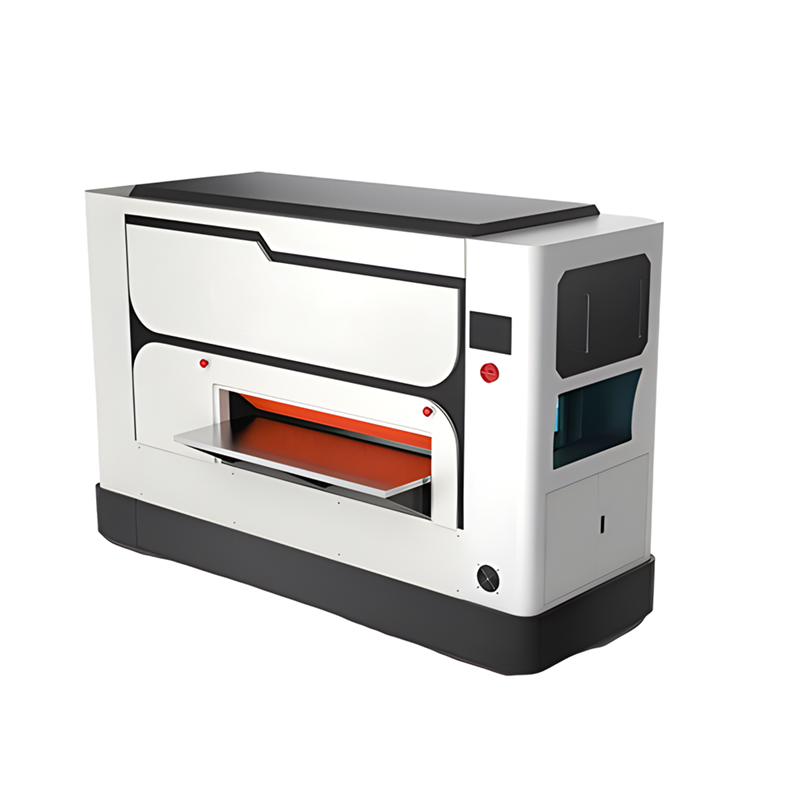

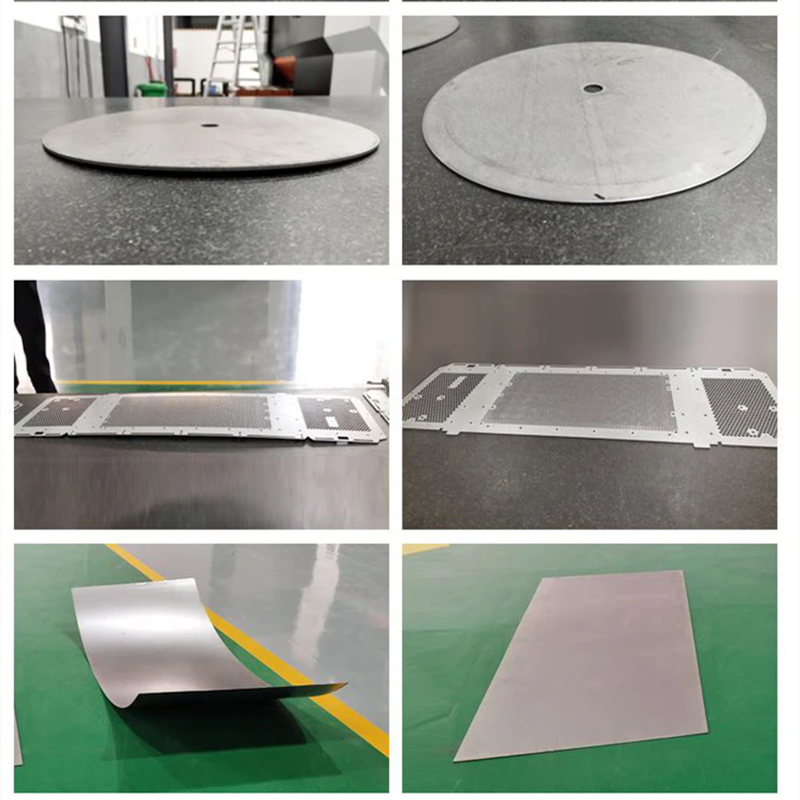

200-2200mm Precision Levelers | Plate & Sheet Metal Roller Levelers (0.5-2.5mm Thickness)

