Applications of the 1000mm Edge Rounding Machine

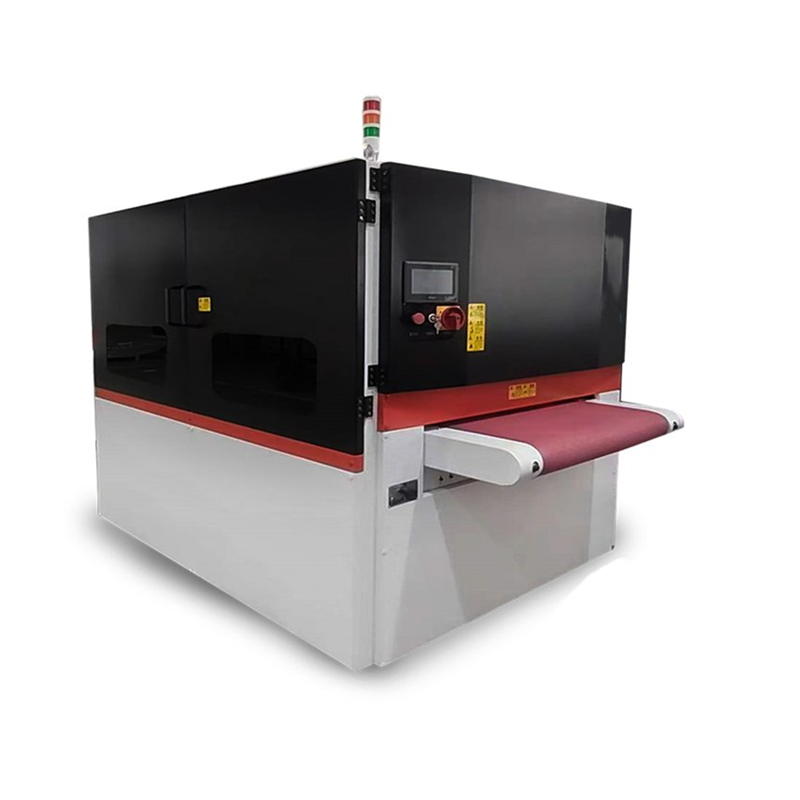

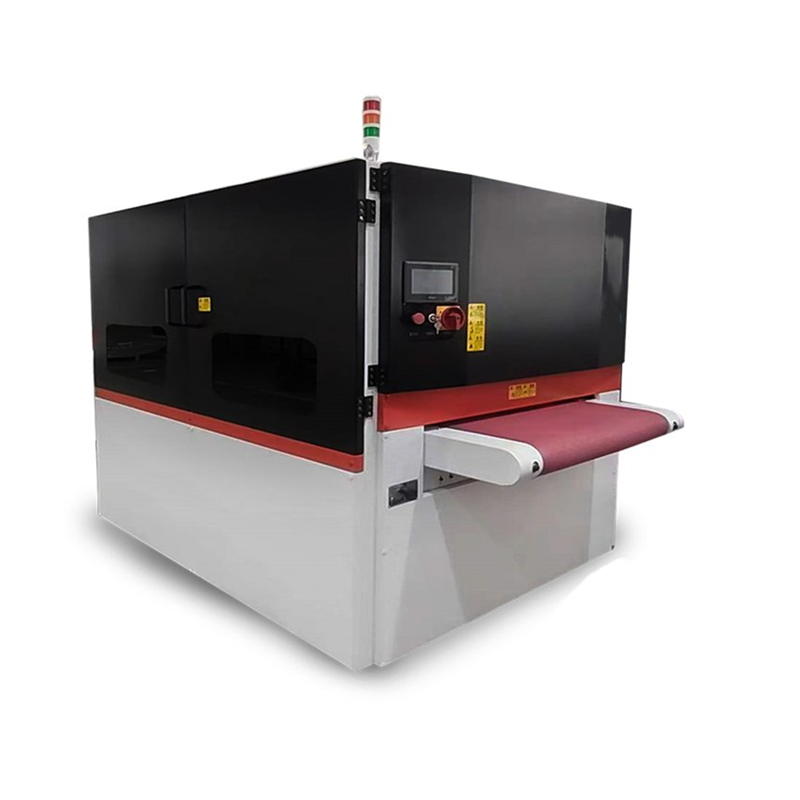

The 1000mm Edge Rounding Machine is a versatile and high-performance solution designed for deburring, edge rounding, and oxide removal of sheet metal components processed through various cutting and forming methods. It significantly improves part quality, enhances coating adhesion, and ensures worker safety.

