Product Name:

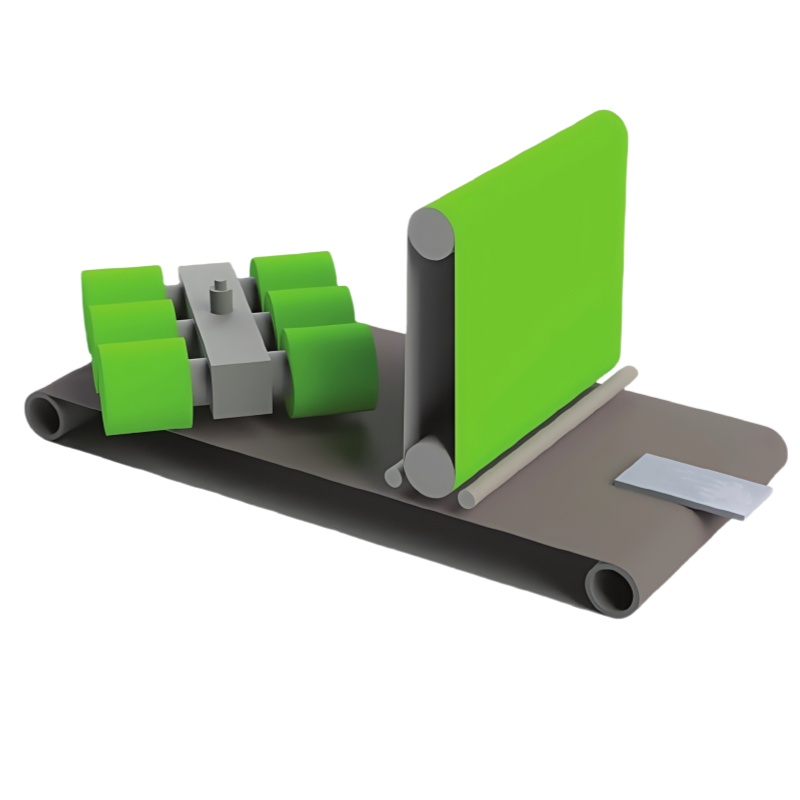

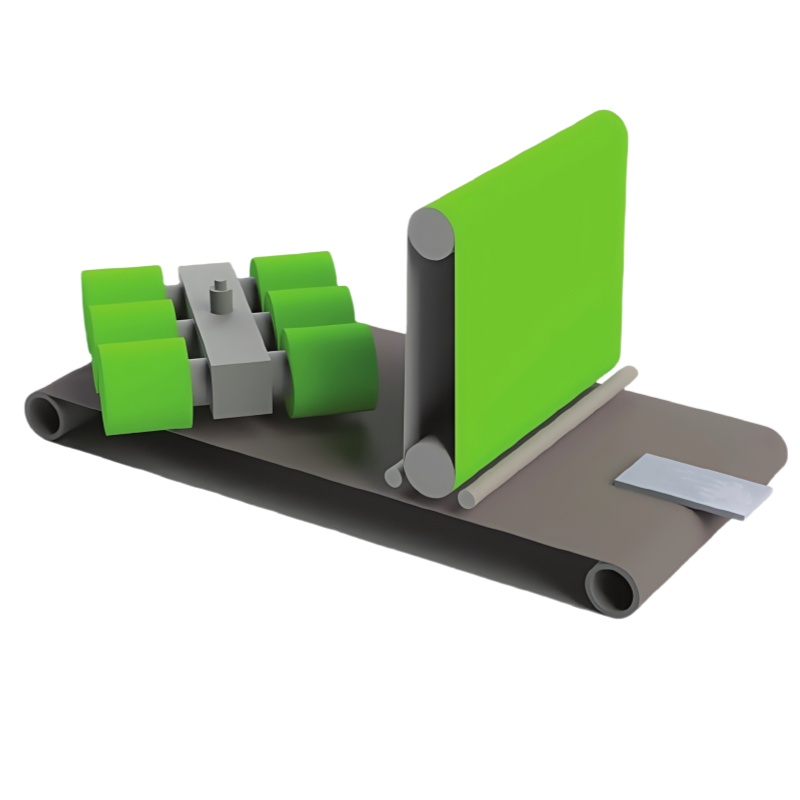

1000mm Deburring Machine for Edge Rounding and Metal Finishing

Product Overview:

This 1000mm wide deburring and metal finishing machine is designed for high-precision edge rounding, surface finishing, and deoxidation of various sheet metal materials including stainless steel, carbon steel, aluminum, copper, and non-ferrous metals. With a combination of a dry sanding belt station and six universal roller brush heads, the machine provides efficient, uniform, and safe deburring for parts with edges, holes, and contours — all in a single pass.