Introduction to Precision Levelers for Metal Sheets

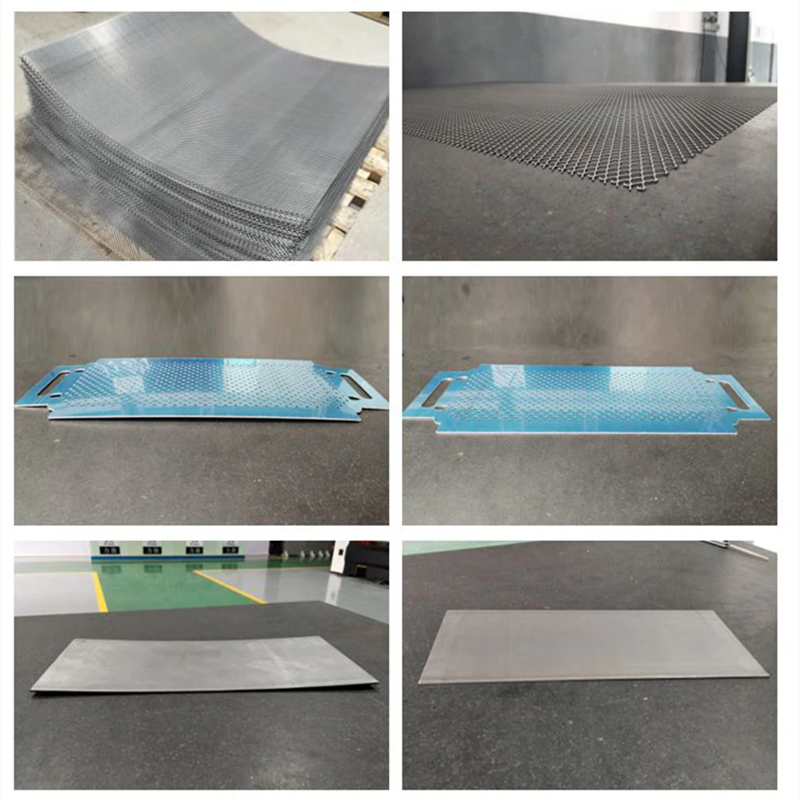

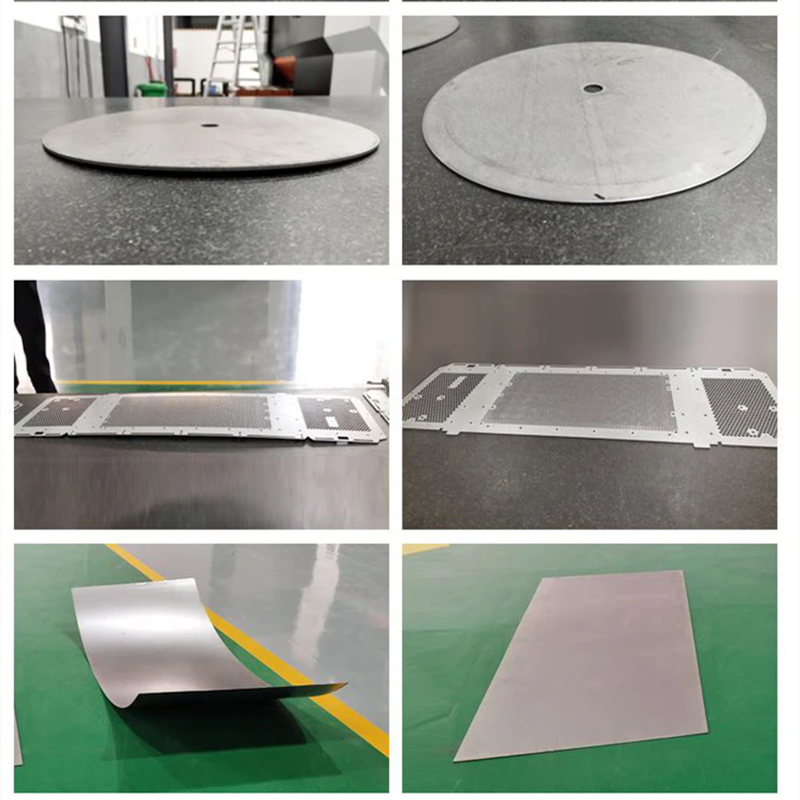

Precision levelers, often called plate and sheet metal roller levelers, are advanced machines designed to eliminate warping, bending, and distortion in metal sheets. These machines use a series of rollers and sophisticated technology to produce a flat, uniform surface on metal sheets or plates, ensuring they meet the required specifications. Ideal for use in industries that require high-quality sheet metal, including the automotive, construction, and aerospace sectors, precision levelers are essential for achieving the desired material flatness and surface quality.

