12000W Custom Precision Fiber Laser Cutting Machine for Red Copper Sheets (Model: ML-65150-12000)

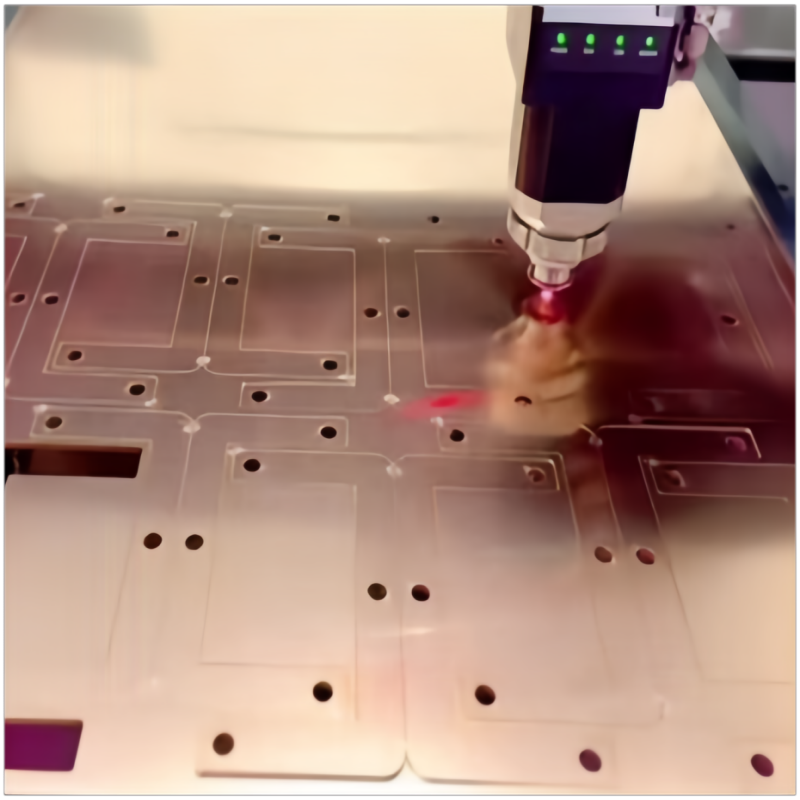

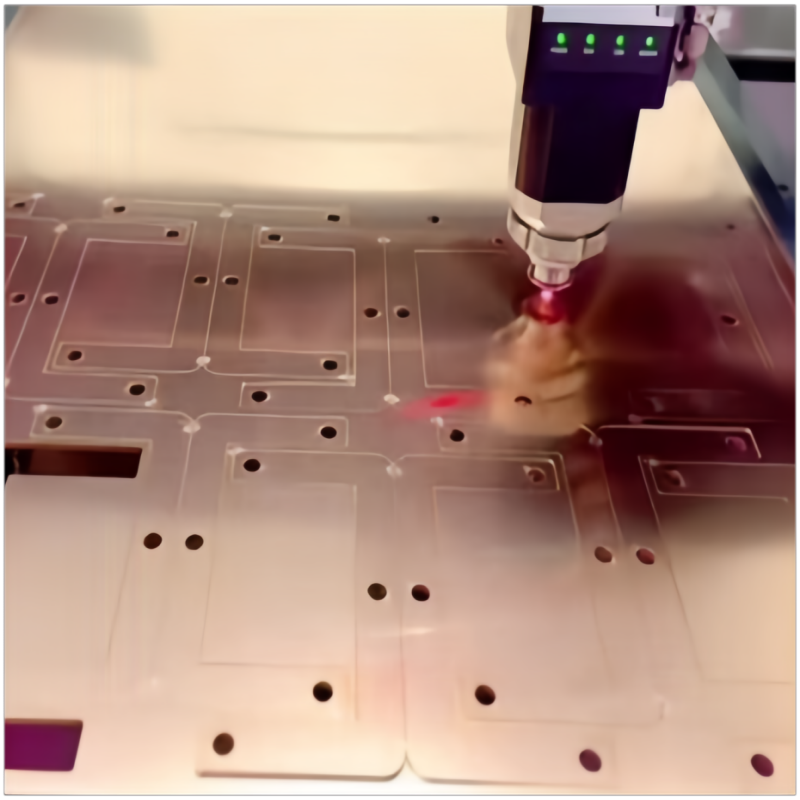

The ML-65150-12000 is a high-performance fiber laser cutting machine designed specifically for red copper (T2 copper) sheet cutting. With a powerful 12000W high-brightness fiber laser source and precision motion control system, it delivers excellent cutting performance, even on highly reflective and thermally conductive materials like copper. The system is engineered with a compact footprint, exceptional dust control, and non-contact cutting capabilities that ensure high surface quality and reduced post-processing.

