Heavy Slag Removal, Deburring, and Edge Rounding Machine

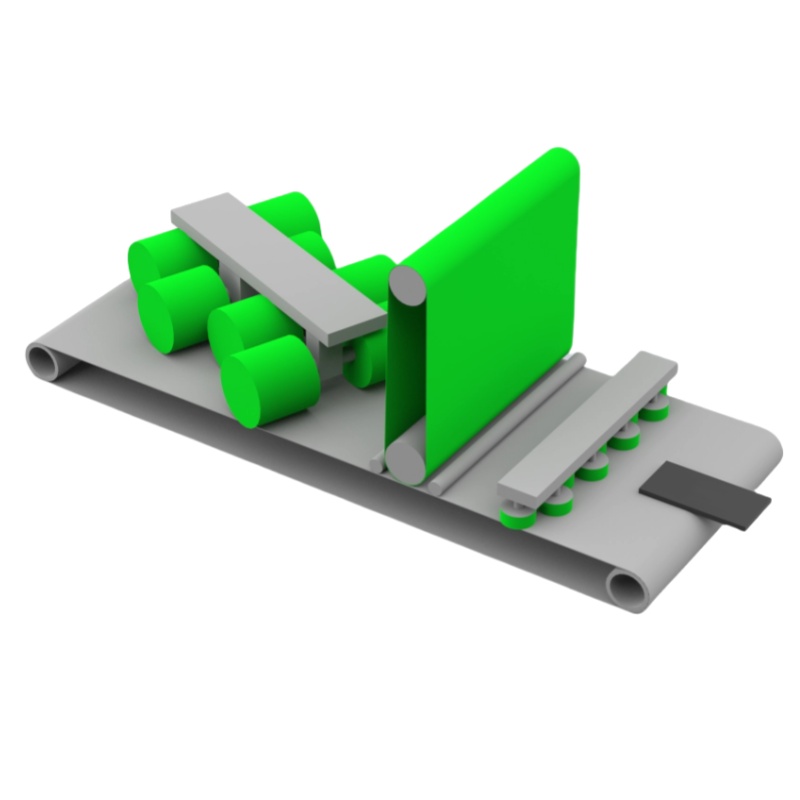

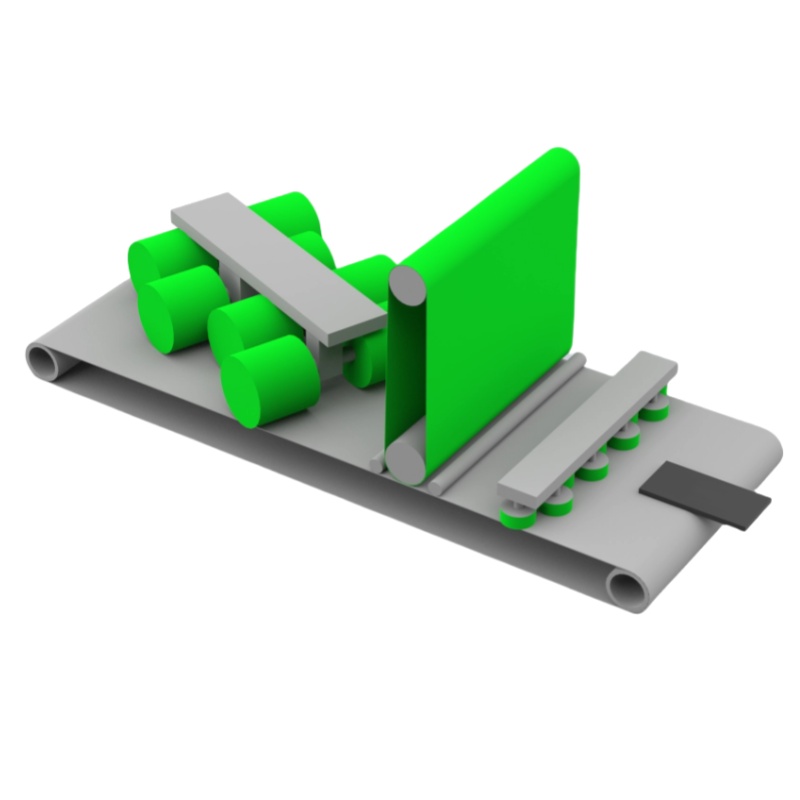

This equipment is designed for heavy slag removal, deburring, and edge rounding of metal sheets, particularly for products like carbon steel, stainless steel, aluminum plates, copper plates, and various other non-ferrous metals. It is a versatile, dry-type combination machine featuring hammer disc brushes, abrasive belt stations, and multi-axis abrasive roller brushes. It is specially designed to process edges and holes of workpieces, remove slag, achieve surface brushing, deburring, and polishing.