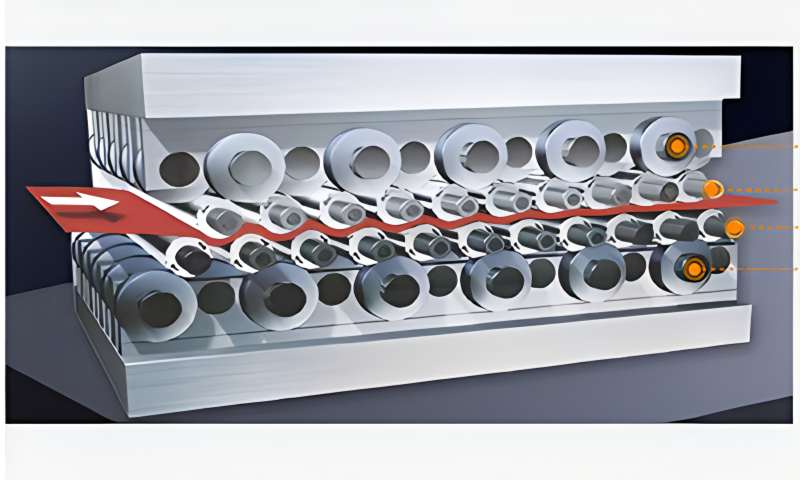

Overview of Roller Leveling Technology

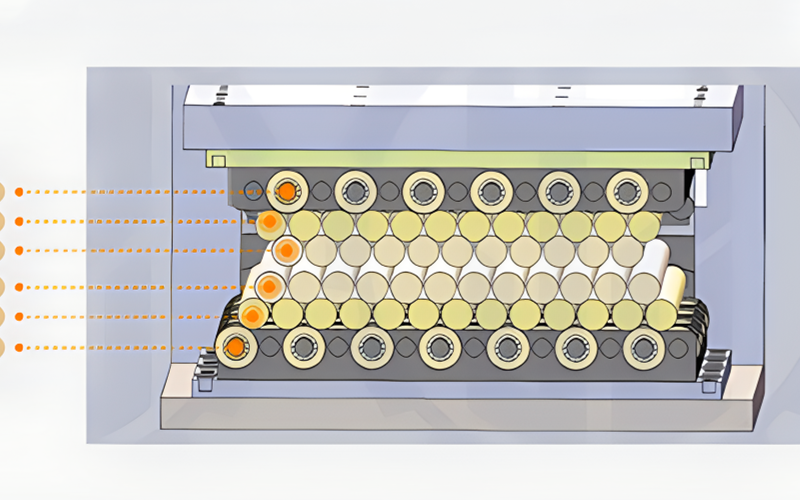

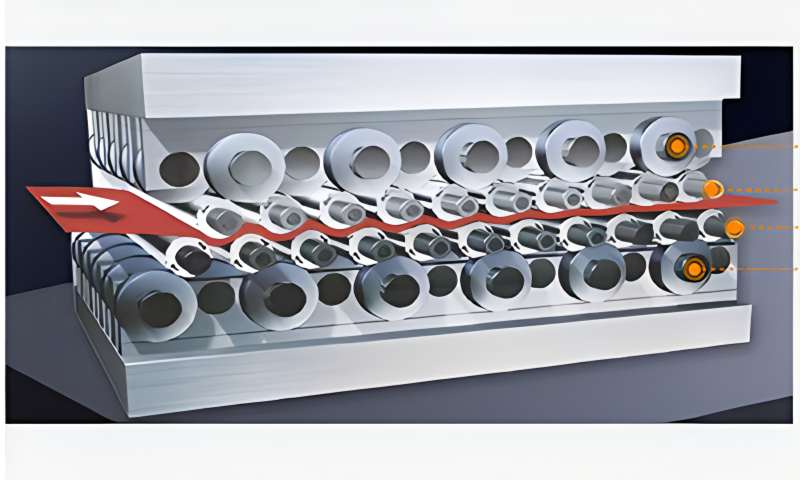

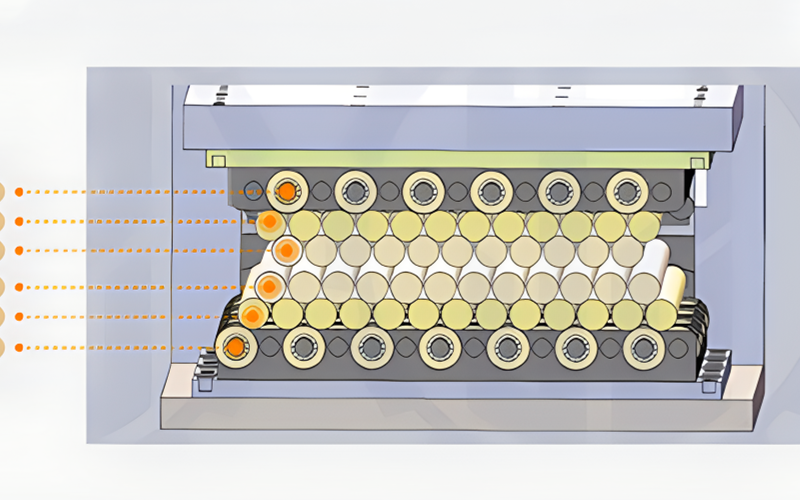

Roller leveling is a mechanical process where a series of rollers applies controlled pressure to metal sheets to straighten and flatten them. The sheets pass through multiple sets of rollers arranged in a specific sequence, each performing a particular function. The rollers progressively reduce the curvature of the sheet metal until it is completely flat.

In precision levelers, the rollers are designed to apply varying amounts of pressure depending on the sheet's thickness, material type, and specific flatness requirements. The process is ideal for materials ranging from 0.5mm to 2.5mm in thickness, ensuring high precision across a wide range of sheet sizes and applications.

Precision Levelers are advanced machines designed to correct flatness imperfections in metal plates and sheet materials. These machines are critical in industries where precise flatness and quality of metal sheets and plates are essential, such as automotive, aerospace, construction, and manufacturing.

Precision Roller Levelers

Adjustable Roller Gaps: One of the core features of these levelers is the ability to adjust the gap between rollers, allowing for customization based on the thickness of the material being processed. This helps in handling both thin sheets (0.5mm) and thicker ones (up to 2.5mm) with equal efficiency.

High-Quality Roller Materials: The rollers are typically made of high-strength alloy steel or other durable materials to withstand the wear and tear of constant use, especially when processing hard metals like steel and aluminum. Some machines also feature rollers with wear-resistant coatings to increase their lifespan.

CNC Automation: Most modern precision levelers are equipped with CNC (Computer Numerical Control) systems, which allow for automated adjustments and fine-tuning of the leveling process. This results in consistent, repeatable outcomes and reduces human error.

Wide Range of Sheet Widths: These levelers can accommodate metal sheets ranging from 200mm to 2200mm in width, providing flexibility in terms of material handling.

High Precision: With advanced sensors and control systems, these machines can achieve highly accurate leveling results, with tolerances often in the range of ±0.1mm or better, depending on the sheet thickness and material.

Efficient Operation: These levelers are designed for high throughput, ensuring that the leveling process is both fast and efficient, which is essential for large-scale production environments.

