1350mm Automatic Sheet Metal Deburring Machine for Edge Rounding of Metal Plates

Introduction:The Edge Rounding Machine is a specialized machine designed to round off the sharp edges of metal plates, which not only enhances safety during handling but also plays a key role in improving paint adhesion during post-processing. This machine is vital in industries where metal parts are frequently handled or used in products that require smooth edges for both safety and aesthetic reasons. It is suitable for a wide range of materials, including steel, aluminum, and stainless steel, and can process plates with thicknesses from 0.5mm to 80mm. The automatic operation of the machine ensures consistent and high-quality edge rounding with minimal operator intervention.

Key Features:

Suitable for steel, aluminum, and stainless steel.

Edge rounding process improves safety and paint adhesion.

Processes material thicknesses from 0.5mm to 80mm.

Maximum material width of 1350mm.

Variable conveyor speed allows for precise control (0.5-6.0 m/min).

Equipped with a magnetic holder system (optional vacuum system).

High processing capacity with a max material weight of up to 600kg.

Robust and durable design with relatively low energy consumption.

Technical Specifications

| Feature | Specification |

| Material | Steel, Aluminum, Stainless |

| Process | Edge Rounding |

| Material Thickness (mm) | 0.5 - 80 |

| Max Material Width (mm) | 1350 |

| Min Part Dimensions (mm) | 50 x 50 |

| Max Material Weight (kg) | 600 |

| Conveyor Speed (m/min) | 0.5 - 6.0 |

| Min Deduster Need (m³/h) | 5500 |

| Machine Power Consumption (kW) | 26.7 |

| Machine Weight (kg) | 2700 |

| Holder System | Magnetic (Vacuum Optional) |

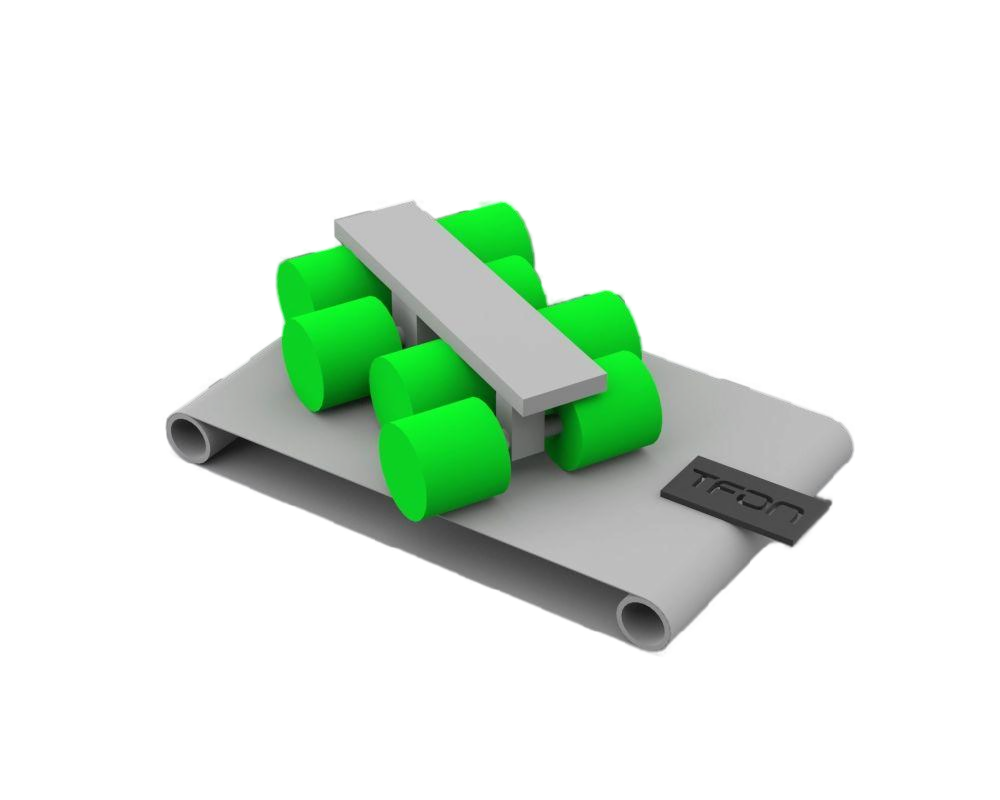

| Flap Wheels Quantity | 8 |

| Flap Wheel Dimensions | Ø300 x 400 mm |

| Conveyor Width | 1350 mm |

| Working Height | 80 mm |

| Model | MSP-M1350 |

| Processes | Edge Rounding |

Flap Wheel Dimensions:

Diameter: Ø300 mm

Length: 400 mm

This 1350mm Automatic Sheet Metal Deburring Machine is highly effective for industries that require high throughput and precision in edge rounding, deburring, and preparing metal sheets for further processing such as coating or welding.