Main Features:

Product Applications: Works with carbon steel, stainless steel, aluminum, copper, and various non-ferrous metals.

Processes Supported:

Heavy slag removal

Deburring

Edge rounding

Surface brushing

Polishing

Oxide skin removal

The machine can handle burrs generated by punching, shearing, laser cutting, plasma cutting, and flame cutting, removing them efficiently and uniformly. This ensures that all edges and holes achieve a smooth, minimal R radius, which can be adjusted based on different materials and processing techniques. The operation is safe and reliable, producing a high-quality finish without compromising the dimensions of the workpiece.

Working Principle:

Hammer Disc Brush Station:

Abrasive Belt Station:

Multi-Axis Abrasive Roller Brushes:

A set of eight multi-axis abrasive roller brushes (with rotating and counter-rotating abrasive discs) performs high-speed centrifugal grinding, polishing, scraping, and deburring actions. These brushes remove burrs from the edges and holes, creating an even radius (R) angle on the workpiece. The precise R angle can be achieved through selection of different abrasive materials.

The machine can operate in different modes:

Independent Operation: The hammer disc brush, abrasive belt, and roller brushes can work independently to handle specific tasks, such as:

Hammer disc brush: Removes slag from edges.

Abrasive belt: Provides surface brushing, polishing, oxide skin removal, etc.

Abrasive roller brushes: Removes burrs and provides 360-degree edge deburring.

Special care is taken not to damage any protective films (e.g., post-laser cutting, or CNC punching with coated sheet metal). The design uses soft abrasives that only target burrs, ensuring the workpieces’ surfaces remain unharmed.

Conveyor System:

The machine uses a powerful magnetic conveyor system (vacuum option available) to hold the workpieces firmly in place. This allows for processing of 50mm x 50mm (without holes) and larger workpieces without the need for special tooling.

The system features variable speed to adjust the feeding process.

Dust Extraction:

The machine is equipped with a wet-type dust extraction system that significantly reduces safety hazards by efficiently collecting grinding dust. A high-pressure fan draws the dust into the extraction chamber, where it is trapped in water for environmental filtration. Clean air is then released back into the atmosphere, ensuring a clean working environment.

Technical Specifications:

| Feature | Specification |

| Material | Steel, Aluminum, Stainless Steel |

| Process | Heavy Slag Removal, Deburring, Edge Rounding |

| Holder System | Magnetic (Vacuum Optional) |

| Processing Width | ≤ 1330mm |

| Processing Thickness | 0.5~80mm |

| Minimum Processing Size | 50mm x 50mm (No-hole workpieces) |

| Total Machine Power | 45.5 kW (Excluding dust collection system) |

| Hammer Disc Brush Diameter | Ø 162mm |

| Abrasive Belt Size | Φ1910mm x 1350mm |

| Abrasive Roller Brush Size | Φ300mm x 400mm |

| Conveyor Feed Speed | 0.5~6m/min (Variable Speed) |

| Abrasive Belt Line Speed | ~18m/s |

| Roller Brush Rotation Speed | 8~26m/s (Variable Speed) |

| Roller Brush Revolving Speed | 1~15r/min (Variable Speed) |

| Planetary Revolving Axes | 1 |

| Planetary Rotating Axes | 8 |

| Thickness Servo Adjustment Accuracy | 0.01mm |

| Brush Compensation Servo Adjustment Accuracy | 0.01mm |

| Grinding Consumables | Hammer Disc Brush, Abrasive Belt, Roller Brushes |

| Dust Extraction Air Volume | 5000m³/h |

| Machine Dimensions | L 4500mm x W 2300mm x H 2500mm |

| Machine Weight | ~6T |

Conclusion:

Conclusion:

This machine is an efficient and reliable solution for slag removal, deburring, and edge rounding in the metalworking industry. Its versatile functionality, coupled with a powerful conveyor and precise control mechanisms, allows it to process a wide range of materials, including carbon steel, stainless steel, aluminum, copper, and other non-ferrous metals, while maintaining the precision and integrity of the workpieces.