Applications of Precision Roller Levelers

Precision levelers are used across a variety of industries that require high-precision flatness in sheet metal. Some of the main applications include:

Automotive Industry: In the automotive sector, sheet metal is used for manufacturing car body parts, including doors, roofs, hoods, and chassis components. Precision levelers ensure that the sheets are perfectly flat and free of warps, which is essential for high-quality paint finishes and assembly processes.

Construction Industry: Steel plates used in construction projects, such as beams, columns, and other structural elements, often require leveling to ensure proper alignment and fit during assembly. Precision roller levelers are essential for ensuring these components meet the required standards.

Aerospace Industry: Aerospace components demand the highest levels of flatness and precision. Roller levelers are used to process thin and thick sheets of aluminum, titanium, and other lightweight metals, ensuring that they are ready for complex machining processes.

Electronics and Appliances: In the manufacturing of electronic devices and appliances, metal sheets must be perfectly flat to ensure proper assembly, functionality, and durability. Precision levelers are used in this context to prepare metal sheets for stamping, laser cutting, or other processes.

Metal Fabrication: Whether used for creating parts for machinery, tools, or industrial equipment, sheet metal leveling is crucial in the fabrication industry. A precision leveler ensures that the sheet metal can be cut, stamped, or welded with the utmost accuracy.

Types of Precision Levelers

There are different types of precision levelers based on their design and the nature of the leveling process. Some of the common types include:

Four-High Levelers: These machines use four rollers – two upper and two lower – to apply pressure to the metal sheet. The four-high system is typically used for thinner materials and offers better control over the leveling process.

Six-High Levelers: A six-high leveler includes additional rollers, which help to provide more precise leveling for thicker materials. These machines are suitable for materials in the 1.5mm to 2.5mm range and ensure high-quality results even for harder or more rigid metals.

Fully Automatic CNC Levelers: For industries that require mass production and consistent results, fully automated CNC precision levelers are ideal. These machines provide seamless integration with other production lines, offering automated leveling for large volumes of sheet metal.

Roller Levelers with Hydraulic Adjustment: These machines use hydraulic systems to adjust the roller positions automatically, allowing for fast changes in material thickness without the need for manual adjustments.

Advantages of Precision Levelers

Improved Material Quality: The primary benefit of using a precision roller leveler is the enhanced material quality. By flattening the metal sheet, the leveler helps to remove defects such as warping, bending, and residual stresses, resulting in a more stable and uniform product.

Increased Production Efficiency: High-precision roller levelers allow for faster and more consistent material processing, which improves overall production efficiency. This reduces the need for post-processing adjustments and lowers labor costs.

Customization for Specific Needs: Whether you need to level thin or thick metal sheets, precision levelers can be customized with adjustable settings to accommodate different material types and thicknesses, making them versatile and flexible.

Reduction in Material Wastage: A well-leveled sheet metal is easier to handle, cut, and process. This reduces the chances of errors during subsequent manufacturing processes, minimizing material wastage and scrap.

Enhanced Surface Quality: The leveling process smooths out the surface, making it ideal for subsequent processes such as coating, painting, or plating, ensuring the final product meets high-quality standards.

Key Considerations When Choosing a Precision Roller Leveler

When selecting a precision leveler for sheet metal, there are several factors to consider to ensure that the machine meets your specific needs:

Material Type: Some levelers are better suited for soft metals like aluminum, while others are designed for harder materials like stainless steel or titanium. Be sure to select a machine that can handle your material's hardness and properties.

Thickness Range: Make sure the leveler can accommodate the thickness range of the materials you typically work with. Some machines are better suited for thin sheets, while others are designed for thicker, more rigid plates.

Roller Configuration: Depending on the precision you need and the type of materials you process, you may need a four-high or six-high system. Machines with more rollers provide more control, which is particularly useful for thicker materials.

Automation Level: If you're operating in a high-production environment, fully automated or CNC-controlled levelers offer faster processing and better precision with minimal manual intervention.

Maintenance and Service: Regular maintenance is essential for ensuring the longevity of your precision leveler. Choose a machine with easy-to-service components and access to technical support.

