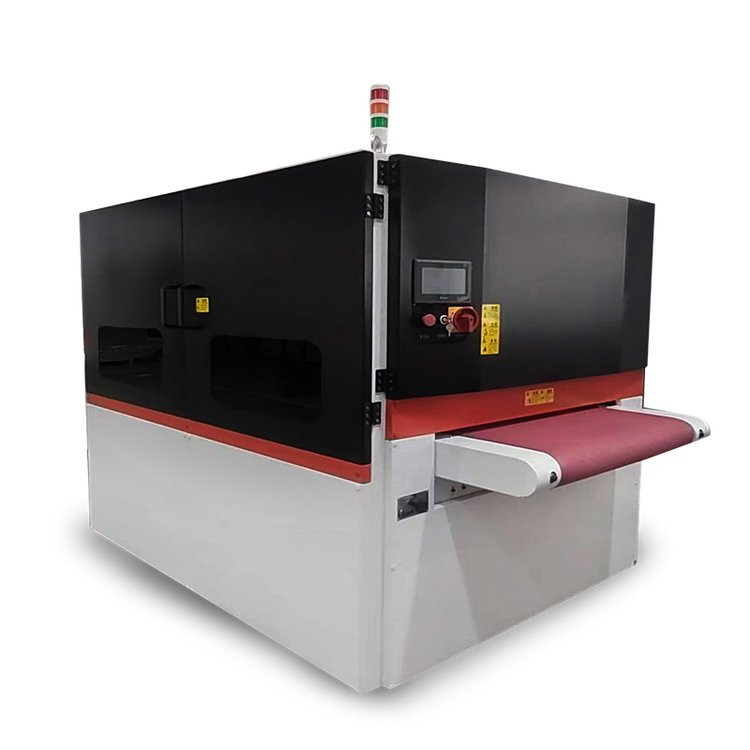

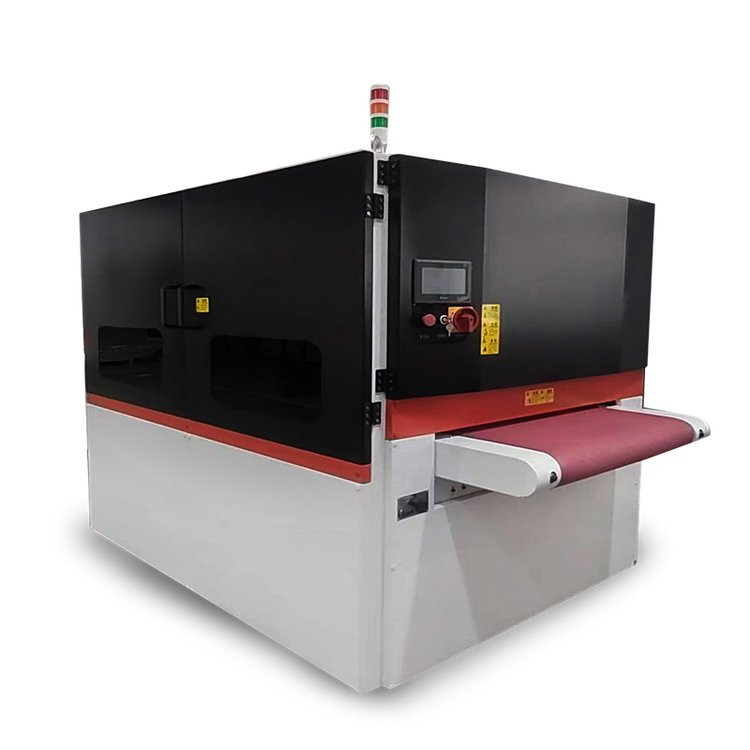

✅ 1000mm Metal Finishing & Deburring Machine

Precision Finishing | High Efficiency | Industrial-Grade Build

Product Overview

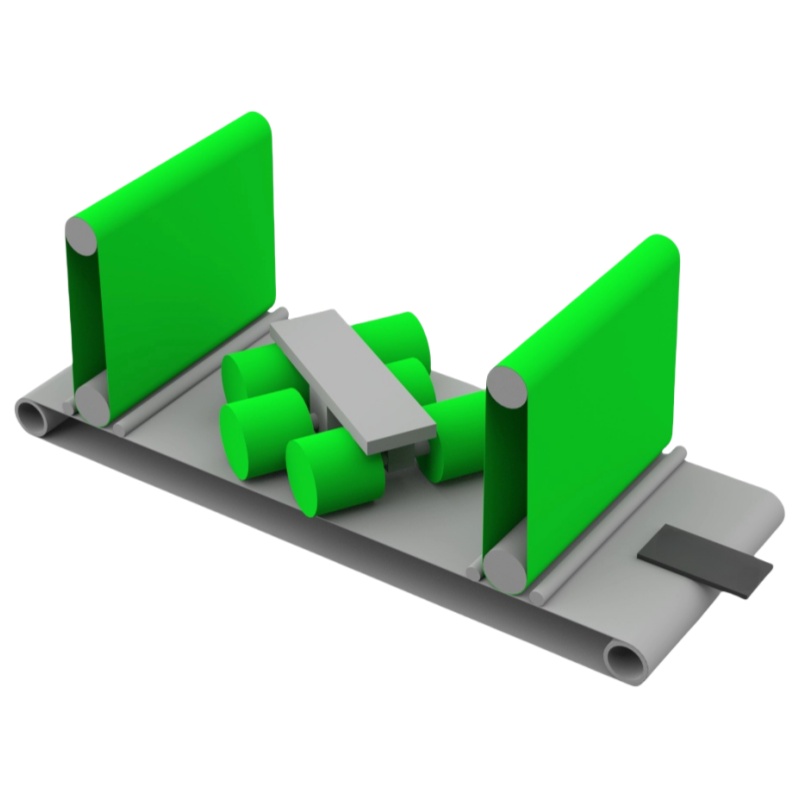

The 1000mm Metal Finishing & Deburring Machine is designed for the precise deburring, edge rounding, and surface finishing of sheet metal parts. With a wide working width of 1000mm, this machine is ideal for processing medium to large