Compatible Cutting & Processing Methods:

Technical Specifications

| Item | Details |

| Material Compatibility | Steel, Aluminum, Stainless Steel |

| Processing Type | Edge Rounding, Deburring, Oxide Removal |

| Material Thickness | 0 – 80 mm |

| Max. Material Width | 1000 mm |

| Min. Workpiece Size | 50 x 50 mm |

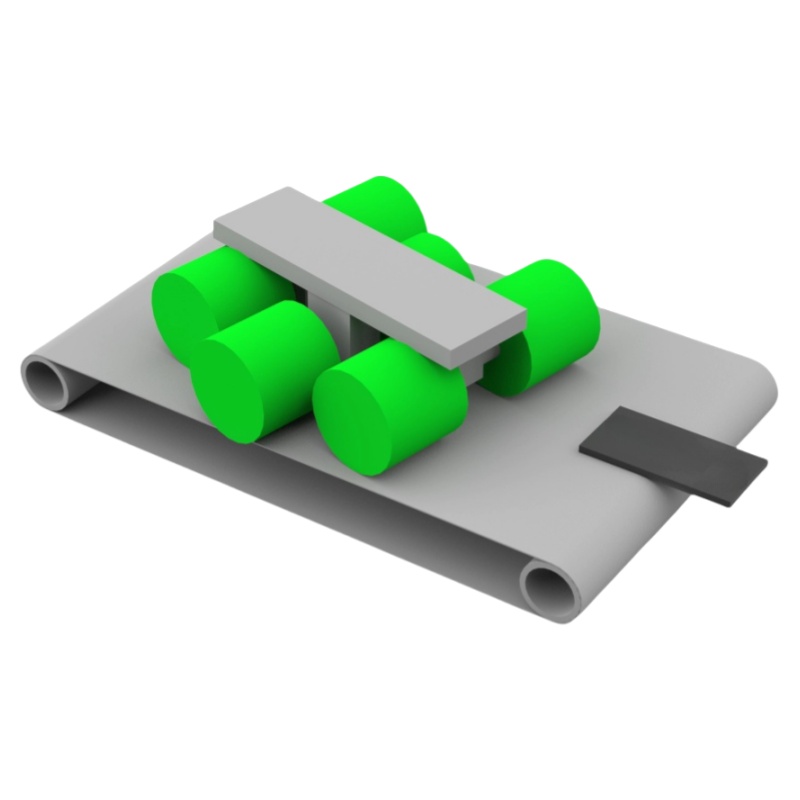

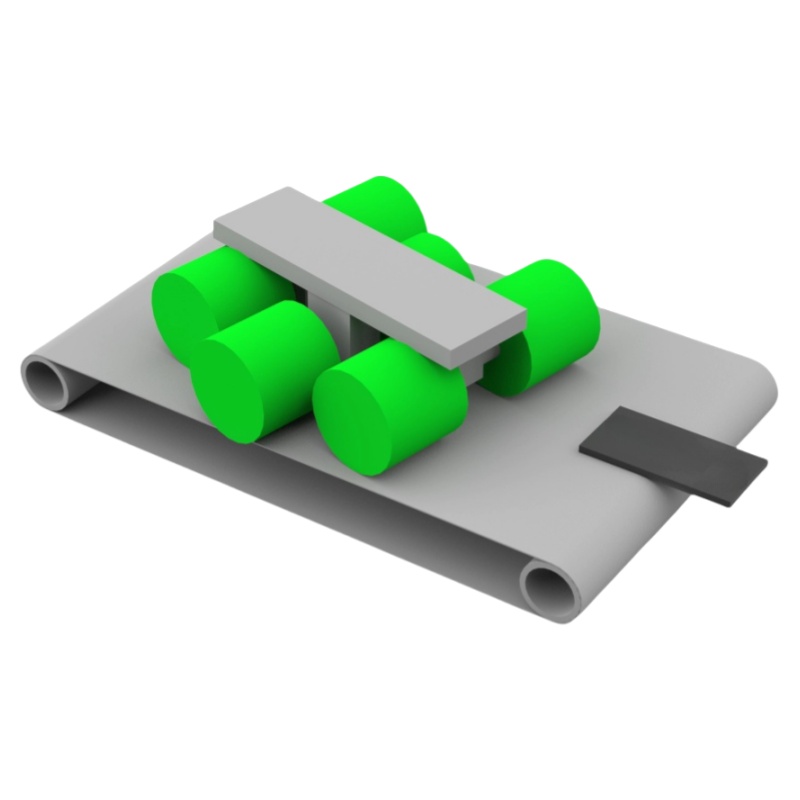

| Workpiece Holding System | Magnetic (Vacuum optional) |

| Flap Wheel Size | Ø300 x 300 mm |

⚙️ Supported Applications by Industry:

Sheet Metal Fabrication Workshops

HVAC and Electrical Enclosure Manufacturing

Automotive and Aerospace Components

Kitchen Equipment and Stainless Steel Fabrication

Machinery Parts and Structural Components

Signage, Decorative Panels, and Furniture Hardware

✅ Main Benefits:

Achieves uniform R-radius edge rounding (up to R1)

Compatible with steel, stainless steel, and aluminum

Processes parts from 0.5mm to 80mm thickness

Handles minimum part size 50x50mm

Magnetic or vacuum hold-down systems for part stability