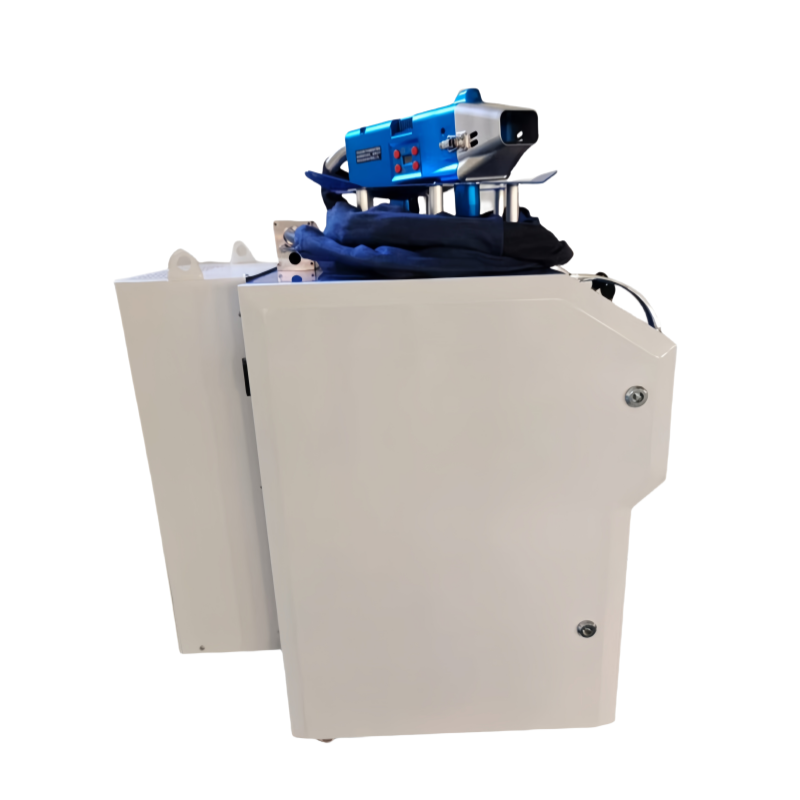

200W Handheld Laser Cleaning Machine

1. Basic Operating Environment

| Content | Parameter |

|---|

| Power Supply Voltage | Single-phase 220V ±10%, 50/60Hz AC |

| Total Power Consumption | < 1800W |

| Placement Environment | Flat, vibration-free, no impact |

| Operating Temperature | 0°C to 40°C |

| Operating Humidity | ≤ 80% |

2. Optical Parameters

| Content | Parameter |

|---|

| Laser Average Power | 200W |

| Power Instability | < 3% |

| Power Adjustment Range | 0-100% (gradually adjustable) |

| Focusing Spot Diameter | 0.2mm |

| Center Wavelength | 1064nm |

| Modulation Frequency | 67KHz-4000KHz (gradually adjustable) |

| Fiber Length | 10M |

| Cleaning Mode | 6 modes, freely switchable |

| Cooling Method | Air cooling |

| Operating Temperature | 5°C to 40°C |

200W Portable Laser Cleaning Machine is a versatile and efficient tool for removing stains, rust, and paint from various surfaces.

Functions:

Rust Removal: Effectively removes rust from metal surfaces without causing damage to the underlying material.

Paint Removal: Easily removes old paint, coatings, or varnish from different surfaces, restoring the original material.

Oil Stain and Contaminant Cleaning: Cleans oil stains, grease, and other contaminants from the surface of materials.

Oxide Film Removal: Removes oxide layers from metals, ensuring a clean and smooth surface.

Surface Preparation: Prepares the surface for further treatments, such as coating, bonding, or welding.

Applications:

Wood Products: Suitable for cleaning and removing contaminants or paint from wooden surfaces, especially those with intricate designs.

Thin Metal Sheets: Effectively removes stains, rust, and coatings from thin metal sheets, ideal for applications where precision is critical.

Precision Fittings: Used for cleaning delicate precision parts, such as molds and gears, without damaging fine details or surface integrity.

Automotive Industry: Ideal for cleaning automotive components such as metal parts, gears, and rusted surfaces.

Aerospace and Manufacturing: Removes contaminants from parts and components used in aerospace, automotive, and machinery manufacturing.

Electronics and Electrical Equipment: Cleans metal parts and fittings in the production of electronic devices and electrical equipment.

Maintenance and Repair: Used for cleaning and restoring tools, machinery, and parts in various industries, ensuring they remain in optimal working condition.

Operation:

Portability: The machine is designed to be lightweight and portable, allowing it to be used for a variety of on-site cleaning tasks.

User-Friendly Interface: The machine is equipped with an easy-to-use interface, making it accessible for users of all experience levels.

Power Adjustment: The output power is adjustable to cater to different materials and cleaning needs, offering a range from 0 to 100% power.

Cooling System: Features an efficient air-cooling system to ensure the machine operates at optimal temperatures during extended use.

Cleaning Mode Selection: The machine offers multiple cleaning modes, allowing the user to select the most appropriate mode for the surface and type of contamination.

Maintenance: The design is simple and easy to maintain, with parts that can be easily replaced, ensuring minimal downtime and maximum operational efficiency.

This 200W Portable Laser Cleaning Machine is ideal for a wide range of industries, offering high precision, efficiency, and ease of use for cleaning, rust removal, and surface preparation.