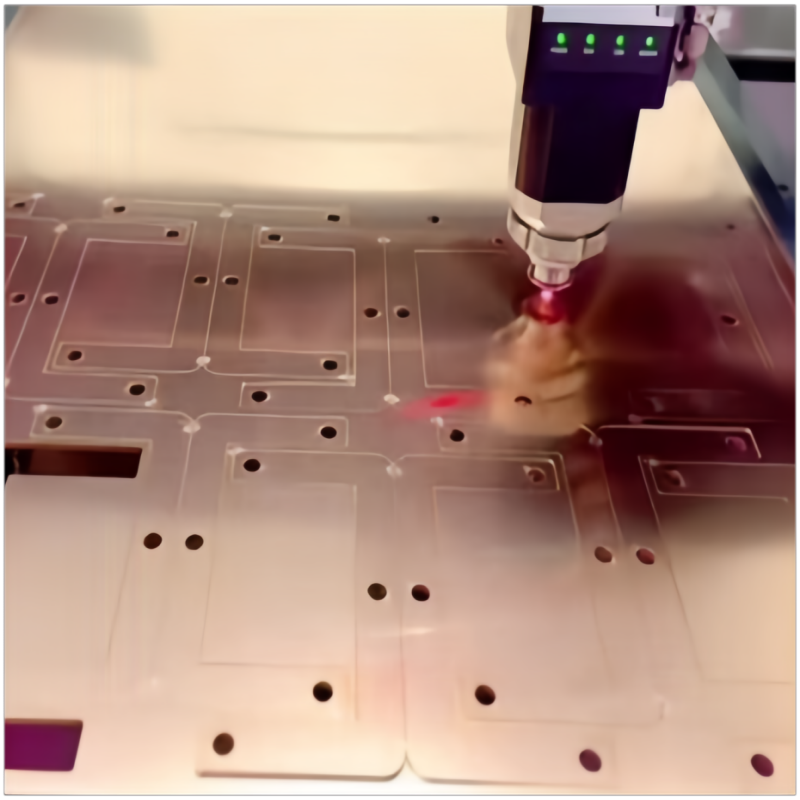

Cutting Control System: Custom high-precision cutting control system with an imported non-contact height tracking system that provides sensitive and accurate responses, unaffected by the workpiece shape, enabling high precision and fast speeds for any design.

Magnetic Suspension Motor Platform: Features non-contact movement, high acceleration, and greater speed compared to conventional gear, rack, or lead screw platforms, offering long-term stability during operation.

Marble Frame Design: The structure is made of a marble platform with an integrated design, providing high rigidity, high precision, and no deformation. It ensures the elimination of welding and processing stress through vibration aging treatment.

Custom Fiber Laser: High anti-reflection, high brightness fiber laser.

CAM Software: Professional CAM software is included, offering powerful functionality, stable operation, and easy learning.