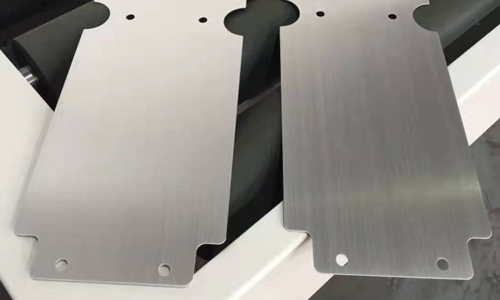

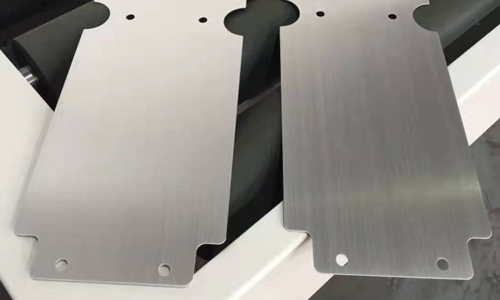

1350mm Automatic Sheet Metal Deburring Machine for Stainless Steel, Aluminum, and Polishing

Overview:

This 1350mm Automatic Sheet Metal Deburring Machine is designed for high-precision deburring, edge rounding, oxide removal, and polishing of metal sheets, including stainless steel and aluminum. It is ideal for use in industries that require high-quality metal finishing, including automotive, aerospace, sheet metal fabrication, and electronics. The machine is designed for automatic operation, offering high efficiency and consistency in metal processing.

——For Metal Deburring, Edge Rounding, Oxide Removal, Polishing, and Surface Brushing Processing

I. Processing Scope of the Equipment

Applicable Materials:

Stainless steel, carbon steel, aluminum, copper, and various other non-ferrous metals.

Functions of the Equipment:

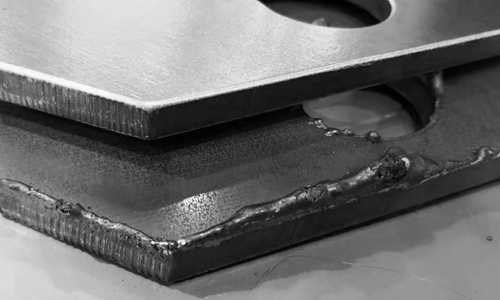

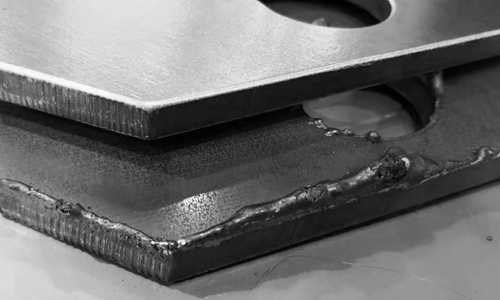

Deburring: Handles burrs from stamping, shearing, laser cutting, plasma cutting, flame cutting, and other processes.

Edge Rounding: Achieves small R-radius edges for safety and coating adhesion.

Surface Treatment: Performs brushing, polishing, and oxide removal for a smooth finish.

II. Working Principle of the Equipment

1. Two Main Working Stations:

2. Conveyor and Workpiece Fixing System:

3. Dust Collection and Environmental Design:

Equipped with a wet dust collection system to capture metal dust, ensuring environmental protection and a clean working environment.

High-efficiency dust absorption design keeps workers' environments safe and clean.

III. Advantages of the Equipment

High Efficiency:

High Quality:

Cost Savings:

Safety and Environmental Protection:

IV. Main Technical Parameters

| Parameter | Specification |

| Processing Width | ≤1330mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm×50mm (no hole workpiece) |

| Total Power | 47KW (excluding dust collection) |

| Abrasive Belt Size | Φ1910mm×1350mm |

| Abrasive Brush Size | Φ300mm×400mm |

| Conveyor Feeding Speed | 0.5~6m/min, frequency adjustable |

| Abrasive Belt Speed | About 18m/s |

| Brush Rotation Speed (Self) | 8~26m/s, frequency adjustable |

| Brush Rotation Speed (Planetary) | 1~15r/min, frequency adjustable |

| Processing Thickness Adjustment Precision | 0.01mm |

| Brush Compensation Adjustment Precision | 0.01mm |

| Dust Collection Volume | 5000m³/h |

| Equipment Dimensions | Length 3800mm × Width 2300mm × Height 2400mm |

| Total Weight | Approx. 6 tons |

1350mm automatic sheet metal deburring machine is designed to efficiently remove burrs, polish, and finish metal sheets up to 1350mm in width. These machines are suitable for materials such as stainless steel and aluminum, commonly used in industries like automotive, aerospace, and metal fabrication.

Key Features:

Processing Width: Capable of handling metal sheets up to 1350mm wide.

Material Compatibility: Effective on various metals, including stainless steel and aluminum.

Deburring and Polishing: Equipped to remove burrs and achieve desired surface finishes.

Automation: Automated operations enhance efficiency and consistency.

Adjustable Settings: Allows customization of processing parameters to meet specific requirements.

Applications:

Surface Finishing: Achieves smooth and polished surfaces on metal sheets.

Edge Rounding: Rounds sharp edges to improve safety and aesthetics.

Oxide Layer Removal: Eliminates oxide layers from laser-cut parts.

Preparation for Coating: Prepares surfaces for subsequent painting or coating processes.

Considerations When Selecting a Machine:

Material Type: Ensure compatibility with the specific metals you process.

Sheet Thickness: Verify the machine's capacity to handle your material thickness range.

Desired Finish: Determine if the machine can achieve the required surface quality.

Production Volume: Assess whether the machine's throughput aligns with your production needs.

Maintenance and Support: Consider the availability of technical support and ease of maintenance.

For instance, the 1350HSR model offers a maximum processing width of 1350mm and is suitable for various metal plates, including stainless steel and aluminum. It features multiple stations for deburring and polishing, with adjustable settings to accommodate different processing requirements.

When selecting a deburring machine, it's essential to evaluate your specific operational needs and consult with manufacturers or suppliers to ensure the chosen equipment meets your production and quality standards.