200/400/600/800/1000/1200/1400/1600/1800/2000/2200mm Precision Levelers

Introduction to Precision Levelers

Precision levelers are vital tools in the metalworking industry, used to flatten, straighten, and level metal sheets, plates, or coils. They ensure that materials are free from distortions, warping, and residual stresses, offering superior quality for further manufacturing processes like welding, painting, and stamping. Precision levelers are commonly used for metals such as steel, aluminum, copper, and alloys, and are especially critical in industries that require high-quality materials, including automotive, aerospace, construction, and metal fabrication.

With wide applications across various industries, precision levelers are available in different sizes, capacities, and configurations to meet specific needs. The 200mm to 2200mm range of precision levelers allows for processing metal sheets of varying sizes and thicknesses, ensuring accuracy and quality control in the leveling process.

Key Features of Precision Levelers

Adjustable Roller Gaps

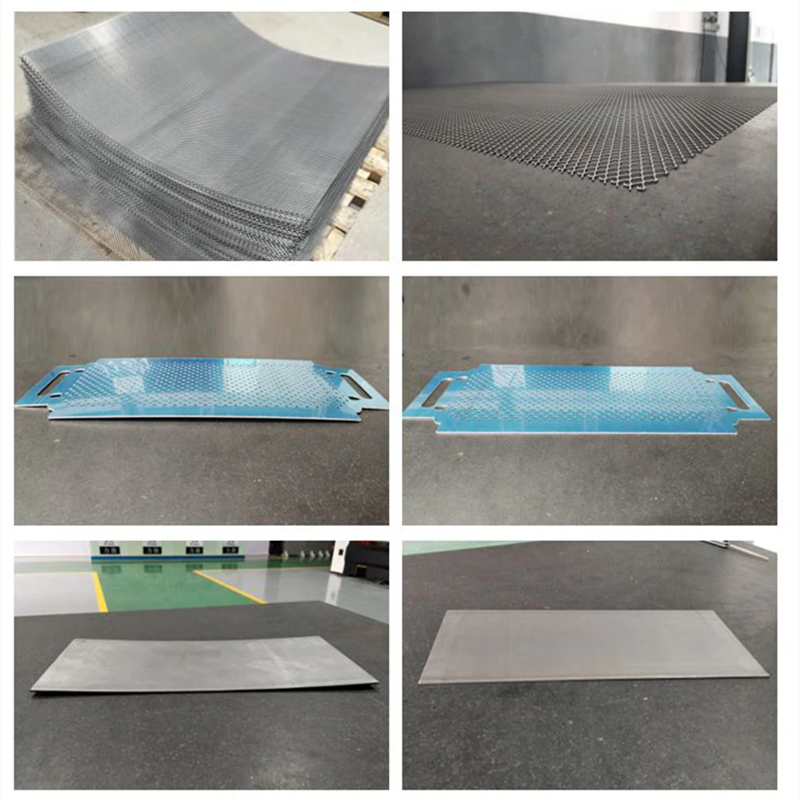

Precision levelers are designed with adjustable roller gaps to accommodate different sheet thicknesses. These gaps can be fine-tuned to provide optimal pressure and ensure a flat, uniform surface. Machines in the 200mm to 2200mm width range can handle both thin (0.5mm) and thick (up to 25mm) metals, offering versatility for various materials.

Multiple Rollers for High Precision

Precision levelers typically use a multi-roller system to flatten metal sheets. Machines in the range of 200mm to 2200mm width may include 4-high or 6-high roller configurations. These rollers apply precise pressure in a sequence that progressively reduces the curvature of the material, resulting in a highly accurate and smooth final product.

CNC Control

Many modern precision levelers are equipped with CNC (Computer Numerical Control) systems. This automation allows for precise control over the roller settings, gap adjustments, and machine speed. CNC-controlled levelers ensure that each sheet is processed with exacting accuracy, reducing the risk of human error and increasing consistency in large-scale production.

Wide Application Range

The precision leveler machines come in various sizes to handle metal sheets ranging from 200mm to 2200mm in width. These machines are highly adaptable to different sheet lengths and thicknesses, providing flexibility for processing diverse materials.