Key Features

✅ Customized for Copper Sheet Cutting

Specially optimized for red copper sheet applications.

Maximum effective cutting area: 650 × 1500 mm.

Capable of cutting copper sheets from 0.1 mm up to 15 mm thickness.

Uses oxygen-assisted cutting for thicker copper plates.

✅ Pneumatic Fixture with Smart Platform

Rotary pneumatic clamping fixture ensures safe and stable material holding.

Integrated electric sliding platform with 1.3m stroke for easy material loading and unloading.

Optional vacuum lifting arm minimizes scratches on copper surfaces.

✅ High-Speed Linear Motor Platform

Equipped with maglev (magnetic levitation) linear motors on X, Y, Y1 axes.

Non-contact drive system ensures high acceleration (up to 1.5G), faster speed, and long-term stability compared to rack and screw drive systems.

✅ Marble Frame Machine Bed

Built on a one-piece granite base structure, ensuring vibration damping, excellent rigidity, and thermal stability.

Entire machine bed undergoes vibration aging treatment, effectively eliminating internal stresses.

✅ Advanced Cutting Control System

Uses the Bodor/BCS7000E (Baichu) control system with powerful software support (CypVision 3.0.0.14).

Features non-contact height-following system for precision focus adjustment.

Supports complex pattern cutting with high precision and responsiveness.

✅ High Brightness Anti-Reflection Laser Source

Custom 12000W Chuangxin fiber laser designed for high reflectivity materials like copper.

Output wavelength: 1070 nm, line width: ≤0.1mm.

✅ Dust-Free and Safe Design

Technical Specifications

| Item | Value |

| Model | ML-65150-12000 |

| Max Cutting Size | 650 mm × 1500 mm |

| Z-axis Stroke | 50 mm |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | 0.005 µm |

| Laser Power | 12000W (Chuangxin, customized) |

| Laser Wavelength | 1070 nm |

| Minimum Line Width | ≤0.1 mm |

| Cutting Speed (Max) | 18 m/min (e.g., 3mm copper) |

| Idle Speed | 50 m/min |

| Control System | Baichu BMC1214 + BCL3724 |

| Follow-Up System | Baichu BC100 |

| Software | CypVision-3.0.0.14 |

| Platform | Granite structure |

| Fixture Type | Pneumatic rotary clamping |

| Cooling System | HL-12000 Water chiller |

| Power Supply | 380V / 50Hz / 63A |

| Rated Power | ≤45 kW |

| Machine Dimensions | 2532 × 2100 × 1870 mm |

| Machine Weight | Approx. 4500 kg |

| Continuous Operation | 24 hours |

Core Components Configuration

| Component | Description / Brand |

| Laser Source | 12000W High-Brightness (Chuangxin) |

| Control System | Baichu 7000E |

| Cutting Head | Autofocus (Chuangxin) |

| Linear Motors | Guanye maglev motors |

| Guide Rails | THK P-Class |

| Cooling System | Hanli HL-12000 |

| Pneumatic Fixture | Custom rotary clamp |

| PC System | Dell Industrial PC (Windows 7) |

| Drive System | Guanye / Baichu dual drive |

| Electric Components | Schneider Electric |

Applications

Precision cutting of T2 red copper sheets

Electrical and electronic components

Battery connectors and terminals

Decorative metal parts

Precision hardware and copper processing

Advantages

✔️ Custom-engineered for high-reflective materials

✔️ Excellent surface finish with minimal post-polishing

✔️ Fully enclosed system for clean and safe operation

✔️ Non-contact motion and cutting for zero mechanical wear

✔️ Intelligent software with easy operation interface