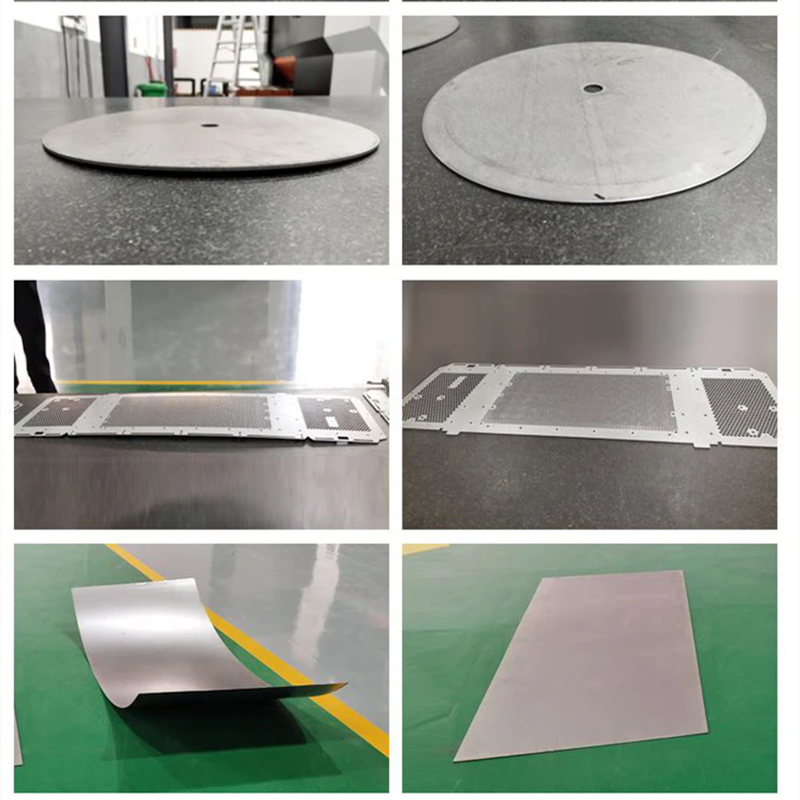

Wide Processing Range (200mm-1300mm):

The levelers are designed to process metal sheets with widths ranging from 200mm to 1300mm, providing versatility for small to large-scale production runs. Ideal for applications in industries such as automotive, construction, and precision manufacturing.

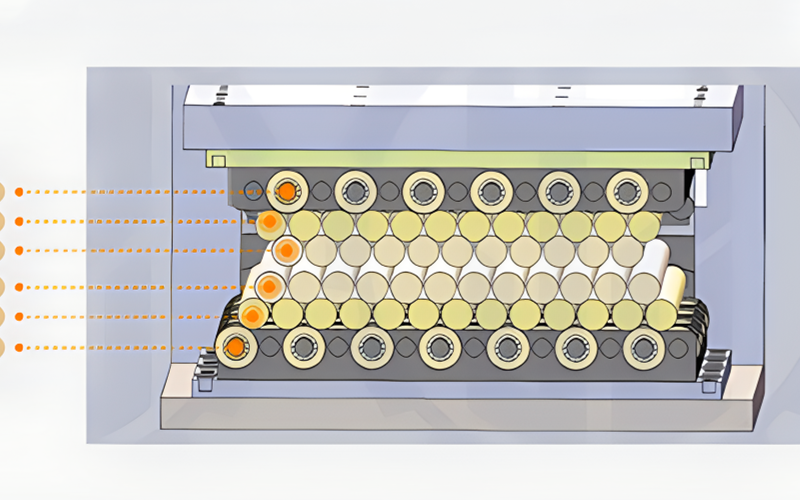

CNC Precision Control:These levelers are equipped with CNC (Computer Numerical Control) technology, ensuring consistent, repeatable results. The CNC system allows for accurate adjustments in real-time, optimizing the leveling process for precision flatness and minimal surface deformation.