It is ideal for parts processed by laser cutting, punching, stamping, shearing, plasma cutting, or flame cutting, and ensures all edges achieve a smooth R-radius without damaging coatings or surface finishes.

⚙️ Key Processing Capabilities:

✅ Edge Rounding: Uniform R-radius edge rounding (up to R2mm), even on inner holes and complex contours

✅ Surface Finishing: Hairline finish, polishing, and deoxidation for stainless and coated sheets

✅ Multi-Directional Deburring: High-speed centrifugal grinding and scraping with six rotating brush heads

✅ One-Pass Efficiency: Simultaneous deburring and finishing for improved throughput

✅ Safe for Coated Parts: Soft abrasive brush wires ensure no damage to protective films or coatings

✅ Dust-Free Operation: Equipped with a wet dust collection system for safe and clean working conditions

✅ Vacuum Workholding: Built-in vacuum table secures parts ≥50×50mm without fixtures

Applications:

Deburring of sheet metal parts after punching, laser/plasma/flame cutting

360° edge rounding including inner holes

Pre-coating, pre-welding surface finishing

Surface oxidation removal

Hairline finish or decorative surface brushing

Working Principle:

Sanding Belt Station: Removes heavy burrs, slag particles, and oxidized layers.

Six Universal Roller Brushes: Opposite-direction rotation with planetary motion applies even force on edges and contours, ensuring full deburring and consistent rounding.

Independent Operation: Each processing unit can run independently:

Technical Specifications:

| Parameter | Specification |

| Max Processing Width | ≤1020 mm |

| Processing Thickness | 0.5 – 80 mm |

| Minimum Workpiece Size | 50 × 50 mm (solid parts) |

| Total Machine Power | 37.05 kW |

| Abrasive Belt Size | Φ1910 × 1050 mm |

| Brush Disc Size | Φ300 × 300 mm |

| Feed Speed | 0.5 – 6 m/min (VFD adjustable) |

| Belt Linear Speed | 18 m/s |

| Brush Rotation Speed | 8 – 26 m/s (VFD adjustable) |

| Brush Revolution Speed | 1 – 15 rpm (VFD adjustable) |

| Number of Rotary Brush Heads | 6 pcs |

| Planetary Head Assembly | 1 set |

| Servo Precision – Thickness Adj. | 0.01 mm |

| Servo Precision – Brush Comp. | 0.01 mm |

| Grinding Media | Abrasive belt + Rotary brush heads |

| Dust Collection Volume | 4000 m³/h |

| Machine Dimensions (L×W×H) | 3000 × 1950 × 2150 mm |

| Machine Weight | Approx. 3 Tons |

Key Configuration Highlights:

Sanding Motor: 11 kW (SHIYANG)

Brush Rotation Motors: 4 × 2.2 kW (SHIYANG)

Brush Revolution Motor: 750W (SHENGBANG)

Conveyor Motor: 2.2 kW (XINLING) with hypoid gear reducer

Vacuum Fan Motor: 15 kW with inverter control (Jiuzhou)

Servo Motors for Lifting & Compensation: 750W (VEICHI)

Control System: PLC + 7” Touchscreen (VEICHI)

Inverter Drives: VEICHI (all motion control)

Tracking & Tension Sensors: AIRTAC + Shanghai Hugong

Electrical Components: CHNT, NSK Bearings

Advantages at a Glance:

Increased Production Efficiency – Supports continuous feeding for large-scale batch orders

Superior Surface Quality – Rounding and brushing results far beyond manual finishing

Cost-Efficient – Lower per-part processing cost and reduced labor

Environmentally Safe – Efficient dust removal and grinding residue recycling

Smart Operation – Intuitive interface and modular operation for flexible use