Superior Flatness and Material Quality

Precision levelers ensure superior flatness, which is critical for various downstream processes. Whether for metal coils, plates, or sheets, achieving flatness allows for precise cutting, stamping, or welding. Additionally, by removing internal stresses, these machines improve the material's mechanical properties, ensuring uniformity and reliability in the finished product.

High Throughput and Efficiency

For manufacturers handling large volumes of sheet metal, precision levelers provide high-speed processing capabilities, ensuring high throughput and efficiency. They also reduce material waste, as leveled sheets are easier to handle, cut, or form.

Applications of 200/400/600/800/1000/1200/1400/1600/1800/2000/2200mm Precision Levelers

Precision levelers are used across a wide variety of industries to process and flatten metal sheets and plates. Some of the primary applications include:

Automotive Industry

In the automotive industry, precision levelers are essential for preparing metal sheets used in car bodies, doors, chassis, and engine components. The levelers ensure that the metal is flat and free from distortion, which is crucial for ensuring accurate assembly and superior paint finishes.

Aerospace Industry

Aerospace manufacturers rely on precision levelers to process thin and thick sheets of aluminum, titanium, and other alloys. The highly accurate leveling achieved by these machines ensures that critical aerospace components meet the stringent requirements for safety, performance, and durability.

Construction and Structural Applications

In construction, steel plates used for beams, columns, and other structural elements must be perfectly flat to ensure proper fitting during assembly. Precision levelers ensure the sheets meet these structural requirements with accuracy and reliability.

Metal Fabrication

Metal fabrication companies that work with sheet metal need to flatten materials before further processing. Precision levelers enable fabricators to produce metal parts with high dimensional accuracy, ensuring quality welding, cutting, and bending operations.

Electronics and Appliances

Sheet metal used in electronics, appliances, and other consumer products must meet strict flatness requirements to ensure proper assembly and function. Precision levelers are ideal for preparing metal for this type of manufacturing.

Energy and Power Generation

In the power generation industry, especially in the production of equipment such as pressure vessels, turbines, and heat exchangers, precision levelers help to create the flat, distortion-free metal surfaces needed for complex welding and assembly operations.

Key Benefits of Precision Levelers

Increased Precision and Quality

The primary advantage of using a precision leveler is the high level of flatness it provides, which is essential for industries that rely on accurate metal sheet processing. The smooth, uniform surface ensures that the metal is ready for additional manufacturing processes, reducing the need for rework or adjustments.

Enhanced Material Durability

By eliminating internal stresses and distortions, precision levelers improve the overall mechanical properties of the material. This ensures that the material is stronger, more durable, and less prone to warping during subsequent processing steps.

Faster Turnaround Times

CNC-controlled precision levelers offer automated adjustments, allowing manufacturers to process large batches of sheet metal quickly and with minimal downtime. The automated systems adjust parameters based on the material type and thickness, which reduces the setup time and increases throughput.

Versatility Across Different Sheet Sizes and Materials

Precision levelers in the range of 200mm to 2200mm in width can process a wide variety of materials, including steel, aluminum, stainless steel, and non-ferrous alloys. They can handle sheets of different thicknesses, ranging from 0.5mm to 25mm, ensuring flexibility across a broad spectrum of applications.

Reduced Waste and Rework

Since precision levelers ensure consistent flatness, they reduce the need for post-processing adjustments, leading to less material waste and fewer defective products. This ultimately saves costs and improves production efficiency.

Types of Precision Levelers

Four-High Precision Levelers

These machines consist of four rollers (two upper and two lower) that apply pressure to the metal sheet. Four-high systems are typically used for thinner sheets, offering excellent precision for sheet thicknesses from 0.5mm to 6mm.

Six-High Precision Levelers

With additional rollers, six-high systems are designed for thicker sheets or materials with a higher rigidity. These machines can process sheets up to 25mm thick, making them ideal for heavy-duty applications.

CNC-Controlled Precision Levelers

Many precision levelers are now equipped with CNC systems that allow for automatic adjustments of roller gaps, machine speed, and pressure, ensuring consistent results across multiple batches of material.

Hydraulic Levelers

Hydraulic precision levelers are equipped with hydraulic adjustments, which allow for fine control over the roller gaps, offering high flexibility for different materials and thicknesses.