1000mm Edge Rounding Machine Overview

The 1000mm Edge Rounding Machine is a high-performance machine designed for rounding the sharp edges of metal materials, such as steel, aluminum, and stainless steel. This machine ensures the edges are safely and efficiently rounded to prevent injury during handling and to enhance the quality of subsequent processes such as painting and coating.

Key Features:

Wide Material Compatibility: Works with various metals including steel, aluminum, and stainless steel.

Flexible Processing: Suitable for material thicknesses ranging from 0.5mm to 80mm, and can handle materials up to 1000mm in width.

High Efficiency: The machine offers a conveyor speed range from 0.5 to 6.0 meters per minute, ensuring high productivity with consistent results.

Energy Efficient: With a power consumption of 12.17 kW, it delivers reliable performance without excessive energy usage.

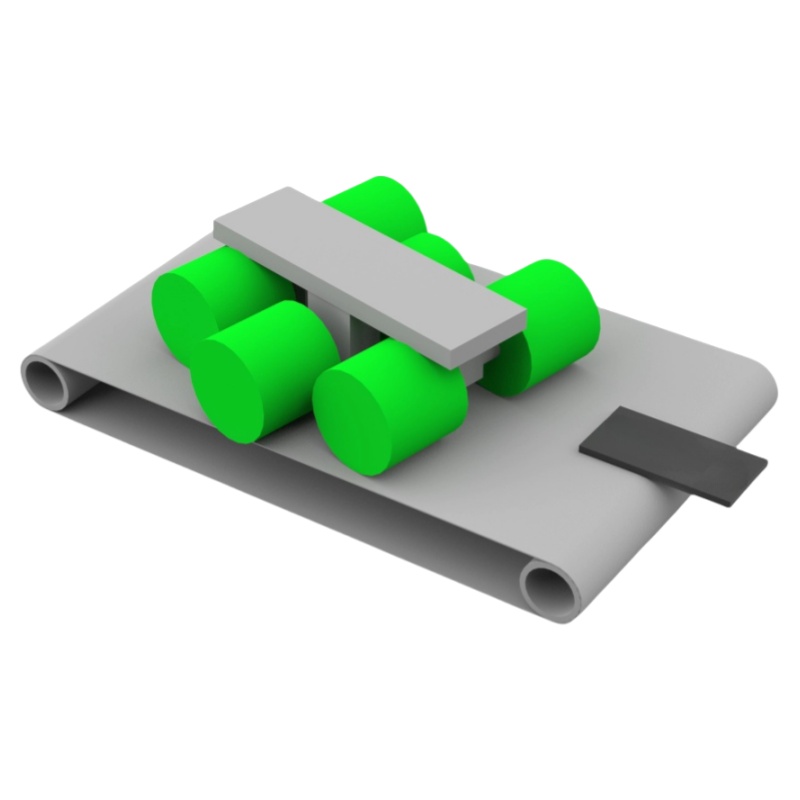

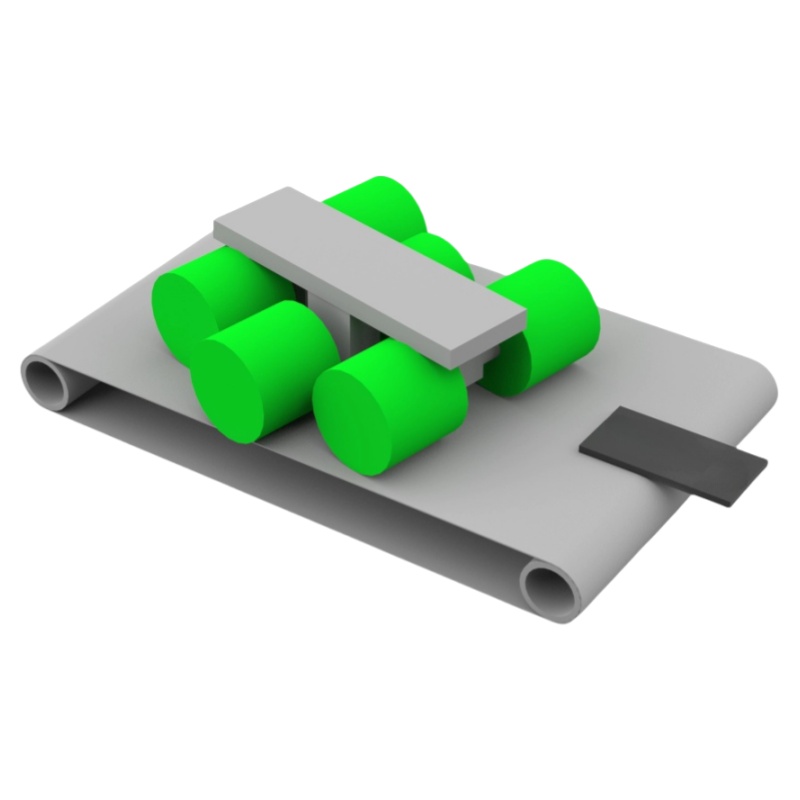

Magnetic Holder System: The machine uses a magnetic holder system to securely hold the material during the process, with an optional vacuum system for special requirements.

Precise Edge Rounding: The machine rounds the edges precisely to ensure safety, prevent injury, and improve paint adhesion.

Applications:

Metal Fabrication: Perfect for industries like automotive, aerospace, and construction, where sharp edges on metal parts need to be rounded after cutting or machining.

Paint and Coating Industries: The rounded edges improve the adhesion of paints and coatings, leading to a more durable and uniform finish.

Occupational Safety: The primary benefit of the edge rounding process is reducing the risks of injury during the handling and transportation of sharp-edged materials.

The Edge Rounding Machine is designed to round the sharp edges of metal materials such as steel, aluminum, and stainless steel. The primary purpose of this machine is to improve the safety of the materials by eliminating sharp edges, which can pose risks during handling and further processing. By rounding the edges, this machine ensures a safer working environment and enhances the quality of post-processing, particularly in applications involving paint adhesion.

Edge Rounding Machine