parts made from materials such as stainless steel, aluminum, carbon steel, and non-ferrous metals. It can handle parts from laser cutting, punching, plasma cutting, or shearing processes.

It is widely used in industries such as automotive manufacturing, metal fabrication, HVAC systems, kitchenware production, and signage fabrication.

⚙️ Key Features

Working Width: 1000mm, suitable for large parts and batches.

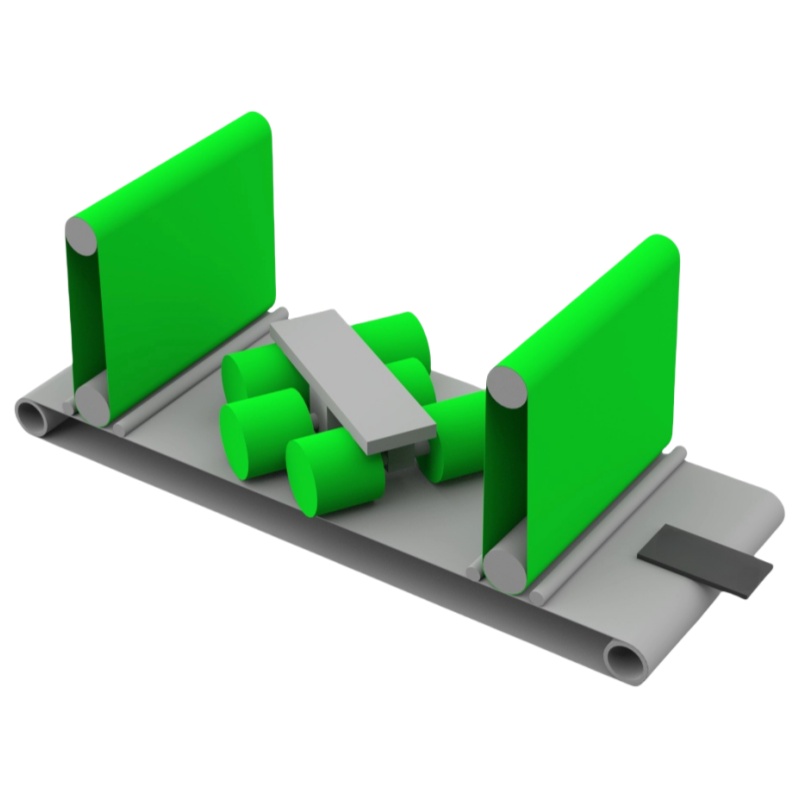

Multi-Stage Processing:

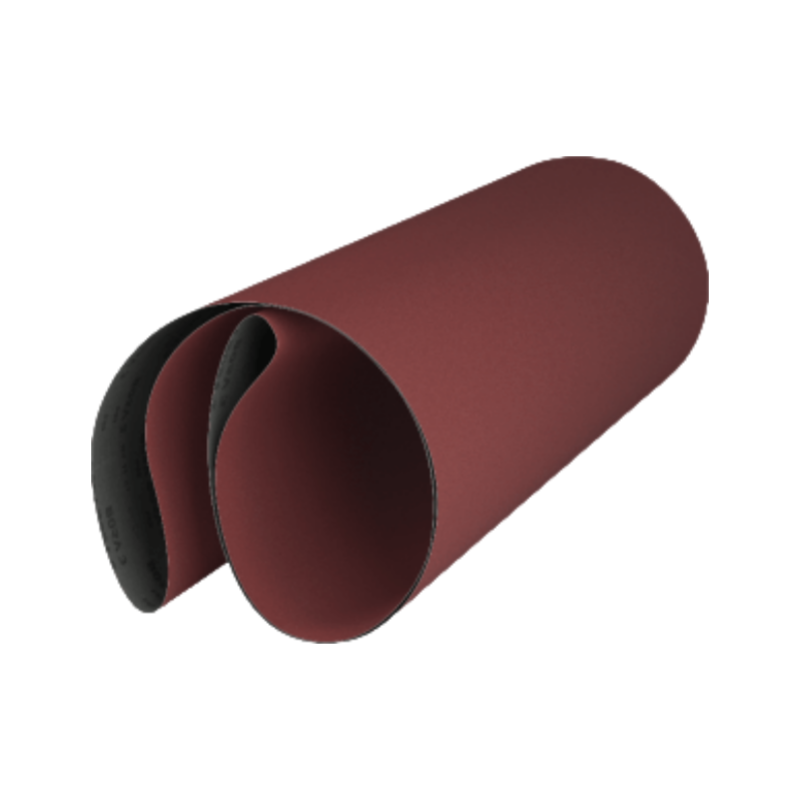

Abrasive Belt Station – For burr and slag removal

Flap Wheel / Brush Station – For edge rounding and smoothing

Finishing Brush Station – For final surface polishing and smoothing

Adjustable Speed:

Integrated Dust Extraction:

Easy-to-Use Interface:

Robust Industrial Design:

Technical Specifications

| Specification | Value |

| Max Working Width | 1000mm |

| Min Part Size | 50mm × 50mm |

| Processing Thickness | 0.5 – 80mm |

| Abrasive Belt Size | Ø1910mm × 1050mm |

| Flap Wheel Size | Ø300mm × 300mm |

| Feed Speed | 0.5 – 6 m/min (adjustable) |

| Brush Speed | 500 – 1400 rpm (adjustable) |

| Power Supply | ~40kW (depending on configuration) |

| Machine Dimensions | ~ 3500mm × 2200mm × 2200mm |

| Weight | ~ 3.5 – 4.0 tons |

| Dust Extraction Volume | ≥ 5000 m³/h |

Applications

Laser-Cut Sheet Metal Deburring

Edge Rounding and Finishing for safety and aesthetics

Oxide and Slag Removal after plasma or flame cutting

Smooth Surface Finish for better coating adhesion (e.g., powder coating, painting)

Deburring of Stamped, Sheared, or Punch-Cut Parts

Stainless Steel, Aluminum, and Copper Finishing