frequency) |

| Brush Revolution Speed (Planetary Rotation) | 1 ~ 15 rpm (Variable Frequency) |

| Brush Planetary Axial Head Count | 1 |

| Brush Planetary Self-Rotation Head Count | 4 |

| Thickness Servo Adjustment Precision | 0.01 mm |

| Brush Compensation Servo Adjustment Precision | 0.01 mm |

| Grinding Consumables | Hammer Disc Brush, Sanding Belt, Brushes |

| Dust Collection Airflow | 4000 m³/h |

| Machine Dimensions | L 4000 mm x W 2150 mm x H 2500 mm |

| Machine Weight | Approx. 5 tons |

Grinding Consumables Options:

The machine supports various types of grinding consumables, each designed for specific applications and material types. These include:

These consumables are optimized for different materials and processes, offering the flexibility to tailor the machine's operation to specific needs such as polishing, finishing, or deep deburring.

How the Machine Works:

Hammer Disc Brush Station: The machine begins the processing with a hammer disc brush, which strikes the workpiece's surface, removing large slag particles and burrs that are present after plasma, laser, or flame cutting.

Sanding Belt Station: Following the hammer disc brush, the sanding belt smooths the remaining burrs and performs light finishing and satin surface treatment, ensuring a high-quality finish on the workpiece.

Brush Station: The workpiece is then passed through the abrasive roller brushes, which use high-speed rotation and centrifugal force to finish the edges and holes. This step ensures that the edges are uniformly rounded and free from any burrs, providing a consistent R radius on all edges.

Independent Operation: Each section of the machine (hammer disc brush, sanding belt, and brush station) can operate independently, offering flexibility for different processing requirements.

Dust Collection System: The integrated wet dust extraction system keeps the work environment clean by capturing and filtering fine dust and metal particles. This helps ensure both worker safety and environmental compliance.

Applications:

This machine is particularly suited for industries where precise surface finishes and deburring are essential, such as in metalworking, automotive manufacturing, construction, and 5G communications. It efficiently handles parts of varying shapes and sizes, including sheets with complex edge geometries, offering high processing efficiency and consistent results.