An Edge Rounding Machine is used to round the edges of metals. Sharp edges are rounded during processing, making the material safer to handle. This is crucial for occupational safety and improving paint adhesion in the post-processing phase.

Technical Specifications:

| Feature | Details |

| Material | Steel, Aluminum, and Stainless |

| Process | Edge Rounding |

| Material Thickness (mm) | 0.5 - 80 |

| Max. Material Width (mm) | 1000 |

| Min. Part Dimensions (mm) | 50 x 50 |

| Max. Material Weight (kg) | 500 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Min. Deduster Need (m³/h) | 3000 |

| Machine Power - Power Consumption (kW) | 12.7 / 20.2 |

| Machine Weight (kg) | 3000 |

| Holder System | Magnetic (Vacuum Optional) |

Model Specifications:

| Model | Flap Wheels Quantity | Flap Wheels Dimensions | Conveyor Width | Working Height | Conveyor Speed | Consumption | Processes |

| MSP-M1000 | 6 | Ø300 x 300 mm | 1000 mm | 80 mm | 0.5 - 6.0 m/min | 12.17 kW | Edge Rounding |

Applications:

Occupational Safety: The rounded edges reduce the risk of injury to workers during the handling of metal parts, making the workplace safer.

Paint Adhesion: The rounded edges improve the adhesion of coatings and paints, ensuring a more uniform and durable finish during the post-processing phase.

Metal Fabrication: Ideal for industries involved in metal fabrication, where parts require edge treatment after processes like laser cutting, stamping, or shearing.

Automotive and Aerospace: In these industries, sharp edges are not only dangerous but can also affect the structural integrity and paint adherence of components. The edge rounding machine ensures that all edges are smoothed, improving both safety and product quality.

Construction and Machinery: For metal parts used in construction or machinery, this machine ensures all edges are smooth and safe for further assembly and use.

Key Benefits:

Enhanced Safety: Reduces the likelihood of sharp edges that could cause injury or damage.

Improved Surface Treatment: Facilitates better coating, paint, and adhesive adhesion on the processed materials.

Versatile for Different Materials: Works efficiently with various metals such as steel, aluminum, and stainless steel.

Consistent Results: Ensures uniform rounding across all edges, maintaining high product quality.

Energy Efficient: Designed to optimize energy use, with a relatively low power consumption for its size.