Equipment Main Processing Range

1. Processed Products

Stainless steel, carbon steel, aluminum plate, copper plate, various non-ferrous metals, etc.

2. Equipment Functions

This equipment is a dry-type machine with a combination of one set of steel hammer disc brush station, one set of wide abrasive belt station, and one set of universal roller brush station. It is mainly used for edge deburring, hole deburring, metal sheet deslagging, wire drawing, deburring, polishing, and other processing. It can completely remove burrs generated in stamping, shearing, laser cutting, plasma cutting, flame cutting, and other processes in a single pass. The equipment ensures all edges and holes achieve a small R-angle effect, making the processing safe and reliable and ensuring high-quality workpieces.

Equipment Working Principle

This equipment first removes slag particles and burrs on the workpiece surface using a steel hammer disc brush station with lateral oscillation. Then, the abrasive belt station removes residual burrs and sands the surface. Finally, the universal roller brush station (comprising six sets of omnidirectional abrasive roller brushes with counter-rotating neighboring brushes and planetary motion) performs high-speed centrifugal polishing, scraping, shaving, and filing of edges and holes. This ensures thorough burr removal without affecting the workpiece's precision, achieving uniform R-angle edges (adjustable by selecting different processes and abrasives). The through-feed processing does not compromise dimensional accuracy.

Additionally, each station can operate independently:

The steel hammer brush station can remove edge slag.

The abrasive belt station can perform surface wire drawing, polishing, and deburring.

The roller brush station provides 360° burr removal, making it particularly effective for laser-cut or CNC-punched sheet metal with protective film. It removes burrs completely without damaging the film or scratching the sheet metal. The equipment's special flexible abrasive filaments are designed to target burrs only, making it an ideal solution for deburring without surface damage, especially for irregularly shaped workpieces.

The conveyor system includes a powerful vacuum negative pressure adsorption system, allowing through-feed processing for workpieces of at least 50mm × 50mm (for non-perforated workpieces with thickness 0.5~10mm). Special workpieces can be fixed using customized fixtures. The conveyor speed is adjustable via frequency conversion.

The equipment is equipped with a wet dust collector to minimize safety hazards and efficiently process grinding dust. A high-pressure, high-flow fan extracts the dust into the dust chamber, where water spray settles the dust particles into the water, ensuring environmentally friendly filtration and clean air discharge. This provides a better working environment for operators and allows for the recycling of metal grinding powders, contributing to sustainable production.

Advantages of Using This Equipment

Increased Production Efficiency – Continuous through-feed processing meets high-volume order demands.

Improved Product Quality – Ensures consistent workpiece processing quality, far superior to manual treatment.

Cost Savings – Lower processing costs per unit area compared to manual deburring.

Safety and Environmental Protection – Efficient dust collection improves worker safety and working conditions.

