Large Working Width (1600mm / 62.99 inches):

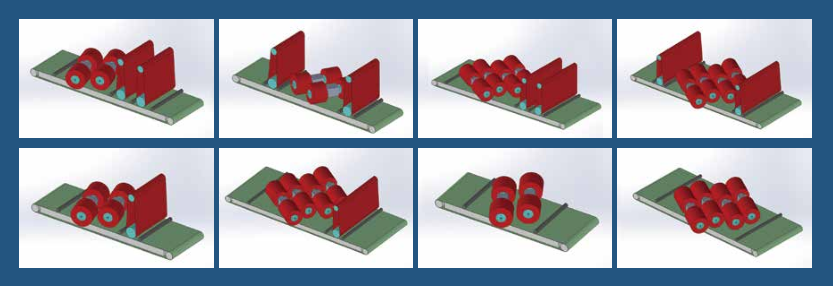

Deburring & Edge Radiusing:

Effectively removes burrs and sharp edges from laser-cut, plasma-cut, or punched sheet metal, while also providing smooth, rounded edges to improve part safety and functionality.

Versatile Finishing:

Capable of handling a variety of finishing tasks such as metal polishing, sanding, and laser oxide removal. This versatility allows for consistent, high-quality surface finishes across various metal types, including stainless steel, aluminum, copper, and carbon steel.

Heavy Slag Removal:

Efficient Dust Extraction:

Automatic & Manual Operation:

Technical Specifications:

-

| Specification | Value |

| Working Width | 1600mm (62.99 inches) |

| Processing Thickness | 1 ~ 150mm |

| Disc Brush Speed | 500-1400 rpm |

| Grinding Head Power | 0.75 kW per head |

| Vacuum Air Volume | 1000 m³/h |

| Total Power | 5.5 kW |

| Vacuum Platform Size | 300 x 300mm |

| Grinding Head Quantity | 2 |

| Disc Brush Size | φ162mm |

| Sandpaper Tray Size | φ150mm |

| Machine Dimensions | 2000 x 1500 x 2200 mm |

Applications:

Automotive Industry: Ideal for deburring and finishing automotive sheet metal parts, ensuring smooth edges and surfaces for better fitment and safety during assembly.

Aerospace Manufacturing: Used to clean and finish sheet metal parts for aircraft and aerospace components, removing burrs and slag for precise, high-quality finishes.

Metal Fabrication: Perfect for deburring and edge rounding of large metal sheets, which are used in machinery, tools, and other industrial applications.

General Manufacturing: Suitable for various industries requiring the cleaning and finishing of sheet metal parts, ensuring high-quality, burr-free surfaces.

Benefits:

High Efficiency: The 1600mm working width allows the machine to handle large volumes of sheet metal, making it ideal for industries with high throughput requirements.

Precision Finishing: Achieves clean, polished, and smooth surfaces on metal parts, which is crucial for aesthetic and functional purposes in the finished product.

Time-Saving: Reduces manual labor and speeds up the finishing process, leading to increased production rates.

Improved Safety and Quality: The deburring process enhances part safety by removing sharp edges and burrs, reducing the risk of injury during handling or assembly.

Environmental Benefits: The integrated dust extraction system keeps the workplace clean and reduces exposure to harmful particles, improving workplace safety.

Conclusion:

The 1600mm (62.99 inches) Sheet Metal Deburring Machine offers an efficient and versatile solution for large sheet metal parts that require deburring, finishing, and edge radiusing. Its robust construction, powerful vacuum system, and precision grinding heads make it ideal for industries such as automotive, aerospace, and general metal fabrication. With this machine, businesses can improve the quality of their products, enhance production efficiency, and ensure a cleaner, safer working environment.