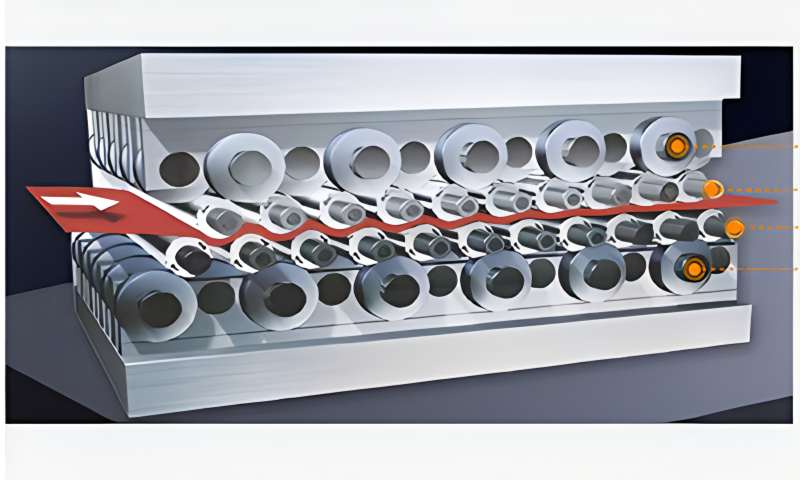

Four-High and Six-High Roll Configurations:

Four-High Roll:

This configuration utilizes four rolls (two upper and two lower rolls) for leveling thin sheet metal. It is suitable for general metal processing where moderate precision is required.

Six-High Roll:

A more advanced configuration, the six-high roll setup includes six rolls (four working rolls and two backup rolls), providing superior flatness control. Ideal for processing high-strength or thin materials where utmost precision is critical.

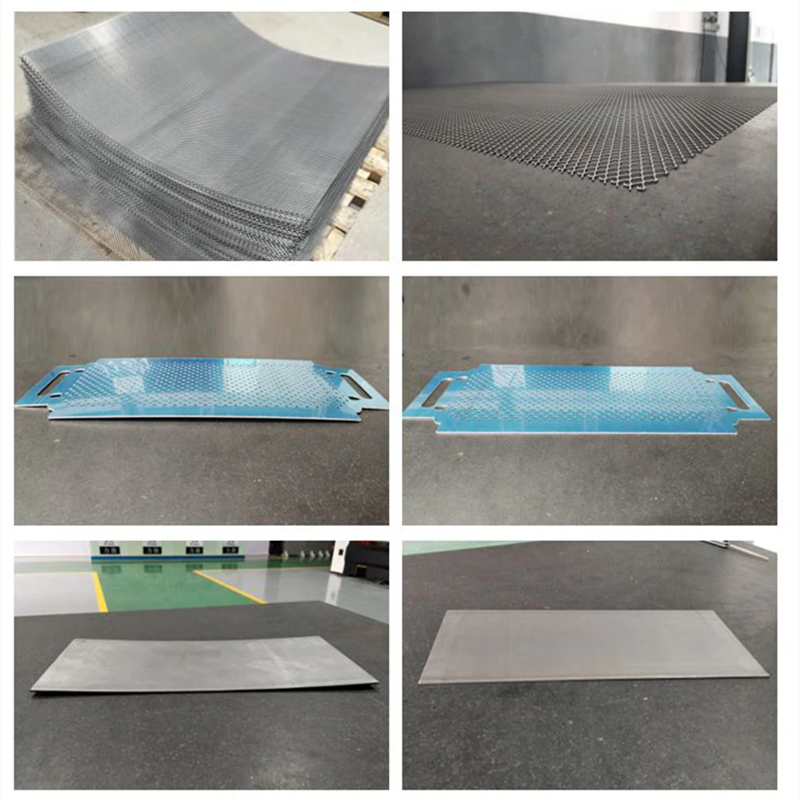

High-Level Flatness and Straightness:These high-precision levelers are engineered to achieve superior flatness and straightness on metal sheets. This is crucial for industries that require exact material geometry, such as automotive manufacturing and precision metalworking.

Advanced Roll Gap Control:The CNC system offers precise roll gap adjustments, optimizing the leveling force to maintain the required flatness. This ensures that the metal sheets are leveled with minimal stress, preventing damage to the material while achieving the desired shape.

Wide Material Compatibility:The machines are designed for a range of materials, including steel, aluminum, stainless steel, titanium, and more. Whether you are processing thin or thick sheets, these levelers can handle various material properties with ease.

Energy-Efficient and Environmentally Friendly:With an emphasis on energy efficiency, these high-precision levelers reduce operational costs and minimize the environmental impact by using low-power motors and advanced control systems that ensure optimized energy usage.

Automatic Feed and Exit Systems:The levelers feature automatic feeding and exit systems for efficient material handling. This increases productivity by allowing continuous operation and reducing downtime between material loading and unloading.

Durability and Longevity:Built with robust, high-strength components, these levelers offer long-term reliability. The advanced roll material and precision machining techniques ensure high durability even under heavy usage.