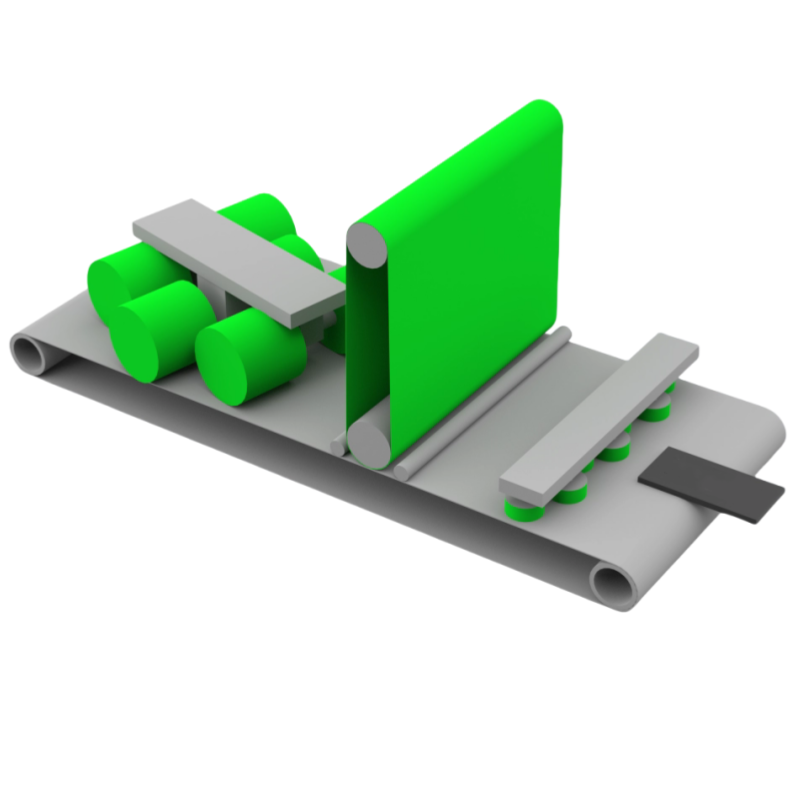

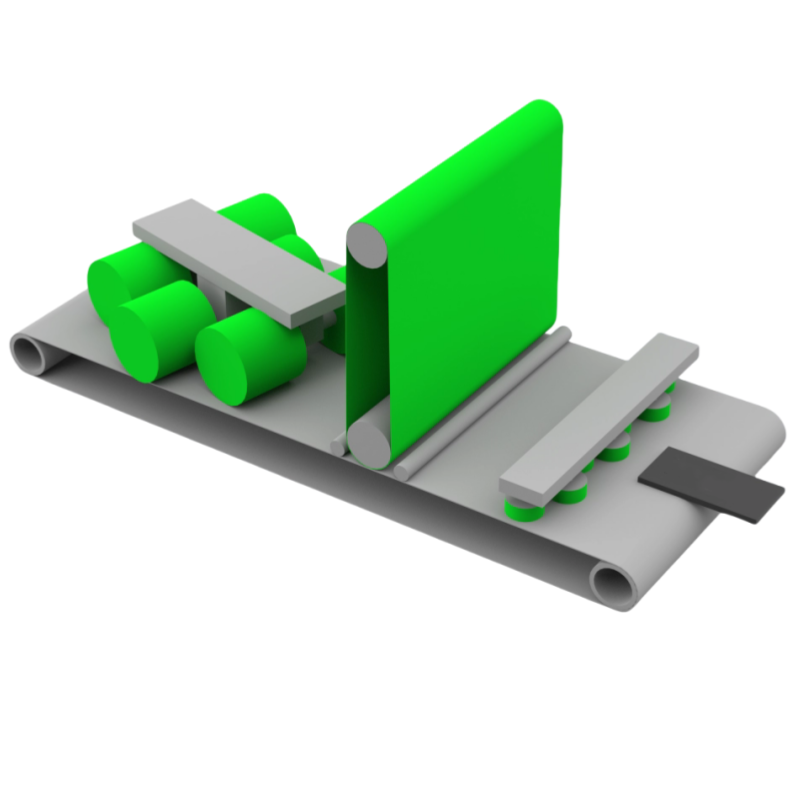

Equipment Structural Diagram

Main Technical Parameters

| Parameter | Specification |

| Processing Width | ≤1020mm |

| Processing Thickness | 1~80mm |

| Minimum Processing Size | 50mm×50mm (for non-perforated workpieces, thickness 0.5~10mm) |

| Total Power | 50.35KW |

| Steel Hammer Disc Brush Size | Φ162mm |

| Abrasive Belt Size | 1910×1050mm |

| Roller Brush Size | Φ300mm×300mm |

| Conveyor Speed | 0.5~6m/min (adjustable via frequency conversion) |

| Abrasive Belt Linear Speed | ~14m/s |

| Roller Brush Rotation Speed | 8~26m/s (adjustable via frequency conversion) |

| Roller Brush Planetary Rotation Speed | 1~15r/min (adjustable via frequency conversion) |

| Number of Planetary Rotation Shafts | 1 |

| Number of Planetary Self-Rotation Shafts | 6 |

| Processing Thickness Servo Adjustment Accuracy | 0.01mm |

| Roller Brush Compensation Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Steel Hammer Disc Brush + Abrasive Belt + Roller Brush |

| Dust Extraction Volume | 4000m³/h |

| Equipment Dimensions | L 3600mm × W 2150mm × H 2500mm |

| Total Weight | ~4.5T |

Main Equipment Configuration List

| Item | Specification/Model | Quantity | Function | Brand |

| Steel Hammer Disc Brush Main Motor | 7.5KW | 1 | Powers the steel hammer disc brush rotation | Shiyang |

| Steel Hammer Disc Brush Oscillation Motor | 1.5KW Reducer Motor | 1 | Drives the lateral oscillation of the steel hammer disc brush | Shengbang |

| Abrasive Belt Main Grinding Wheel | Φ185mm×1050mm | 1 | Used for abrasive belt grinding |

|

| Abrasive Belt Main Motor | 11KW | 1 | Powers the abrasive belt | Shiyang |

| Roller Brush Rotation Motor | 2.2KW | 3 | Drives roller brush self-rotation | Shiyang |

| Roller Brush Planetary Rotation Reducer Motor | 0.75KW | 1 | Powers roller brush planetary rotation | Shengbang |

| Roller Brush Lifting Servo Motor | 750W | 1 | Adjusts roller brush wear compensation | Weichuang |

| Conveyor Belt | Width 1050mm | 1 | Transports workpieces | Domestic |

| Conveyor Drive Motor | 3KW | 1 | Powers the conveyor | Leibo |

| Conveyor Reducer | BKA87 | 1 | Drives conveyor transmission | Leibo |

| Worktable Lifting Servo Motor | 750W | 1 | Adjusts processing thickness | Weichuang |

| Vacuum Adsorption Fan | 18.5KW | 1 | Provides vacuum suction | Jiuzhou |

| Vacuum Adsorption Fan Frequency Converter | 18.5KW | 1 | Controls vacuum suction speed | Weichuang |

| Steel Hammer Disc Brush Frequency Converter | 7.5KW | 1 | Adjusts steel hammer disc brush speed | Weichuang |

| Roller Brush Rotation Frequency Converter | 7.5KW | 1 | Adjusts roller brush rotation speed | Weichuang |

| Roller Brush Planetary Rotation Frequency Converter | 0.75KW | 1 | Adjusts roller brush planetary rotation speed | Weichuang |

| Conveyor Motor Frequency Converter | 4KW | 1 | Adjusts conveyor speed | Weichuang |

| High-Speed Bearings | Set | 1 | Supports high-speed rotation | NSK |

| Low-Voltage Electrical Components | Set | 1 | Electrical control components | Chint |

| Control System | PLC | 1 | Controls the entire machine | Weichuang |

| Touch Screen | 7-inch | 1 | Controls the entire machine | Weichuang |

Installation Requirements

Adequate level installation space (6m × 6m).

380V, 50Hz power supply (±10%).

Clean compressed air supply.

Included Documents